Thanks for this awesome tutorial and recipe, can't wait to try it! A few questions though:

1) I do the 10g igloo mash tun, would it make sense to just mash in my kettle on the heat source, dump into igloo cooler, vorlauf and batch sparge? If not, would it make sense to do a decoction? Though I guess that would be more work and a similar process as far as transferring from kettle to tun goes..

2) When you say to cover the fermenter for the first 8 hours, do you mean with cheese cloth or to just rest the lid on it?

2a) After the first 8 hours do I just completely uncover it or put the lid/airlock on? (I've never open fermented so I apologize if this is a dumb question)

3) I'm not going to crop any of the yeast. Should I still remove high krausen or can I just push it to the side?

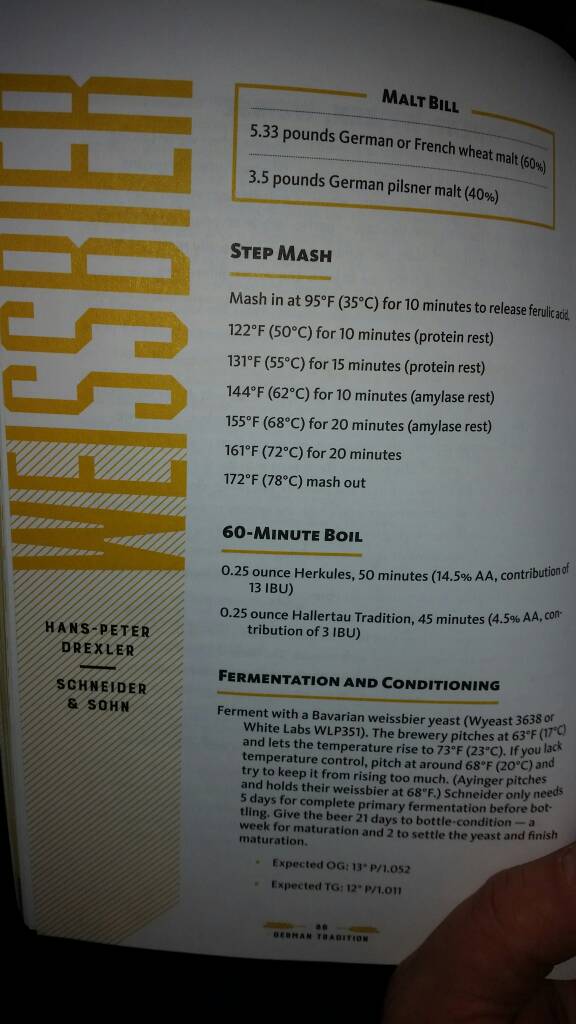

4) What is your efficiency when brewing this recipe? 1.052 seems high from only 8lbs of grist but I'm not sure. The reason I'm asking is the 'Bee Cave Hefe' recipe on here has an 11lb grain bill with the same OG.

5) I'm assuming the link you posted for the priming calculator was already programmed with the recipe data, so I would need to reserve 1.27q of wort. Correct?

6) I've never used wort to prime either, after it carbs to 2 volumes what do you set the serving pressure to?

Sorry for the barrage of questions! Hope to hear back from you soon so I can get this thing going ASAP! (who cares if its out of season? I want a proper hefe on tap NOW!

) Thanks again, cheers.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)