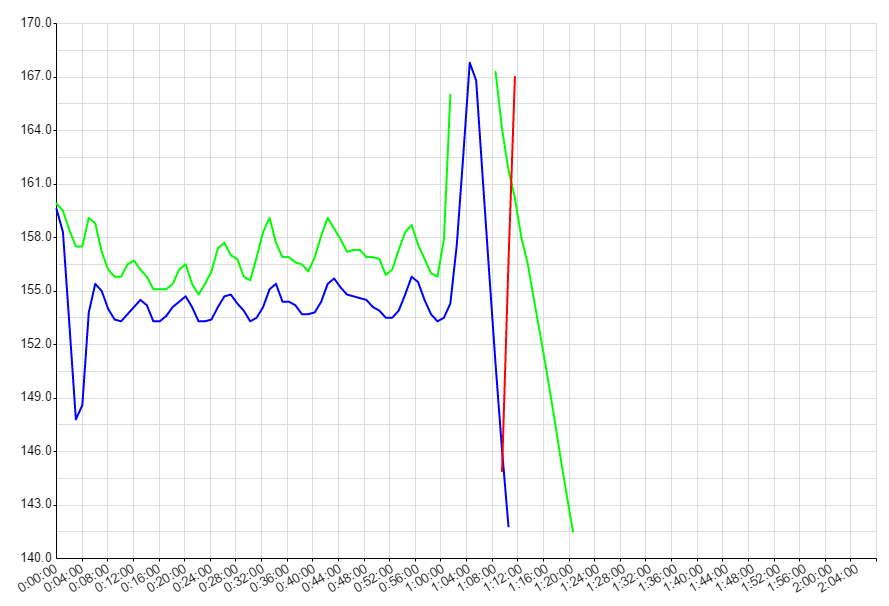

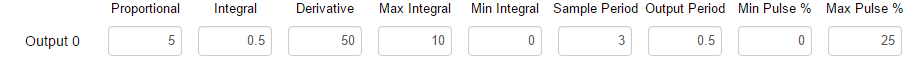

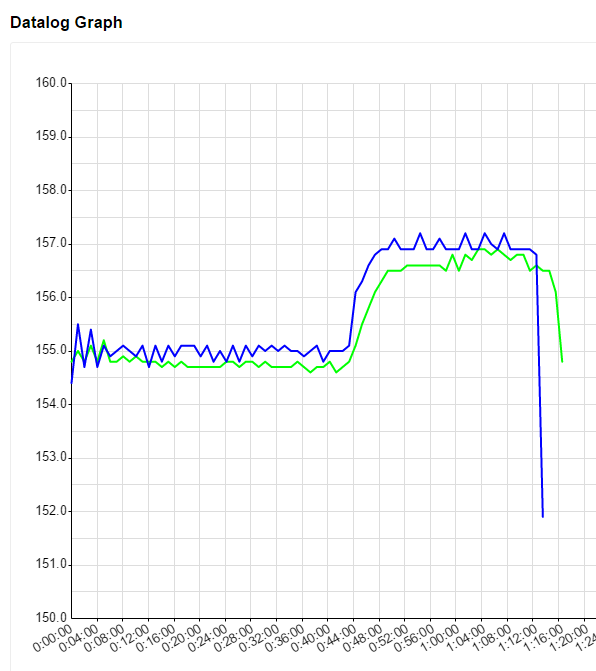

I assume by looking back at your hardware and above, that the green trace is the probe down in the MLT next to the element? And that the blue trace is a probe somewhere on the feed back into the MLT? Which is the probe feeding the PID?

Also, one quick recommendation would be to insulate your MLT. Way too much heat getting lost there given your temps. Also you need to recirc as fast as your false bottom or bag will allow.

Also, one quick recommendation would be to insulate your MLT. Way too much heat getting lost there given your temps. Also you need to recirc as fast as your false bottom or bag will allow.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)