Tonight's update is about an extraordinary opportunity I had today, to sit at the foot of the throne at Casa

@BrunDog for an early morning brew. I'm going to cover some of the notes I took.

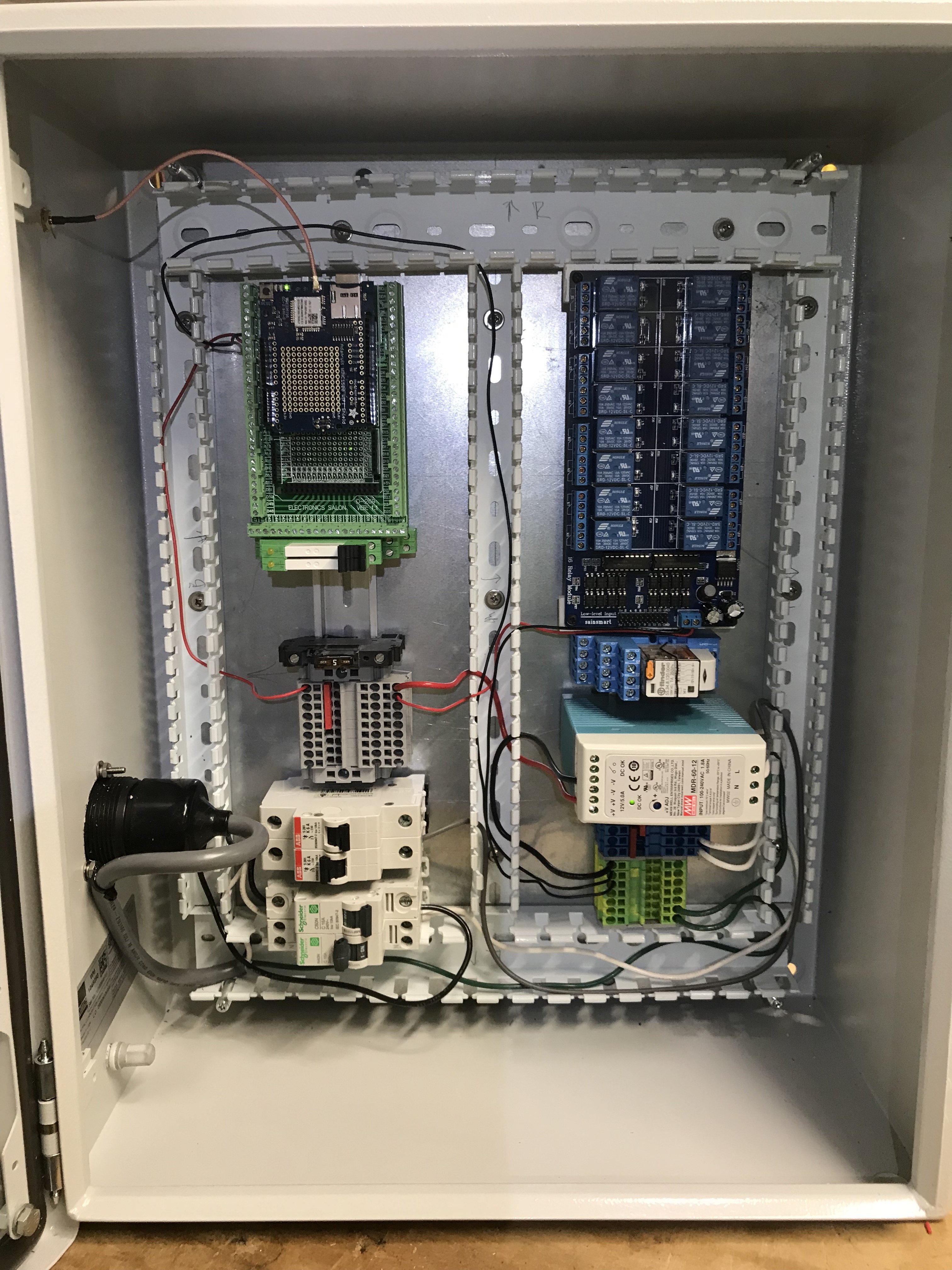

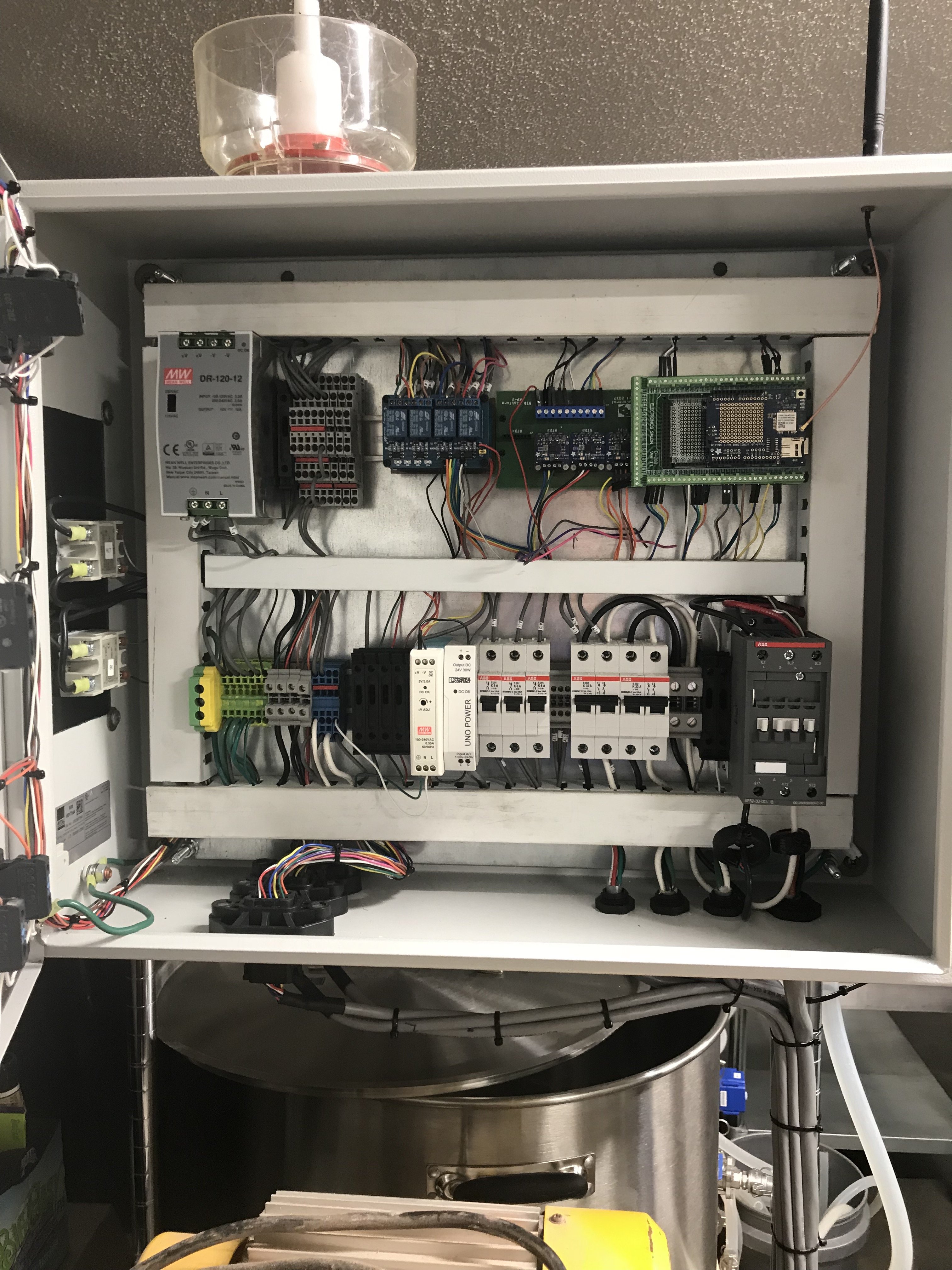

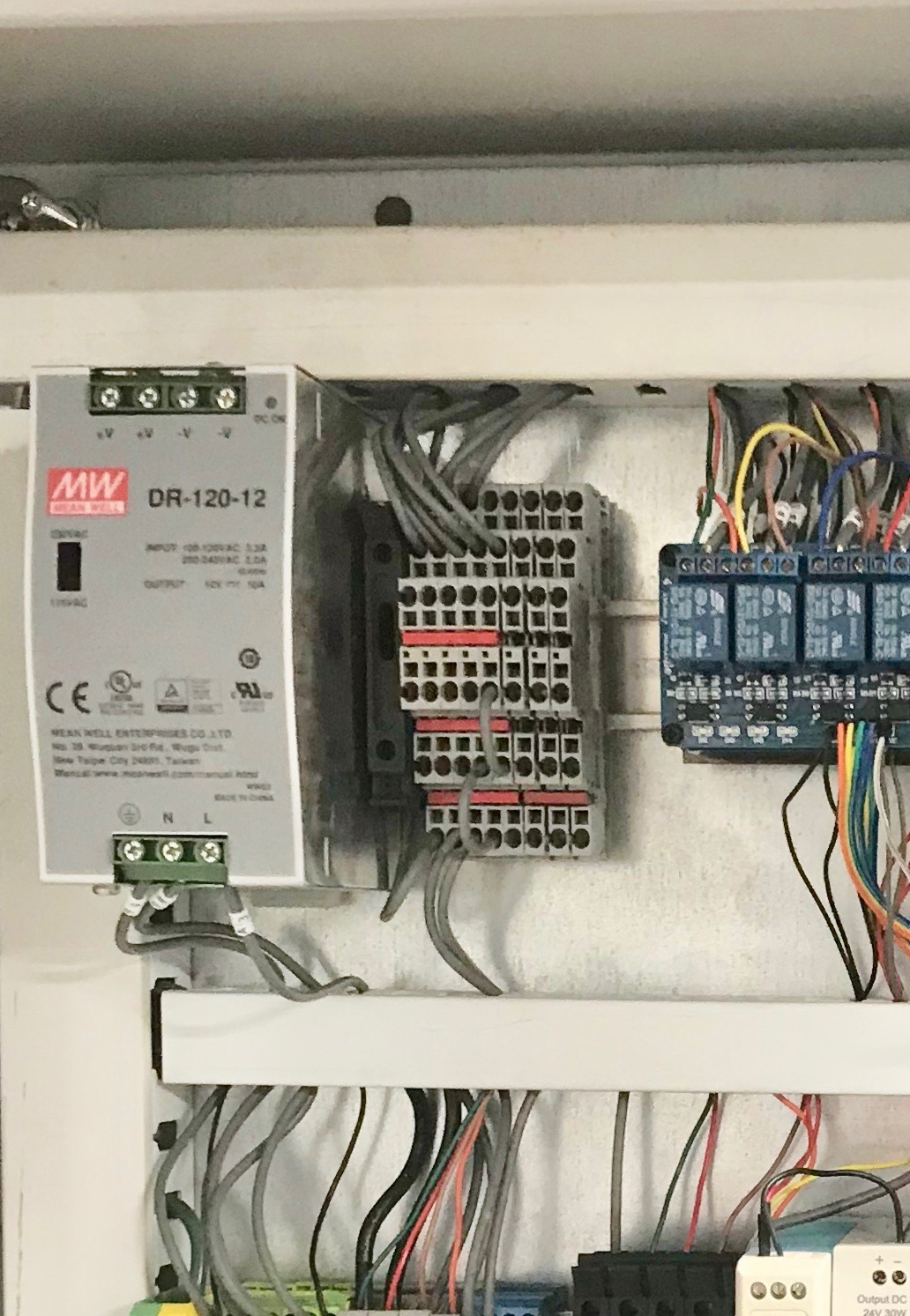

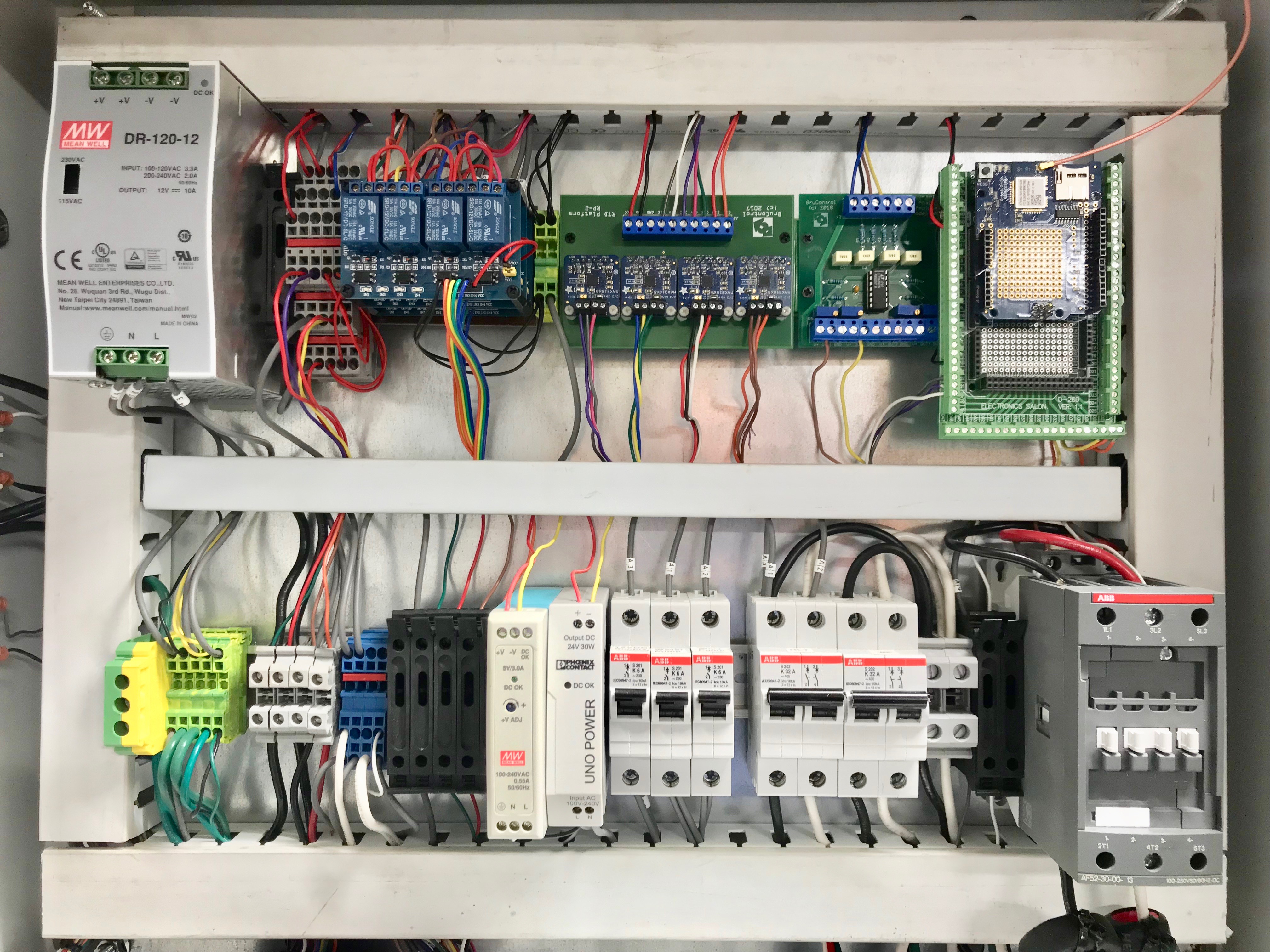

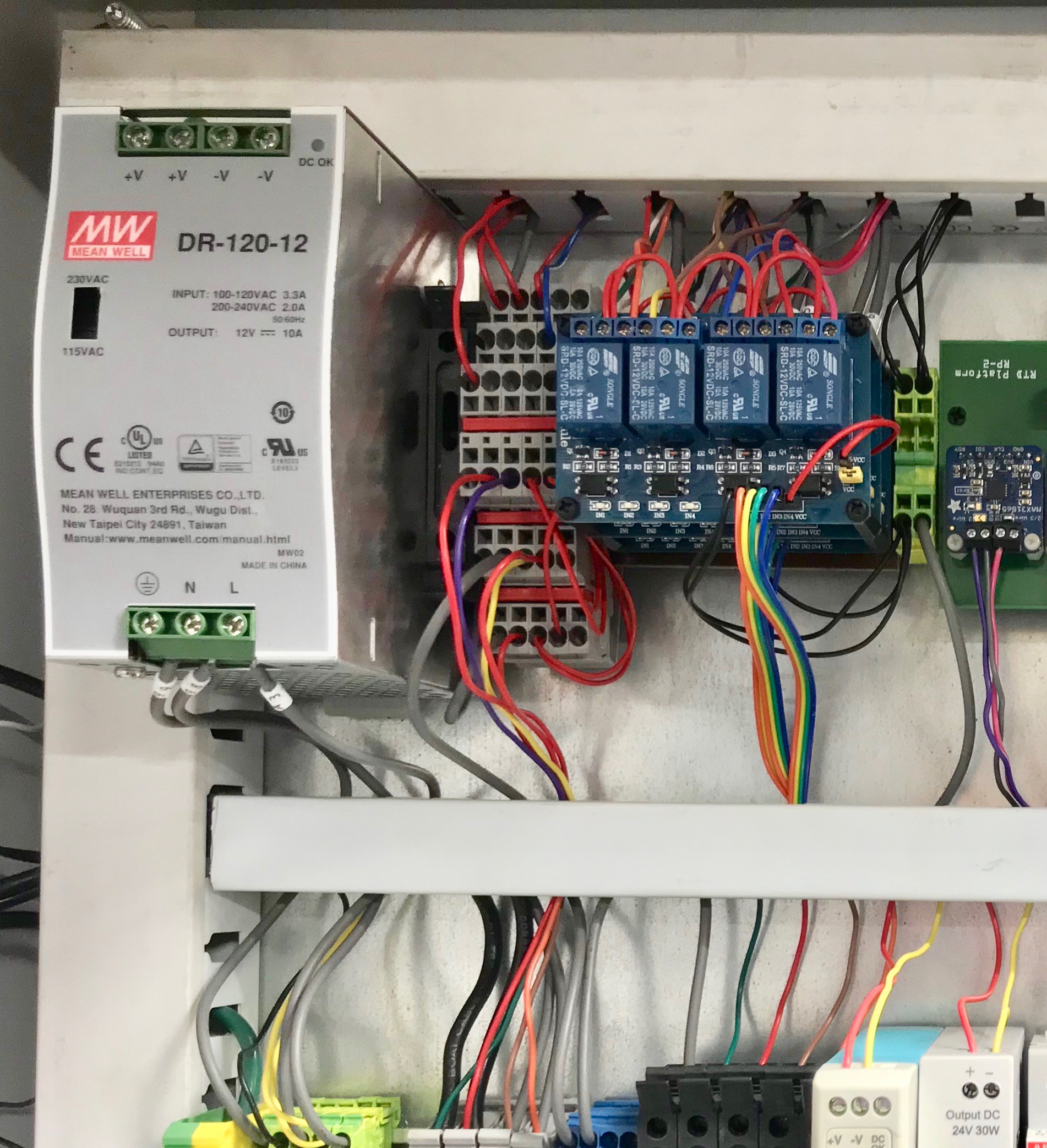

To start with, some hardware context is probably important:

@BrunDog's rig is different than mine, in that he's using a 2-vessel RIMS setup, while I opted for a 3-vessel HERMS rig. The difference? At the end of the day, the water jugs he fills and heaves to the top of the brewstand rack are (in essence) a Cold Liquor Tank, but his RIMS rig certainly appears to shorten the ramp times over what I've measured on my rig. It's hard to tell how much of that is due to batch size difference vs. the RIMS/HERMS debate. My takeaway is that I'll bet I'd be happier if I had a 5500W RIMS tube that I could use as valve-selectable booster heat for either the HLT or the boil kettle. I came away convinced that a 30-gallon kettle is at the upper limit of the capability of a single 5500W element. For efficient multi-batch brew days, my ideal configuration would probably be a 100A panel with a 5500W immersed element and a 5500W RIMS tube for both the HLT and BK. If I were to do that, I would definitely offload the heavy power components to a separate enclosure.

Aonther feature of

@BrunDog's rig that I intend to implement as soon as possible is his fresh water manifold. Between filling kettles, rinsing mash paddles, cooling boiling wort, making a batch of sanitizer, and a hundred other uses, having a single hookup to a garden hose makes the brew day several orders of magnitude simpler. A self-coiling hose attached to the brew stand, an inlet to the cleanup cycle, a driveway washdown hose, and (with filtration) a pot-filling supply all take away a tedious list of manual steps to get to the right kind of water needed on brew day.

While I don't see it on my radar in current planning,

@BrunDog has invented (and already had shamelessly knocked off) a very nice steam condenser that allows a full boil cycle with the kettle lid firmly seated, with nothing but a trickle of waste water to show for it. He's got a separate thread on it,

Here. I saw it in action today, and it works very well. It's one of the consumers off of his garden hose manifold, and it doesn't seem to affect pressure or flow for any of the other draws off of the manifold.

The last hardware that I'd like to review is his two-stage wort chiller. With little fuss, no muss, and two 10-lb. bags of ice, I saw a batch of wort come out of a boil kettle at 170+ and go into a fermenter at 65℉. That's no small feat, given the tap water was coming out of the hose at 85℉+. The trick is to use the garden hose water to accomplish the first stage of cooling to 85℉ or so, and then route the semi-chilled wort through an icy-cold loop with some temperature sensing and flow control, so that the final output into the fermenter is at a precise, controlled pitching temperature.

All in all, the rig seemed very well-organized, and was obviously dialed in and useful. It was nice to pick up some pointers and hacks, as I'm just getting organized with my new rig. What was eye-popping was what he'd done with the app. Understandable, since it's his app, but eye-popping nonetheless. I spent the trip home with the dawning realization that the only fundamental difference between

@BrunDog's implementation and mine was the use of scripts. But oh, what a difference!

First off:

@BrunDog created a separate Workspace where the recipe-specific parameters get entered. Water volumes, mash steps, mash temps, sparge volumes, hop addition timing, etc., etc. Everything came off of a Beersmith printout, and was set up to be entered in the same sequence as it appeared in the printout. The underpinnings of that capability are based on a script where all of the recipe-specific stuff is a defined variable.

The script doesn't have to be edited for each recipe. In his case, everything from strike volume through pitch temperature is a variable that gets plugged in before the first valve opens. I got busy with my own system as soon as I got home, while it was fresh in my mind.

Here's what I have so far:

The second thing that was really cool was the separate scripts for rinsing and cleaning the rig. He's got his system set so that the rinsing script that runs at the beginning and at the end of the cleanup process is open loop (hose water comes into the process and goes down the driveway), but the hot PBW script cycle that runs in the middle of the process is closed loop, where a fixed amount of soapy water is heated, sprayed, and recirculated. (hardware observation: CIP sprayers are critical).

All in all, it was a really great learning experience. There's nothing like seeing the scripting in action. Hat tip to

@BrunDog for the huge extra mile in customer service.

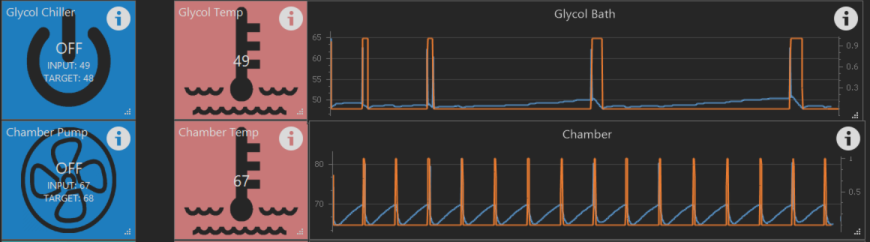

In other news, the new ferm chamber is doing very well. The graphs in the pic below are over a four-hour span. While the middle graph of the fermenter temp may seem a little spikey, a close look at the Y-axis on the left shows the oscillation spanning about 2℉. Not bad for a hot-assed garage in August:

Tomorrow is the end of the diacetyl rest and the start of a ramp-down to lagering temps. That will be the acid test, for sure.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)