You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BCS 2 Vessel No Sparge Garage Brewery Build

- Thread starter poptarts

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

bayoujeeper

Well-Known Member

Sweet system pop! Do you boil with the lid on for the entire boil?

poptarts

Well-Known Member

Sweet system pop! Do you boil with the lid on for the entire boil?

yea, it is ducted out the wall.

bayoujeeper

Well-Known Member

yea, it is ducted out the wall.

That is what I figured, Do you have any pics of the ducting setup? I breezed back through the thread but I might have missed that.

poptarts

Well-Known Member

That is what I figured, Do you have any pics of the ducting setup? I breezed back through the thread but I might have missed that.

https://www.homebrewtalk.com/showpost.php?p=7344140&postcount=312 should give some better pics, its basically dryer duct and and a 4" inline fan.

Cool video and very slick automatic system!

John

John

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

poptarts

Well-Known Member

bottom fill worked good enough for baltic porter, hit my estimated 65% for the 1.085 beer. My element in my mlt burnt out as I was ramping up to mashout. Not sure what happened but pretty annoying. Ordered 2 new ones that are UL listed, hopefully its a one time deal.

adhd-brouwerke

Member

No problems with dms in the beer? Or do you have strong enough hood?

poptarts

Well-Known Member

new elements showed up, the quality is a decent bit better, they were way less of a PITA to install due to longer threads, so that was a nice touch. They seem to heat up good and what not. In other good news, solved the pump priming issue with a pump prime step XD

dsniegocki

Well-Known Member

I just can't understand why you haven't automated your hop additions.

Seriously, GREAT job not to mention thoroughly enjoyable write-up!

Seriously, GREAT job not to mention thoroughly enjoyable write-up!

poptarts

Well-Known Member

I just can't understand why you haven't automated your hop additions.

Seriously, GREAT job not to mention thoroughly enjoyable write-up!

Still trying to figure out a good design for that honestly. Its definitely on the table as something I want to do with this thing once its nice and stable.

dsniegocki

Well-Known Member

Still trying to figure out a good design for that honestly. Its definitely on the table as something I want to do with this thing once its nice and stable.

If I was ever going to do one, I would start with the idea that the brew-boss uses:

http://www.brew-boss.com/product-p/hb-master.htm

I would think an electrically controlled servo could just rotate a plate x degrees, and the pellets drop right through a hole in the bottom.

poptarts

Well-Known Member

That could work easy, i dig that. I like that they want $200 for that. Pretty sure I can make it for like $25 with something like this. http://www.ebay.com/itm/231595874228?var=530832976161 Could plug in and work off the relay board just like the valves....

Rip off.

Get a 1 rpm motor. Two cake pans, and some drain/gutter pipe and some PVC pipe. Done.

Probably need some threaded rod and some other odds and ends. I did one based on a zymurgy DIY article for a continuous hop addition. Worked like crap, but I still have the motor and the PVC. And the rod. Would probably be easy to implement an output control in BCS to run for 10 seconds, rotate the nested cake pan with PVC tubes mounted and drilled below to dump into a chute. Would need to carefully setup the timing of it all and have the holes all aligned and probably a non-friction washer or something like non stick cake pans so they slide easily. I might build one myself now that I think of it!

Get a 1 rpm motor. Two cake pans, and some drain/gutter pipe and some PVC pipe. Done.

Probably need some threaded rod and some other odds and ends. I did one based on a zymurgy DIY article for a continuous hop addition. Worked like crap, but I still have the motor and the PVC. And the rod. Would probably be easy to implement an output control in BCS to run for 10 seconds, rotate the nested cake pan with PVC tubes mounted and drilled below to dump into a chute. Would need to carefully setup the timing of it all and have the holes all aligned and probably a non-friction washer or something like non stick cake pans so they slide easily. I might build one myself now that I think of it!

poptarts

Well-Known Member

http://www.foodservicewarehouse.com/pinch/trypc-8/p1516137.aspx 66 cents, that should do the trick.

dsniegocki

Well-Known Member

Yeah that $200 is a joke. I like the cake pan idea @TrickyDick. Looking forward to seeing how it fits in to the system.

$8 for S&H. LOL!!

Yeah but those would work. I'm gonna see if I have some scrap stuff lying around I can use. Might be easy to hang it from my ceiling rather than find a mount for it to clip on the side of the kettle. Plus can easier set the drop height so it doesn't interfere with putting lid on, or stirring, etc.

Like I need a new project....

Yeah but those would work. I'm gonna see if I have some scrap stuff lying around I can use. Might be easy to hang it from my ceiling rather than find a mount for it to clip on the side of the kettle. Plus can easier set the drop height so it doesn't interfere with putting lid on, or stirring, etc.

Like I need a new project....

iijakii

Well-Known Member

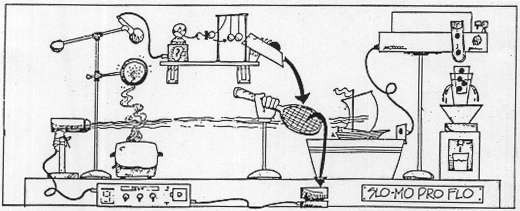

A rotating pan isn't cool enough. You need an elaborate system with marbles and scales.

dsniegocki

Well-Known Member

A rotating pan isn't cool enough. You need an elaborate system with marbles and scales.

...

poptarts

Well-Known Member

[ame]https://www.youtube.com/watch?v=IvUU8joBb1Q[/ame]

BrewingChemist

Well-Known Member

stumbled upon this and wanted to say this was an awesome build. thanks for documenting it so well!

poptarts

Well-Known Member

I will be moving and have to sell this system due to new living space requirements. If you want it, come and get it.

https://www.homebrewtalk.com/showthread.php?p=8102690#post8102690

https://www.homebrewtalk.com/showthread.php?p=8102690#post8102690

Similar threads

- Replies

- 11

- Views

- 969

- Replies

- 11

- Views

- 1K