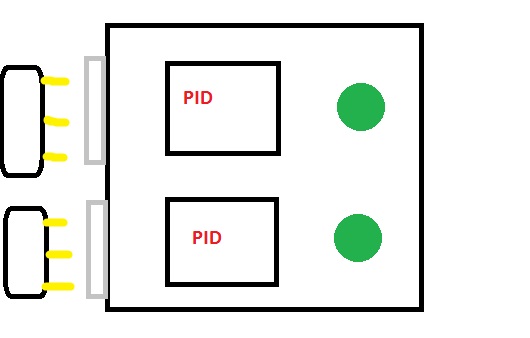

You could use something like this for power control:

http://www.auberins.com/index.php?main_page=product_info&cPath=2_30&products_id=332

http://www.auberins.com/index.php?main_page=product_info&cPath=2_30&products_id=332

It's manual brewing, just like stove-top or propane, I just use electric elements for heat. I don't understand why it can't be this simple...? It has worked well for me for a year now. Again, one guy turns on the stove and watches his thermometer, another fires up the burner and watches his thermometer, I flip two light switches and watch my thermometer. I'm no different than them, just using a different heating source.

Where else are you guys getting your electrical components so I can price it out?

Unless your stove only has an "ON" and "OFF" feature, then it's nowhere near the same. When I brewed on a stove, and then when I upgraded to a dedicated propane burner - both had the option to throttle the amount of heat being applied via the entire range of ON or OFF. Using a switch and an element, your options are just that - ON or OFF. This may work fine for you, but you can't claim there's no difference.

back to the OP, why not go biab? you can get many of the benefits, easier to justify cost, and do it for 1/3 the price or so of a 3 pot system. it's approximate obviously

understood. what is the current system?

one thought, take a look at this http://www.highgravitybrew.com/productcart/pc/Electric-Kettle-Controller-306p3084.htm

all you need then is to install elements in your kettle, run some cable, voila (assuming you have gfci and all of that in place)

Just going to leave this here as the discussion has been touched a few times - http://gnipsel.com/beer/software/calculators/electric-heat.xls

Should help you figure out what size element you need, at a minimum.

-Kevin

I still don't understand how you'll fly sparge single-tier with only one pump. You have to move liquid from HLT to MLT, and simultaneously from MLT to BK. That's two pumps if you fly sparge. Batch sparging, sure, 1 pump. I batch sparge, hit 80% every. single. time.

Hmm I was just going to upgrade my 3 pot setup with a pump, but now all these ideas are making me hesitate about it. I like my setup b/c I hit 70-80% every time. I could use a little more clarification with my beer, sure, but it's still damn good beer. Since RIMS sometimes take a hit with efficiency, maybe I could RIMS, but also batch sparge after to get the last of the sugars out.

i had a very similar setup and while i wasn't concerned about efficiency, my problem was consistency. it was the variability from batch to batch that bothered me. if i always hit 60%, at least i can account for it. however, 65% on one and 80% on another was driving me nuts and was a big motivator for me as well.

a 10% range is pretty big and is a decent reason to change your method.