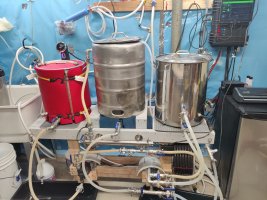

is there a problem with all the heat and igloo coolers close by? been brewing for a few years just now building a permanent brew stand. (Unistrut)I just did a major upgrade to my system. RIMS tube. Stainless Counterflow chiller. A pump. And push button igniters for the burners. Plus new camlocks for the tubing, and a new flow through thermometer. I also added another port to the brew kettle for whirlpooling.

The wet test will be done this week, and if it all checks out, I’ll be brewing on it next week.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your sculpture or brew rig

- Thread starter Onescalerguy

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

There won't be enough heat hitting the mash tun to hurt but it should help to keep the mash temp where it should be.is there a problem with all the heat and igloo coolers close by? been brewing for a few years just now building a permanent brew stand. (Unistrut)

FillWholeWell

Member

- Joined

- May 23, 2021

- Messages

- 16

- Reaction score

- 49

Klarstein Maischfest, built a simple table at perfect height using the frame from a barstool !

The cooler did get hot being so close to the top burner, but I had a sheet of aluminum diamond plate that I made a shield with. The bottom burner isn't an issue, though I did put some diamond plate on the wood stand too. I've been brewing on it since 2010. I haven't burned it down yet.is there a problem with all the heat and igloo coolers close by? been brewing for a few years just now building a permanent brew stand. (Unistrut)

Thanks for the replies... ni e to know I can use my cooler, now to find a cheap source of diamond plate for the new single tier brew stand I have started.The cooler did get hot being so close to the top burner, but I had a sheet of aluminum diamond plate that I made a shield with. The bottom burner isn't an issue, though I did put some diamond plate on the wood stand too. I've been brewing on it since 2010. I haven't burned it down yet.

I’ve melted a cooler before. I use a 3 tier and I just spin the cooler if it gets too hot. I just added a second deflector plate. Looks kind of like a heat sink. I’m an exterior brewer so the cooler MT is my best option.

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$33.98

DYKWSWYX Heavy Duty Brewing Gloves (1 Pair) - 55CM Long Chemical Resistant Plastic Gloves for Beer & Wine Making, Cleaning, Homebrew Equipment Protection

wuhanshijiayangzhiyimaoyiyouxiangongsi

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

Thanks I was pretty sure you could melt a cooler maybe I should add a tier just to protect the cooler. I will still use the pumps I so I can run the wort through my herms coil in my HLTI’ve melted a cooler before. I use a 3 tier and I just spin the cooler if it gets too hot. I just added a second deflector plate. Looks kind of like a heat sink. I’m an exterior brewer so the cooler MT is my best option.

I run a HERMS as well. Adding the heat shield was my ticket. The 20 tip jet burners put out a ton of heat. My rig is hooked up to NG, glad no propane tanks. If I had it to do over, I’d build a 2 tier. I built the structure before I had my pumps.Thanks I was pretty sure you could melt a cooler maybe I should add a tier just to protect the cooler. I will still use the pumps I so I can run the wort through my herms coil in my HLT

martyjhuebs

Naked Gnome Brew Co

Orval

Well-Known Member

- Joined

- Apr 3, 2021

- Messages

- 94

- Reaction score

- 35

My BIAB set up in my basement. Using an SS Brewtech Brew Cube with a mounting plate I made for my pump and chiller.

My BIAB set up in my basement. Using an SS Brewtech Brew Cube with a mounting plate I made for my pump and chiller.

Finally someone picked up on the small wheeled all in one format ! Mine stores in our pantry. I can go from stored to heating mash water in 10 minutes.

I much prefer to put my chiller in the sink.

What are you using to old the heat band on your fermenter ?

Attachments

Last edited:

Finally someone picked up on the small wheeled all in one format ! Mine stores in our pantry. I can go from stored to heating mash water in 10 minutes.

I much prefer to put my chiller in the sink.

What are you using to old the heat band on your fermenter ?

I'm using these when I picked them up on sale. I don't think they're available from Tekton anymore though.

https://www.tekton.com/30-inch-red-adjustable-polyurethane-bungee-cord-62039a1

Throttle79

Cache Creek Brewing

BeerGeekInFL

Well-Known Member

- Joined

- Mar 23, 2021

- Messages

- 282

- Reaction score

- 61

Nothing permanent yet, but I also like that I can just take it all and put it away.

- Joined

- Dec 25, 2021

- Messages

- 86

- Reaction score

- 52

Just picked this up. Still need some fittings and hoses as well as a gas line run to the garage.

- Joined

- Jan 3, 2020

- Messages

- 3,215

- Reaction score

- 3,893

Nice wheels!Just picked this up. Still need some fittings and hoses as well as a gas line run to the garage.

View attachment 763877

Shes almost complete!

I can see a " Tom's Brew Shop" sticker behind that thermometer on the MT.

One kettle is 240V electric for boils and/or BIAB. When I direct-fire the other kettle for a mash I just roll this away from the wall and the propane burner lifts the MT up enough to directly drain into the BK. The FRP panel behind the cart and sink turned out to be a great idea to protect the wall. The cart was a CraigsList find several years back and I just shortened the legs with a hacksaw. It was a rolling food prep cart about 36” high from a putt putt center snack bar

Cameronl

Well-Known Member

- Joined

- Mar 10, 2021

- Messages

- 233

- Reaction score

- 730

Here's my new e-herms setup. I still need to put some finishing touches on it. It needs a new cart top (have you price plywood lately?!?) Right now it's made of scraps I have lying around. The propane burner is leftover from my previous setup. It has since been removed. I had a bunch of insulating bubble wrap from Hello Fresh deliveries, so what the heck, I wrapped some around the mash tun.

I'm particularly pleased with the control cart I came up with. I wanted one unit that included the pumps and plate chiller that I can easily roll into the basement for the winter. I have to brew outside, and after destroying some garden hose attachments after a big freeze, I'm paranoid about leaving anything that might have water in it.

The plate chiller is on a hinge so I can tip it up to drain it. I also upgraded the dial on the BK's SSVR with a better quality knob and created an indicator dial from this website. I messed around with the inner diameter to fit the knob, laser printed on some cardstock, stuck it to some hardboard with spray adhesive, cut it out and sealed with a few coats of spray lacquer.

I'm particularly pleased with the control cart I came up with. I wanted one unit that included the pumps and plate chiller that I can easily roll into the basement for the winter. I have to brew outside, and after destroying some garden hose attachments after a big freeze, I'm paranoid about leaving anything that might have water in it.

The plate chiller is on a hinge so I can tip it up to drain it. I also upgraded the dial on the BK's SSVR with a better quality knob and created an indicator dial from this website. I messed around with the inner diameter to fit the knob, laser printed on some cardstock, stuck it to some hardboard with spray adhesive, cut it out and sealed with a few coats of spray lacquer.

Attachments

I got tired of only being able to brew in the warmer months in the garage, so I built an electric system in my basement. Well, I bought the control box and the vessels.

Introducing, The Copper Hood Brewpub:

Introducing, The Copper Hood Brewpub:

Here’s my brew table shown while sparging a batch of Raging Irish Red Ale:

The table is built on a restaurant equipment stand:

https://www.webstaurantstore.com/equip-stand-24x72-galv/600ES2472G.html

I attached a 6’ section of Unistrut horizontally to the front of the table to mount the pumps and home made valve manifold. There is a second section of vertical Unistrut on the right to mount the counterflow chiller. Not very visible is a Gladiator GearTrack rack mounted on the left side for hose and cord storage when the brew table isn’t in use and is rolled back against the garage wall.

The valve manifold, vertical Unistrut and GearTrak are all attached using custom 3D printed brackets.

Note: the digital thermometer in the thermowell of the mash tun is wildly inaccurate (reads way, way low). I need to calibrate it.

The table is built on a restaurant equipment stand:

https://www.webstaurantstore.com/equip-stand-24x72-galv/600ES2472G.html

I attached a 6’ section of Unistrut horizontally to the front of the table to mount the pumps and home made valve manifold. There is a second section of vertical Unistrut on the right to mount the counterflow chiller. Not very visible is a Gladiator GearTrack rack mounted on the left side for hose and cord storage when the brew table isn’t in use and is rolled back against the garage wall.

The valve manifold, vertical Unistrut and GearTrak are all attached using custom 3D printed brackets.

Note: the digital thermometer in the thermowell of the mash tun is wildly inaccurate (reads way, way low). I need to calibrate it.

My rig is a  I really love to look at these systems. I would love to be an inside brewer. I’ll tell my 3864 this weekend it’s riding in a Maybach on the way to the chamber! Love it!

I really love to look at these systems. I would love to be an inside brewer. I’ll tell my 3864 this weekend it’s riding in a Maybach on the way to the chamber! Love it!

razzman

Well-Known Member

Love the timer!Here’s my brew table shown while sparging a batch of Raging Irish Red Ale:

View attachment 846787

The table is built on a restaurant equipment stand:

https://www.webstaurantstore.com/equip-stand-24x72-galv/600ES2472G.html

I attached a 6’ section of Unistrut horizontally to the front of the table to mount the pumps and home made valve manifold. There is a second section of vertical Unistrut on the right to mount the counterflow chiller. Not very visible is a Gladiator GearTrack rack mounted on the left side for hose and cord storage when the brew table isn’t in use and is rolled back against the garage wall.

The valve manifold, vertical Unistrut and GearTrak are all attached using custom 3D printed brackets.

View attachment 846794

View attachment 846796

Note: the digital thermometer in the thermowell of the mash tun is wildly inaccurate (reads way, way low). I need to calibrate it.

stamandster

undefined member

stamandster

undefined member

Yikes!

You'll never have to worry about someone stealing that rig and actually brewing beer - unless it comes with the operating instructions...

Cheers!

You'll never have to worry about someone stealing that rig and actually brewing beer - unless it comes with the operating instructions...

Cheers!

stamandster

undefined member

That's the planYikes!

You'll never have to worry about someone stealing that rig and actually brewing beer - unless it comes with the operating instructions...

Cheers!

4 years into the hobby,started brewing extract out side,2 years into it,went to

all grain moved to a brewzilla Gen. 3.3, I fitted it with a steam condenser, powered by a 12 volt pump that recirculates cold water (bottom cooler on the rack), a pressre regulator and accumulater( bladder) keep a steady stream at 15psi in the condenser.

I fitted the brewzilla with a glass sight glass off of the drain tap, after replacing several polycarbonate ones,the sight glass allows me to be sure to not have a dry boiler during recirculating during my mash in, by watching the level, I can adjust the pump flow for max volume over the grain without triggering the dry boiler sensor.

Sparge water is in the 10 gallon cooler on the right of the Brewzilla, it is fitted with a 1k watt heating element controled by an ink bird controller, a, I pre heat this the night before, and it will hold temp at 140 from 170 over night, so it only takes a few minutes to bring it to optimum sparge temp,a small pump supplies water for the sparge.

I use a 30 gallon rubbermaid trash can hooked to an aquarium chiller set to 40 degrees to pump cold(recirculated) water to.my SS induction coil to cool my wort.

In the back ground, above the slop sink( with hot and cold water) is a RODI system I use to.make up.my brew water. An overhead double pulley system allows me to put the malt tube for sparging.

all grain moved to a brewzilla Gen. 3.3, I fitted it with a steam condenser, powered by a 12 volt pump that recirculates cold water (bottom cooler on the rack), a pressre regulator and accumulater( bladder) keep a steady stream at 15psi in the condenser.

I fitted the brewzilla with a glass sight glass off of the drain tap, after replacing several polycarbonate ones,the sight glass allows me to be sure to not have a dry boiler during recirculating during my mash in, by watching the level, I can adjust the pump flow for max volume over the grain without triggering the dry boiler sensor.

Sparge water is in the 10 gallon cooler on the right of the Brewzilla, it is fitted with a 1k watt heating element controled by an ink bird controller, a, I pre heat this the night before, and it will hold temp at 140 from 170 over night, so it only takes a few minutes to bring it to optimum sparge temp,a small pump supplies water for the sparge.

I use a 30 gallon rubbermaid trash can hooked to an aquarium chiller set to 40 degrees to pump cold(recirculated) water to.my SS induction coil to cool my wort.

In the back ground, above the slop sink( with hot and cold water) is a RODI system I use to.make up.my brew water. An overhead double pulley system allows me to put the malt tube for sparging.

Attachments

How much water do you recirculates? And how hot does it get by the end, and does this affect the efficiency of the steam condenser? Been wondering if you could have a closed loop system but thought you'd need some way to get at least some sort of heat exchange to get some of the heat out of the system.I fitted it with a steam condenser, powered by a 12 volt pump that recirculates cold water (bottom cooler on the rack), a pressre regulator and accumulater( bladder) keep a steady stream at 15psi in the condenser.

I start with a cooler of cold water, I freeze 2 coffee cans of water ahead of time so I have 2 blocks of ice as well and put it in the cooler by the end of the boil, it still is about 50 degrees or so(cold to the touch)..without the ice, the water gets pretty warm, the manufacturer suggests using a garden hose/faucet, even though its regulated under 30psi, that would be alot of water down the drain, my system works well, it's not perfect, but no windows are steamed up and nothing surrounding the pot is sticky, that wasnt the case before the steam trap.. like any of this, there is a learning curve, it took a few brew sessions to dial it in.How much water do you recirculates? And how hot does it get by the end, and does this affect the efficiency of the steam condenser? Been wondering if you could have a closed loop system but thought you'd need some way to get at least some sort of heat exchange to get some of the heat out of the system.

Similar threads

- Replies

- 11

- Views

- 1K

- Replies

- 130

- Views

- 5K

- Replies

- 45

- Views

- 3K