Love the primers here for the Auber controllers. This would have taken me a lot of trial and error to figure out without the knowledge being shared.

In regards to my build, I am putting the final touches and am not entirely sure what to do about the return.

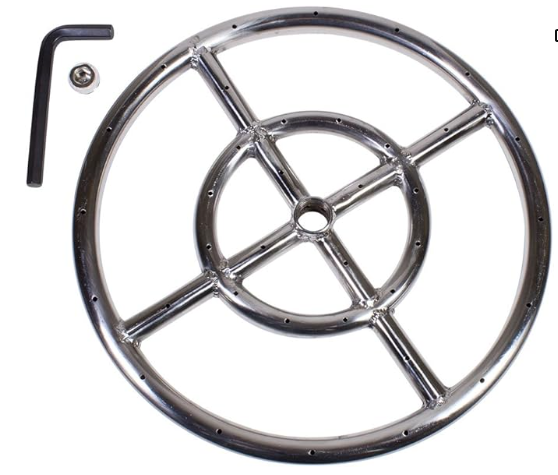

First, a photo:

View attachment 879748

Since the temperature sensor is external and fed through the pickup tube I have to constantly recirculate to keep the temp data up to date. I plan on returning it through the high-mounted spin cycle. My issue is that it dips all the way down to the false bottom, so I'm going to have to cut it down. To replace the whirlpool function I am going to return the wort through the pickup tube at 4:30.

As much as I don't want to cut down the spin cycle, I can't really think of another good return method that doesn't end up stratifying the mash. I'm running a water test right now to make sure the program works.

View attachment 879753

What isn't pictured is my three-way valve that will switch between recirculation and whirlpool. I'll need to get another set of hose barb to TC connectors as I didn't plan for that initially and so I just included a butterfly valve so I can switch it for the test without losing a bunch of water.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)