I've been looking at the 23qt presto canner, I'll probably pull the trigger after the holidays.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Weissbier Schneider & Sohn Original German Hefe Weizen Ale

- Thread starter Schlenkerla

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

lump42

The Lajestic Vantrashell of Lob

I believe the issue is that the instant pot/ electric pressure cookers don't get to high enough pressure and they monitor only pressure, so people in higher elevations won't hit the required temps. My office teaches home canning classes and the instructor, said they only get to 11 psi. The pressure and temps together are required to kill botulinum spores. I'm sure many here will say they've done it and been fine. However, with any risk, you're fine until you're not. If you adjusted the starter wort pH lower than 4.6 than it would be safe, but otherwise it would be safer to use a traditional pressure canner. Additional benefit of an actual pressure canner is that they can usually hold more jars, so less canning runs would need to be made.Well, some HBT members say that the instant pot doesn't get hot enough to kill botulism. 230F vs 250F. The required heat threshold is 250 I'm told.

I accidentally set it for 5 hours when I wanted it 5 minutes.

I'm going to re-cook my starters in my presto pressure cooker on high with the fvcker blowing steam and with the dancing weight diddyboopin' about. Maybe 20 minutes.

I was thinking that hitting 15 psi at over 212F would kill anything.

Mate, Sohn is not a name, it means son.I'd say it's worth a try.

Worse case is I have 5 gallons of a good German Hefe Weizen that's a redheaded stepchild of Herr Schneider or Herr Sohn.

Schneider and son.

I'd be tempted to adjust the wort pH down to an appropriate level for water bath canning, then when ready to use correct it back up to ~5.2 with sodium bicarbonate. Would that work?I believe the issue is that the instant pot/ electric pressure cookers don't get to high enough pressure and they monitor only pressure, so people in higher elevations won't hit the required temps. My office teaches home canning classes and the instructor, said they only get to 11 psi. The pressure and temps together are required to kill botulinum spores. I'm sure many here will say they've done it and been fine. However, with any risk, you're fine until you're not. If you adjusted the starter wort pH lower than 4.6 than it would be safe, but otherwise it would be safer to use a traditional pressure canner. Additional benefit of an actual pressure canner is that they can usually hold more jars, so less canning runs would need to be made.

lump42

The Lajestic Vantrashell of Lob

I believe so. There are alot of water bath jam/jelly recipes that include lemon juice or citric acid to drop the pH. From my understanding from talking with our instructor, what is being canned is less important than the pH and the size of the pieces being canned. The acidic food, water bath canning won't kill the botulinum, but the acidic environment prevents the botulinum bacteria from growing. For ease of adjusting, I would use soft or distilled water for the starter so you aren't contending with buffering capacity of hard water.I'd be tempted to adjust the wort pH down to an appropriate level for water bath canning, then when ready to use correct it back up to ~5.2 with sodium bicarbonate. Would that work?

I would be using RO water and extra light DME, or maybe I'll just mash some pilsner malt. Also thinking of doubling the OG and diluting with bottled water when I make a starter, so I can vary the gravity as appropriate in order to step it up.I believe so. There are alot of water bath jam/jelly recipes that include lemon juice or citric acid to drop the pH. From my understanding from talking with our instructor, what is being canned is less important than the pH and the size of the pieces being canned. The acidic food, water bath canning won't kill the botulinum, but the acidic environment prevents the botulinum bacteria from growing. For ease of adjusting, I would use soft or distilled water for the starter so you aren't contending with buffering capacity of hard water.

On a side note, I've always heard that underpitching will boost the yeast character in a Hefeweizen but IME has produced off flavors. Next batch I'm going to pitch a healthy starter and ferment open.

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,916

I recooked my starters last night. I'm ready to test a one of the spent bottles.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,916

That's good to know I wasn't sure which one it was.Mate, Sohn is not a name, it means son.

Schneider and son.

Did it spoil the joke for you?

Nope, made it funnier.That's good to know I wasn't sure which one it was.

Did it spoil the joke for you?

Sohn is also a common surname, so it is conceivable that two men, one named Schneider and the other Sohn, could jointly open a brewery even though Mr. Schneider has only daughtersMate, Sohn is not a name, it means son.

Schneider and son.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,916

OK today I took a small sample of wort and dregs of one bottle and put on my hobo stir plate.

Here's what I did:

1) I started by pressure cooking my milk bottle, stir-bar and my stainless funnel. When done I removed the bottle and let it cool. Leaving the funnel in the pressure cooker and put the lid back on.

2) Then added 2-3 ounces of wort. It was running for a few minutes with just the 1.040 wort. It ran without any foam buildup.

3) I had about a teaspoon of dregs in the bottle. Using the funnel and tongs, I added an ounce of distilled water stirred it a bit, then, put the funnel on the milk bottle, and then I poured in the dregs into the stir plate milk bottle..

Within minutes the contents of the stir plate started to foam up. See photo.

I don't plan to use this since I'm not brewing until January and the bottle was open and unprotected for several days. If this is any indication that using the dregs will work, this is starting to look good.

Here's what I did:

1) I started by pressure cooking my milk bottle, stir-bar and my stainless funnel. When done I removed the bottle and let it cool. Leaving the funnel in the pressure cooker and put the lid back on.

2) Then added 2-3 ounces of wort. It was running for a few minutes with just the 1.040 wort. It ran without any foam buildup.

3) I had about a teaspoon of dregs in the bottle. Using the funnel and tongs, I added an ounce of distilled water stirred it a bit, then, put the funnel on the milk bottle, and then I poured in the dregs into the stir plate milk bottle..

Within minutes the contents of the stir plate started to foam up. See photo.

I don't plan to use this since I'm not brewing until January and the bottle was open and unprotected for several days. If this is any indication that using the dregs will work, this is starting to look good.

Last edited:

Cannot be that common in Germany. Never heard of somebody called Sohn and never met one, but it is of course a possibility.Sohn is also a common surname, so it is conceivable that two men, one named Schneider and the other Sohn, could jointly open a brewery even though Mr. Schneider has only daughters

Last edited:

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,916

You never heard of John Sohn?Cannot be that common in Germany. Never heard about somebody called Sohn and never met one, but it is of course a possibility.

dawn_kiebawls

Lawncare and Landscaping enthusiast

- Joined

- Jun 10, 2017

- Messages

- 838

- Reaction score

- 519

Thanks for this awesome tutorial and recipe, can't wait to try it! A few questions though:

1) I do the 10g igloo mash tun, would it make sense to just mash in my kettle on the heat source, dump into igloo cooler, vorlauf and batch sparge? If not, would it make sense to do a decoction? Though I guess that would be more work and a similar process as far as transferring from kettle to tun goes..

2) When you say to cover the fermentor for the first 8 hours, do you mean with cheese cloth or to just rest the lid on it?

2a) After the first 8 hours do I just completely uncover it or put the lid/airlock on? (I've never open fermented so I apologize if this is a dumb question)

3) I'm not going to crop any of the yeast. Should I still remove high krausen or can I just push it to the side?

4) What is your efficiency when brewing this recipe? 1.052 seems high from only 8lbs of grist but I'm not sure. The reason I'm asking is the 'Bee Cave Hefe' recipe on here has an 11lb grain bill with the same OG.

5) I'm assuming the link you posted for the priming calculator was already programmed with the recipe data, so I would need to reserve 1.27q of wort. Correct?

6) I've never used wort to prime either, after it carbs to 2 volumes what do you set the serving pressure to?

Sorry for the barrage of questions! Hope to hear back from you soon so I can get this thing going ASAP! (who cares if its out of season? I want a proper hefe on tap NOW! ) Thanks again, cheers.

) Thanks again, cheers.

1) I do the 10g igloo mash tun, would it make sense to just mash in my kettle on the heat source, dump into igloo cooler, vorlauf and batch sparge? If not, would it make sense to do a decoction? Though I guess that would be more work and a similar process as far as transferring from kettle to tun goes..

2) When you say to cover the fermentor for the first 8 hours, do you mean with cheese cloth or to just rest the lid on it?

2a) After the first 8 hours do I just completely uncover it or put the lid/airlock on? (I've never open fermented so I apologize if this is a dumb question)

3) I'm not going to crop any of the yeast. Should I still remove high krausen or can I just push it to the side?

4) What is your efficiency when brewing this recipe? 1.052 seems high from only 8lbs of grist but I'm not sure. The reason I'm asking is the 'Bee Cave Hefe' recipe on here has an 11lb grain bill with the same OG.

5) I'm assuming the link you posted for the priming calculator was already programmed with the recipe data, so I would need to reserve 1.27q of wort. Correct?

6) I've never used wort to prime either, after it carbs to 2 volumes what do you set the serving pressure to?

Sorry for the barrage of questions! Hope to hear back from you soon so I can get this thing going ASAP! (who cares if its out of season? I want a proper hefe on tap NOW!

HawleyFarms

Well-Known Member

Someone is confused. The 95 degree mash step does not produce ferulic acid. At that temperature there are only two enzymes working: phytase (which produces phytic acid, used as an old school way of lowering mash pH over a period of several hours) and glucanase (which breaks down gummy beta glucans).

The 122 degree mash step is the ferulic acid producing step. At that temperature is where peptidase, the enzyme responsible for producing ferulic acid, is active

The 122 degree mash step is the ferulic acid producing step. At that temperature is where peptidase, the enzyme responsible for producing ferulic acid, is active

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,916

I don't know, I have two books that say the same thing. One by Chris Colby by BYO and the other is by Jeff Alworth. Both say to mash in low. Both call it a ferulic acid rest.Someone is confused. The 95 degree mash step does not produce ferulic acid. At that temperature there are only two enzymes working: phytase (which produces phytic acid, used as an old school way of lowering mash pH over a period of several hours) and glucanase (which breaks down gummy beta glucans).

The 122 degree mash step is the ferulic acid producing step. At that temperature is where peptidase, the enzyme responsible for producing ferulic acid, is active

Even the brewer from Schneider & Sohn calls it that.

They start at 95F and expect the mash tun temps to be risen to 104-113F for the ferulic rest. They go on to say the upper threshold is 122F for the ferulic rest and the creation of that phenolic character. They recommend about 10 minutes to not over do the phenol balance.

I haven't made it yet and I can't attest to how that works chemistry wise. I also need to decide how to Mash it. Being direct heat or a series of infusions. I'm thinking of direct heat. I need a brew kettle modification to make that work.

Last edited:

HawleyFarms

Well-Known Member

I don't know, I have two books that say the same thing. One by Chris Colby by BYO and the other is by Jeff Alworth. Both say to mash in low. Both call it a ferulic acid rest.

Even the brewer from Schneider & Sohn calls it that.

They start at 95F and expect the mash tun temps to be risen to 104-113F for the ferulic rest. They go on to say the upper threshold is 122F for the ferulic rest and the creation of that phenolic character. They recommend about 10 minutes to not over do the phenol balance.

I haven't made it yet and I can't attest to how that's works chemistry wise. I also need to decide how to Mash it. Being direct heat or a series of infusions. I'm thinking of direct heat. I need a brew kettle modification to make that work.

95f IS known as the acid rest, but not for the creation of ferulic acid. That temp is mostly used to break down beta glucans. True ferulic acid production will not start until 104 and isn't being heavily produced until 113-115 with 122-128 being the high range of peptidase. Peptidase is a proteolytic enzyme (hence it being called protein rest #1 in this recipe) and will not even begin working at 95f. The information is out there. The problem is all these authors are just repeating what is being written in previous books and are mistaking the term 'Acid Rest' for the production of ferulic acid, when in fact only phytic acid is being produced at that temperature. If you dough in at 95f but intend to raise the temps to between 104-113, then they are using direct fire and should be calling it what it is: a beta glucan rest followed by a rise in temperature for a ferulic acid rest. I could link to a dozen scientific studies showing that peptidase is NOT active in the 95f range.

HawleyFarms

Well-Known Member

This is a great blog on understanding step mashing and what enzymes are active at what temperatures, although I believe some of the temperatures are slightly off http://counterbrew.blogspot.com/2016/05/a-beer-geek-guide-to-step-mashing.html?m=1

HawleyFarms

Well-Known Member

And here is an article written by the author you mentioned (Jeff Alworth) http://allaboutbeer.com/quirks-of-brewing-ferulic-acid-rest/

HawleyFarms

Well-Known Member

And to further complicate matters, the production of ferulic acid favors a higher pH than the often strived for 5.2. If you are in the habit of adjusting mash pH, it's a wise idea to wait until after you have done the ferulic acid rest.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,916

I believe you. I'm guessing most authors are taking notes from pros who are not chemist, just brewers or they get the notes wrong.95f IS known as the acid rest, but not for the creation of ferulic acid. That temp is mostly used to break down beta glucans. True ferulic acid production will not start until 104 and isn't being heavily produced until 113-115 with 122-128 being the high range of peptidase. Peptidase is a proteolytic enzyme (hence it being called protein rest #1 in this recipe) and will not even begin working at 95f. The information is out there. The problem is all these authors are just repeating what is being written in previous books and are mistaking the term 'Acid Rest' for the production of ferulic acid, when in fact only phytic acid is being produced at that temperature. If you dough in at 95f but intend to raise the temps to between 104-113, then they are using direct fire and should be calling it what it is: a beta glucan rest followed by a rise in temperature for a ferulic acid rest. I could link to a dozen scientific studies showing that peptidase is NOT active in the 95f range.

I'm thinking follow the method they use to make a clone. Hell with the names of the steps. You'd think you'd want them named properly.

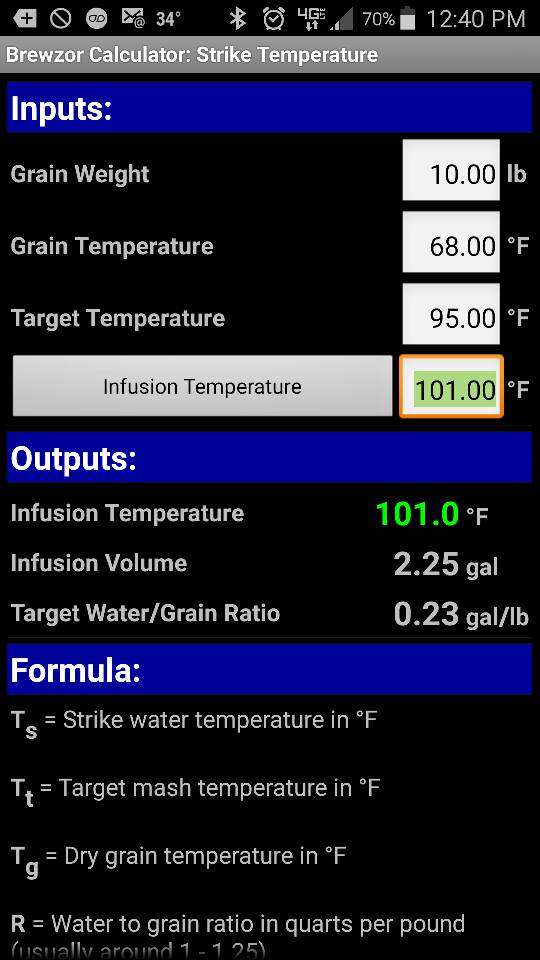

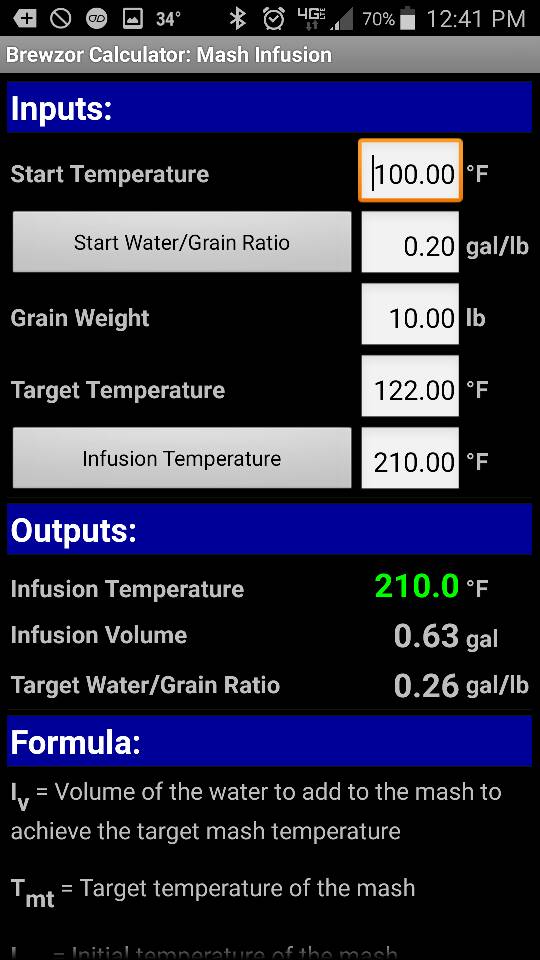

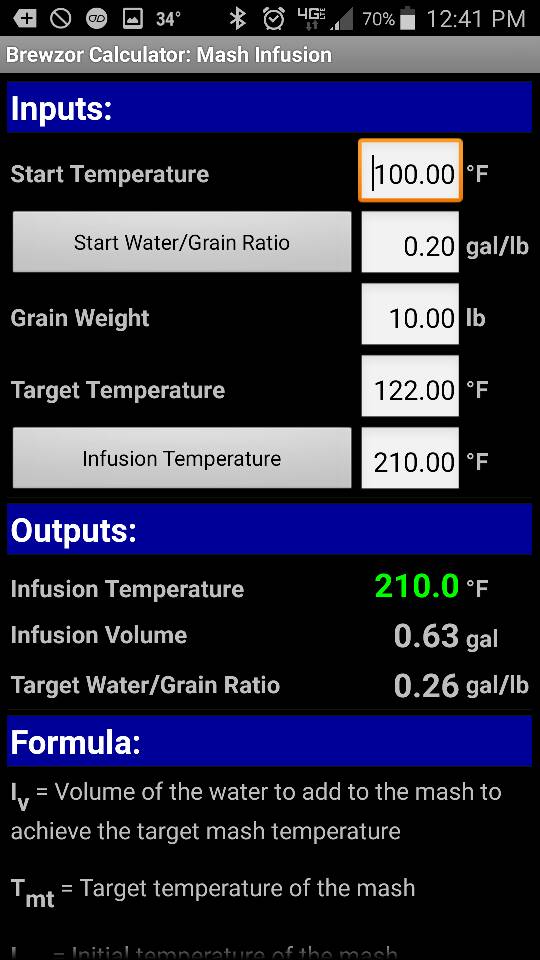

The thing that is most confusing is the means to hit temps via infusion and starting at what ratio quart per pound.

Where do you start? 1/2 quart per pound?

I haven't done a lot of step mashing intentionally. Typically I do it when I lose too much heat and need to kick up the temp in the cooler.

I haven't found a good multi step mash calculator online yet. I have the formulas in a brewing app. Could make a spreadsheet.

This thought is what is pushing me direct heat mashing in a kettle.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,916

This guy calls an acid rest 95-113F....This is a great blog on understanding step mashing and what enzymes are active at what temperatures, although I believe some of the temperatures are slightly off http://counterbrew.blogspot.com/2016/05/a-beer-geek-guide-to-step-mashing.html?m=1

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,916

Thanks for all the sharing...

Like both of those articles. Especially the step mash one.

Jeff Alworth's comments are like that of the book I cited on post#1. Mentioning Hans-Peter Drexler and what not....

Like both of those articles. Especially the step mash one.

Jeff Alworth's comments are like that of the book I cited on post#1. Mentioning Hans-Peter Drexler and what not....

HawleyFarms

Well-Known Member

This guy calls an acid rest 95-113F....

Yes, read his description of what an acid rest details. Phytic acid, NOT ferulic acid. The traditional acid rest was used as a means of adjusting mash pH over a period of several hours, not for the production of ferulic acid.

HawleyFarms

Well-Known Member

Thanks for all the sharing...

Like both of those articles. Especially the step mash one.

Jeff Alworth's comments are like that of the book I cited on post#1. Mentioning Hans-Peter Drexler and what not....

Then Jeff Alworth is contradicting himself in the original recipe in post #1 by saying that a rest a 95f has anything to do with ferulic acid production.

HawleyFarms

Well-Known Member

This guy calls an acid rest 95-113F....

He goes on to state that in the proteolytic enzyme explanations that peptidase is the key enzyme responsible for ferulic acid production and if you want to maximize the production of phenols in Hefeweizen, you should be doing a peptidase rest at 115 when the enzyme peptidase is most active.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,916

How do you do step mashes?He goes on to state that in the proteolytic enzyme explanations that peptidase is the key enzyme responsible for ferulic acid production and if you want to maximize the production of phenols in Hefeweizen, you should be doing a peptidase rest at 115 when the enzyme peptidase is most active.

Direct heat

Infusion with boiling water and specific volume

Infusion with specific volume and temp.

Decoction

HawleyFarms

Well-Known Member

How do you do step mashes?

Direct heat

Infusion with boiling water and specific volume

Infusion with specific volume and temp.

Decoction

Boiling water infusions. I only have a 10 gallon cooler with false bottom for mashing and have a 5 gallon kettle that I use for boiling water infusions and sparking and a 16 gallon kettle for boiling. I rarely ever do a single infusion mash anymore, almost always step mash. I do a beta glucan rest on nearly every single beer I make as well. I occasionally so decoction mashes as well if the style calls for it. For a hefeweizen, I usually go 95, 115, 134, and 152 and the a mash out infusion of 170 to turn off the enzymes before recirculating and draining the tun. With that many steps using boiling water infusions, you really want to turn off the enzymes so you can more easily rinse the sugars off since you aren't going to have a lot of sparging to do, if at all, before going over your intended pre-boil volume. Step mashing tends to make for an extremely efficient mash as well. I'it's not uncommon to have full mash extraction. Since beginning step mashing, I'm often in the low to mid 90's for overall brew house efficiency.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,916

What's your starting ratio of water to grain at 95F?Boiling water infusions. I only have a 10 gallon cooler with false bottom for mashing and have a 5 gallon kettle that I use for boiling water infusions and sparking and a 16 gallon kettle for boiling. I rarely ever do a single infusion mash anymore, almost always step mash. I do a beta glucan rest on nearly every single beer I make as well. I occasionally so decoction mashes as well if the style calls for it. For a hefeweizen, I usually go 95, 115, 134, and 152 and the a mash out infusion of 170 to turn off the enzymes before recirculating and draining the tun. With that many steps using boiling water infusions, you really want to turn off the enzymes so you can more easily rinse the sugars off since you aren't going to have a lot of sparging to do, if at all, before going over your intended pre-boil volume. Step mashing tends to make for an extremely efficient mash as well. I'it's not uncommon to have full mash extraction. Since beginning step mashing, I'm often in the low to mid 90's for overall brew house efficiency.

Do you use a step calculator to figure out the volumes? If so what do you use?

I use an Android app. Brewzor calculator. It has the strike and mash infusion and decoction volumes and bunch of other stuff.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,916

This is the step mash...

Similar threads

- Replies

- 11

- Views

- 6K

- Replies

- 4

- Views

- 5K

- Replies

- 17

- Views

- 11K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)