Ive been slowly working my way through the literature posted by the LODO Team. I havent been able to track down any of the textbooks, but I've been reading up on the articles (Narziss, Bamforth, and others).

I still have much to learn so take what I say with a HUGE grain of salt: for me, the jury is still out on hotside aeration BUT the cold side of the process in MONUMENTALLY IMPORTANT AND DIFFICULT. Any interaction between your beer and the air post fermentation is detrimental to your beer and can take weeks off of its ideal lifespan. Oxidation on the cold side is one thing conclusively proven by food scientists via lab experiments, brewhouse practice, and tasting panels. So purge your vessels as much as possible, spund or carbonate with live active yeast, and get those beers cold asap to reduce your beer's chance of deteriorating too quickly.

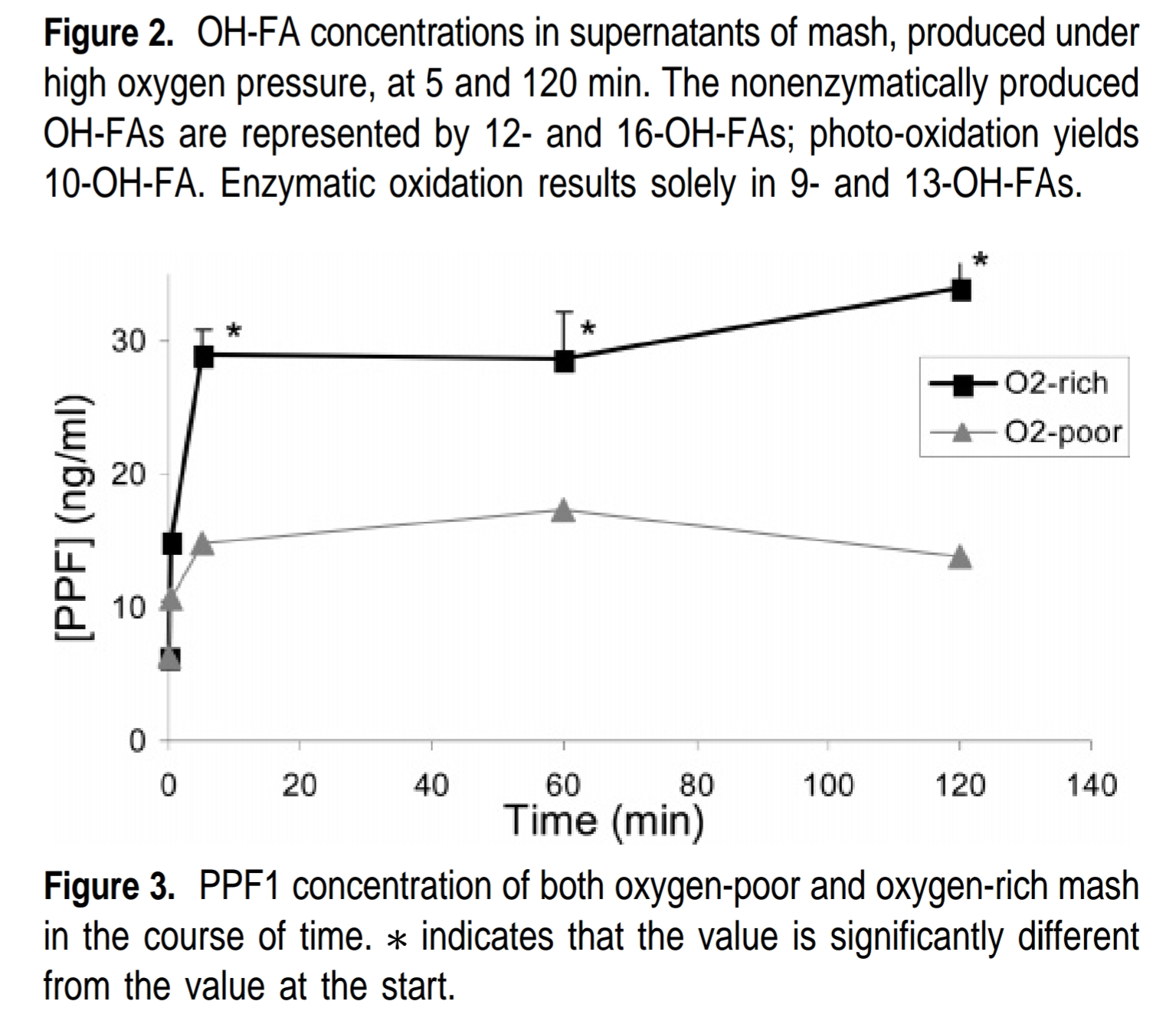

On the hot side, 1 study that compared o2 rich and o2 poor worts for phenolic fatty acids (a precursor to enzymatic oxidation) found that, yes, less o2 in the wort did increase its quality, but the difference was not a stark as one might imagine.

(Oxidative degeneration of lipids during mashing. Mariken, et al.)

The difference between o2 rich and o2 poor worts? One was milled in the presence of pure o2, and mashed with continuous exposure to pure o2.

The o2 poor sample was crushed in the presence of pure argon, and mashed with twice dearated water under pure argon pressure without any o2 exposure. In otherwords, almost impossible standards for a homebrewer, and difficult even for a brewery. *Do bear in mind, of course, this is only one example from one study*

The good news is that much of LODO is just a return to good brewing practice and we should all try to comply (hot break skim, separating trub, light rolling boil). But I am not yet convinced of the "less than 1ppm of DO".

I still have much learning to do still, though.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)