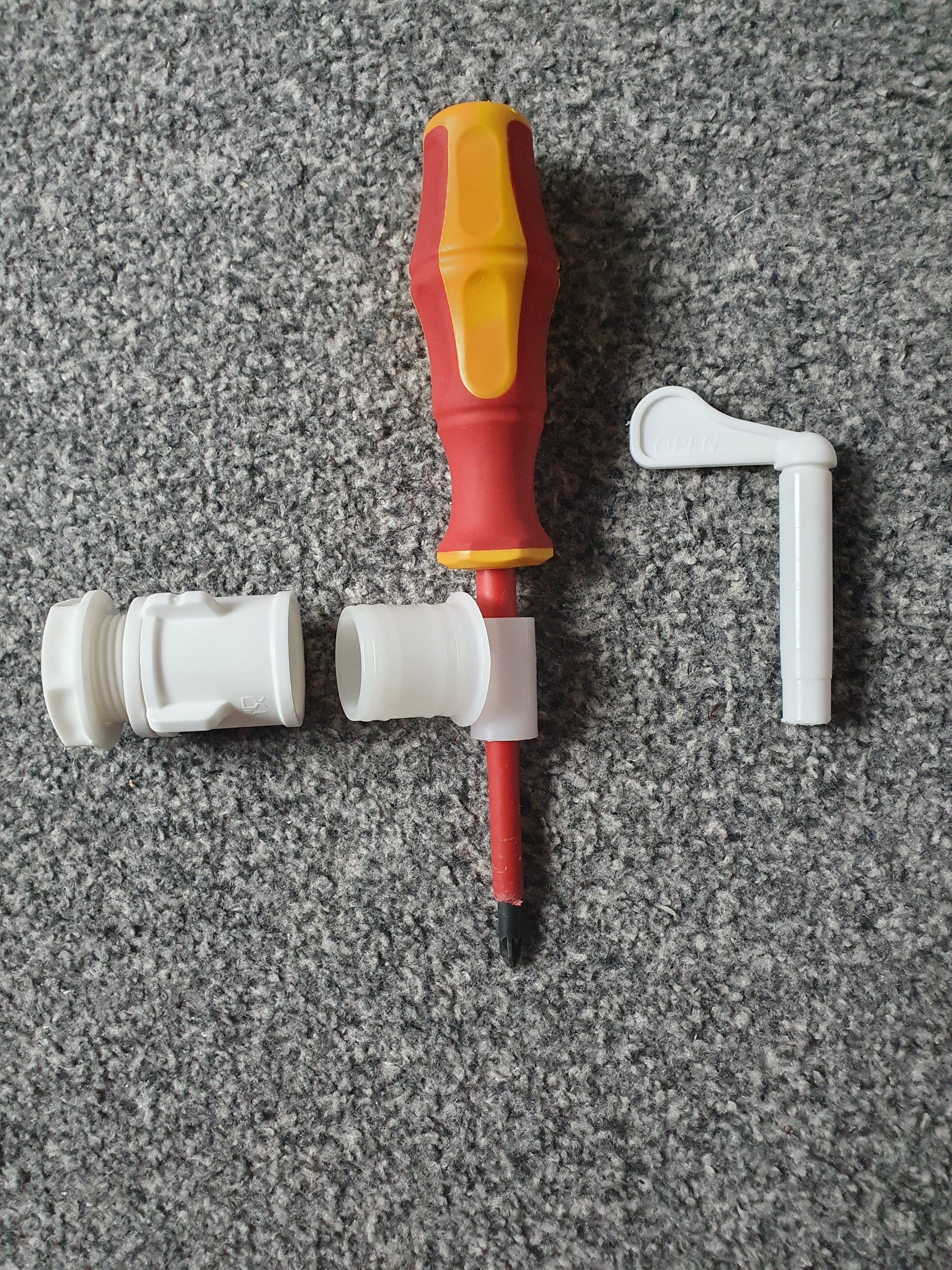

These were already fermenting before you helped me to discovered spigot problem.

Ah, I see.

Only tubing i have is autosiphon tube that gets cleaned like described.

Inspect and

separately clean and sanitize that hose that's connected to the siphon tube.

Then let the inside dry in between uses. I therefore drape my hoses over a corner pole on a storage rack, so they can drip out from both ends, and air dry over a few days.

Or store (flexible) hoses in the bottom of a bucket containing 5-8 cm (2-3") height of Starsan working solution. Nothing can grow in there, but the vinyl tubing will get a milky/cloudy appearance, which doesn't harm performance. Rinse/brush, then resanitize immediately before using again.

For example:

I have a 2.5' (~75 cm) piece of thin (~5/32" (ID) hose in the bottom of my Starsan bucket. It's being used to take

suck siphon samples from bucket fermenters, through the airlock hole. It's minimally invasive, and none of my brew buckets have spigots to keep clean or get stepped on.

A long

draw brush can be helpful to clean the inside of hoses. Or make one yourself with a wad made of fabric and a piece of wire or nylon string on each end, so you can pull the fabric wad back and forth inside the tubing/hose.

Right before use, or re-connecting to other (cleaned and sanitized) equipment, always re-sanitize the various pieces

again.

Although it's good to pump cleaner, rinse water, then sanitizer through the siphon, it's also crucial to take the individual pieces apart to clean/rinse/sanitize, and... let thoroughly air dry between uses. It's those tight damp spaces where bugs can hide and multiply.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)