// BrewBros script

// v1.0 9/16/2019

// Matias G.

[device setup] // setup elements with base values, disable loops, reset buttons and timers.

"System Status" Value = "Setting up devices"

//variables

new bool StartBrew

new bool StartStrike

new bool StartMash

new bool StartMashOut

new bool StartSparge

new bool StartBoil

new bool StartWhirlpool

new bool StartChill

new bool StartRack

StartBrew = False

StartStrike = False

StartMash = False

StartMashOut = False

StartSparge = False

StartBoil = False

StartWhirlpool = False

StartChill = False

StartRack = False

//elements and devices

"BK PID" Enabled = False //disable PID to prevent output

"HLT PID" Enabled = False //disable PID to prevent output

"BK Element Select" State = False

"HLT Element Select" State = False

"Water Pump" State = False

"Wort Pump" State = False

"Strike" Visibility = Hidden

"Mash" Visibility = Hidden

"MashOut" Visibility = Hidden

"Sparge" Visibility = Hidden

"Boil" Visibility = Hidden

"Whirlpool" Visibility = Hidden

"Chill" Visibility = Hidden

"Rack" Visibility = Hidden

"Step Time Alarm" Active = False

//temps

"Mash In Temp" Value = 155.0 //ballpark for mash in

"Mash Out Temp" Value = 168.0 //ballpark for mash out

//timers

reset "Step Timer"

stop "Step Timer"

//buttons

"Brew Start Btn" State = False

"Brew Start Btn" Visibility = Visible

"Strike OK Btn" State = False

"Strike OK Btn" Visibility = Hidden

"Mash Start Btn" State = False

"Mash Start Btn" Visibility = Hidden

"Sparge OK Btn" State = False

"Sparge OK Btn" Visibility = Hidden

"Boil OK Btn" State = False

"Boil OK Btn" Visibility = Hidden

"Hotbreak Btn" State = False

"Hotbreak Btn" Visibility = Hidden

"Whirlpool Btn" State = False

"Whirlpool Btn" Visibility = Hidden

"Chill OK Btn" State = False

"Chill OK Btn" Visibility = Hidden

"Rack Btn" State = False

"Rack Btn" Visibility = Hidden

"End Brew" State = False

"End Brew" Visibility = Hidden

"Done" State = False

"Done" Visibility = Hidden

"Acknowledge" Visibility = Hidden

sleep 1000

[varible def]

new value MashTemp

new time StepTime

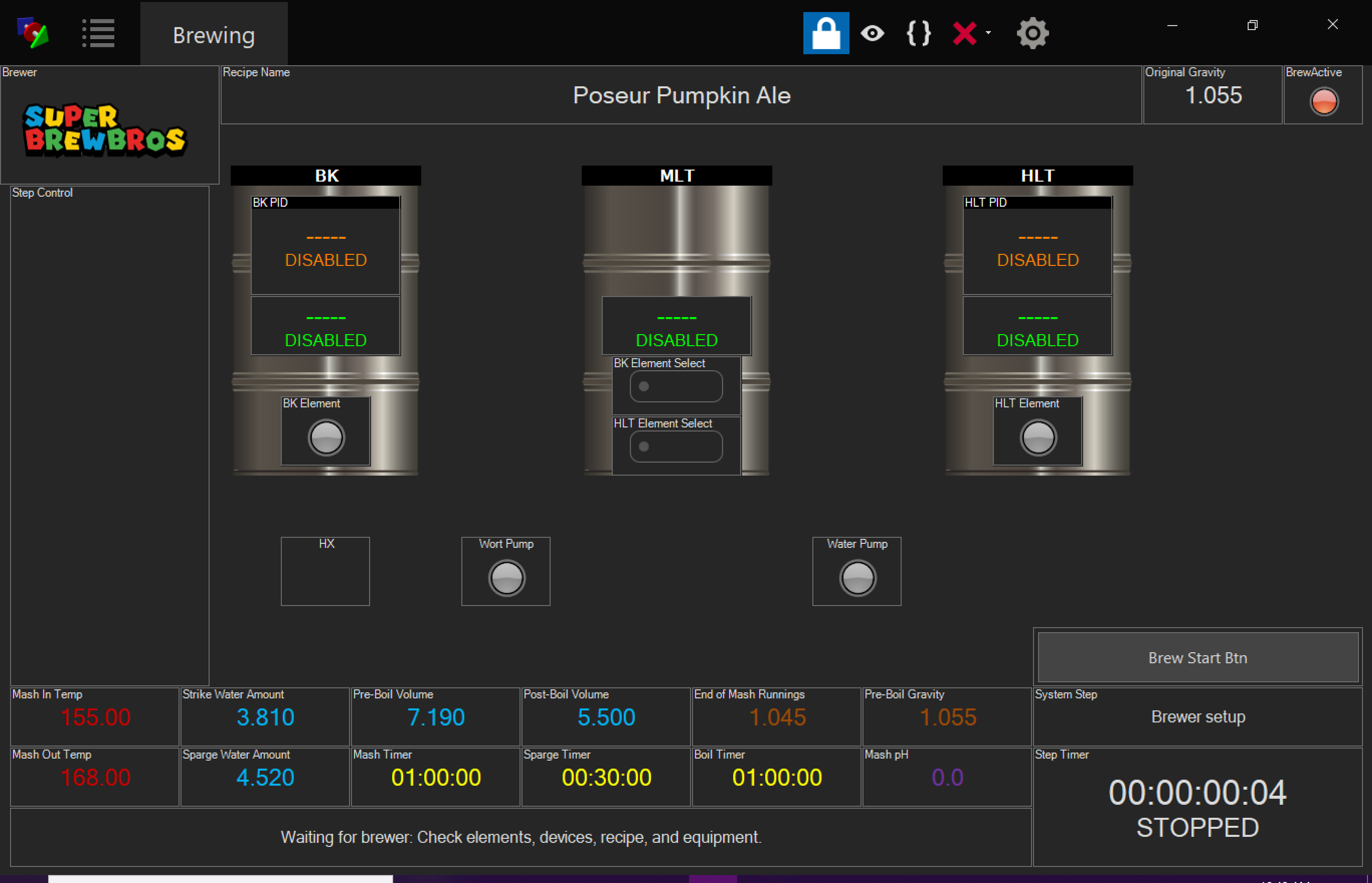

[user setup] //wait for brewer to setup recipe, devices, and equipment

"System Status" Value = "Waiting for brewer: Check elements, devices, recipe, and equipment."

"System Step" Value = "Brewer setup"

wait "Brew Start Btn" state == true //wait for button press that Brewer is ready

if "Brew Start Btn" state == true

"System Status" Value = "BEER TIME!"

"Brew Start Btn" Visibility = Hidden

"Strike OK Btn" Visibility = Visible

StartBrew = True

"Strike" Visibility = Visible

sleep 1000

goto "strike water"

endif

goto "user setup"

[strike water]//add sparge water to MLT and strike water to MLT

new string strikestatus

strikestatus = "Add " + "Strike Water Amount" Value

strikestatus += " gallons of water to MLT and "

strikestatus += "Sparge Water Amount" Value

strikestatus += " gallons of water to HLT."

"System Status" Value = strikestatus

"System Step" Value = "Fill vessels with water"

wait "Strike OK Btn" state == true //wait for button press that Brewer is ready

if "Strike OK Btn" state == true

goto "heat strike"

endif

goto "user setup"

[heat strike]//heat strike and sparge water to strike temp, allow 5 min for mix

new string hs1status

hs1status = "Heat strike water to " + "Mash In Temp" Value

hs1status += " °F."

"System Status" Value = hs1status

StartStrike = True

"HLT PID" Enabled = True

"HLT PID" target = "Mash In Temp" value

"Water Pump" State = True

"Wort Pump" State = True

"HLT Element Select" State = True

"Strike OK Btn" Visibility = Hidden

"System Step" Value = "Heating strike water"

[hs1]

if "HLT PV" Value <= "Mash In Temp" Value

sleep 1000

goto "hs1"

else

sleep 1000

"Step Timer" Value = 00:00:05:00

start "Step Timer"

goto "hs2"

endif

new string hs2status

hs2status = "Strike water is at " + "HLT PV" Value

hs2status += " °F. Waiting 5 min to stabilize."

"System Status" Value = hs2status

sleep 1000

[hs2]

if "Step Time Alarm" Active == true

"Acknowledge" Visibility = Visible

stop "Step Timer"

goto "mash in"

else

goto "hs2"

[mash in]//prep setup and stir grains

"System Status" Value = "Add grains to MLT and mix."

"System Step" Value = "Mashing in"

"Mash Start Btn" Visibility = Visible

StartStrike = False

wait "Mash Start Btn" state == true //wait for button press that Brewer is ready

if "Mash Start Btn" state == true

"System Status" Value = "OATMEAL TIME!"

sleep 1000

goto "mash"

endif

goto "mash in"

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)