SpikeBrewing

Well-Known Member

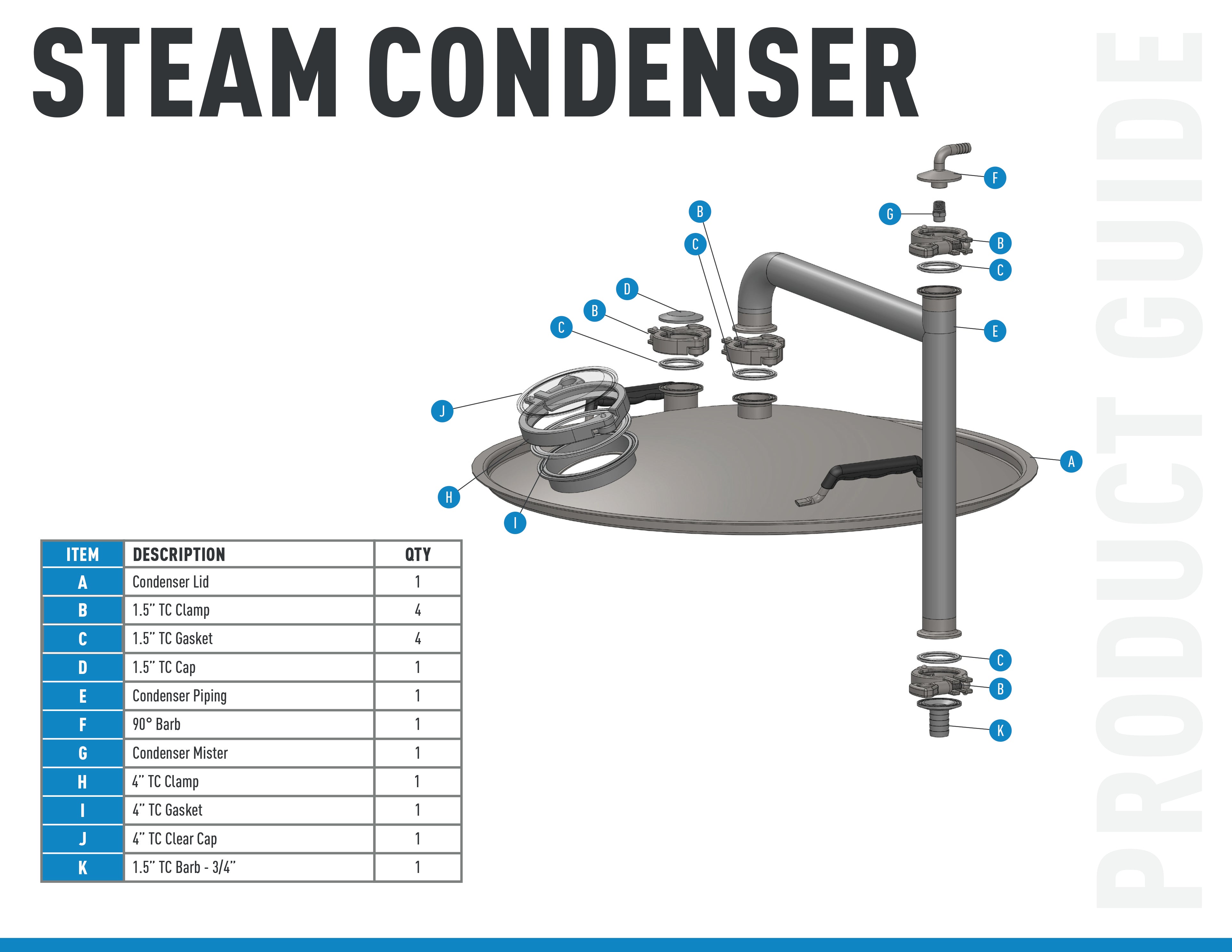

We are extremely excited to announce the upcoming release of our new steam condenser lids! We've had a few people ask what a steam condensing lid is and what the advantages are so we'll talk about them a little more. We hope this thread can spark some discussion around the concept. We're happy to answer questions everyone might have!

What is a steam condensing lid?

A steam condensing lid is a device that can be placed on your kettle during boiling. The lid converts steam produced during the boil back into water using a misting nozzle which is installed in the top piping. The misting nozzle creates a vacuum which effectively draws the steam out of the kettle.

What are the advantages of a steam condensing lid?

The steam condensing lid eliminates the need for an exhaust hood or keeping a garage door open during indoor brewing (usually electric). The steam created during boiling (usually 1-2 gallons) will condense on your walls, in your walls and on your equipment; this lid eliminates that issue. An added benefit is the water used to condense the steam can be captured and used for cleaning as it will be quite hot.

DMS

Dimethyl Sulfide (otherwise known as DMS) is a common off flavor which is boiled off during the boil step. Many brewers have concerns about DMS off flavors when using a steam condensing lid; we did too! That's why we worked with the University of Wisconsin-Milwaukee's chemistry lab to confirm that DMS was still being properly boiled off and not present in the wort. Our testing showed that after just 30 minutes that DMS had been completely removed and below detectable laboratory equipment (25ppb).

Specs:

-Lids for 10, 15, 20, 30 and 50gal Spike kettles

-The lid was designed to work with other popular brands like SS, Blichmann and MegaPot. We will be releasing specific dimensional specs so you can confirm the lid will work with an existing kettle.

-4" port with clear cap to monitor boil and for easy hop additions (without lid removal)

-Additional 1.5" TC port for a CIP ball

Sign up for the steam condenser email list to get first looks/info on pricing, release date, sizing, etc!

What is a steam condensing lid?

A steam condensing lid is a device that can be placed on your kettle during boiling. The lid converts steam produced during the boil back into water using a misting nozzle which is installed in the top piping. The misting nozzle creates a vacuum which effectively draws the steam out of the kettle.

What are the advantages of a steam condensing lid?

The steam condensing lid eliminates the need for an exhaust hood or keeping a garage door open during indoor brewing (usually electric). The steam created during boiling (usually 1-2 gallons) will condense on your walls, in your walls and on your equipment; this lid eliminates that issue. An added benefit is the water used to condense the steam can be captured and used for cleaning as it will be quite hot.

DMS

Dimethyl Sulfide (otherwise known as DMS) is a common off flavor which is boiled off during the boil step. Many brewers have concerns about DMS off flavors when using a steam condensing lid; we did too! That's why we worked with the University of Wisconsin-Milwaukee's chemistry lab to confirm that DMS was still being properly boiled off and not present in the wort. Our testing showed that after just 30 minutes that DMS had been completely removed and below detectable laboratory equipment (25ppb).

Specs:

-Lids for 10, 15, 20, 30 and 50gal Spike kettles

-The lid was designed to work with other popular brands like SS, Blichmann and MegaPot. We will be releasing specific dimensional specs so you can confirm the lid will work with an existing kettle.

-4" port with clear cap to monitor boil and for easy hop additions (without lid removal)

-Additional 1.5" TC port for a CIP ball

Sign up for the steam condenser email list to get first looks/info on pricing, release date, sizing, etc!

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)