Fuggledog

New Member

- Joined

- Nov 7, 2021

- Messages

- 4

- Reaction score

- 16

Hello,

Cire recently invited me to the forum and pointed me in the direction of this thread. I'm the bloke in NZ that McMullan (very kindly) sent Harvey's yeast to. I'm very happy to send some on to you DuncB if you'd like to try it too. Is there a way to send a PM on this forum? If so drop me a line and we can work something out (I'm based in Northland).

I recently did a comparison of wort fermented with the Harvey's strain roused vs. 'un-roused'. The results of this simple comparison were far from definitive but may still be of interest (see abridged notes below). My impression currently (based on little experience with the strain), is that rousing is important in encouraging a timely, healthy fermentation and reducing/limiting phenolic character. I don't know if phenols increase with yeast stress, but if so, I think rousing would reduce stress on this powdery strain and keep it ticking over.

Notes:

At least three features of the Harvey's culture have been theorized as causing problems in the home brewery: 1) the culture comprised of two Saccharomyces cerevisiae strains plus a latent strain of Debaryomyces hansenii, each of which might behave differently across home brewing environs/worts; 2) the culture originating from the Yorkshire square family of 'Saison-like' strains, requiring regular re-circulation/rousing; and 3) it's phenolic character.

Concerning point 1, the putative 'multi-strain' composition of the Harvey's culture has been contested (Personal Comm.). After plating the Harvey's culture on malt/agar and WLN media, I detected only one colony morphology. However my dilution of yeast cultures and plating techniques are both poor.

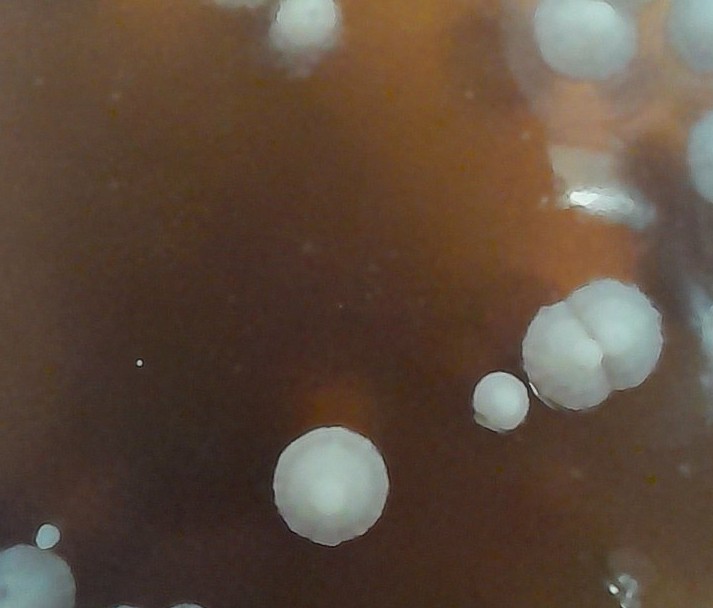

A photo of a typical colony of the Harvey's strain, grown on wort/gelatin media:

An article regarding the 'multi strain' character of Harvey's yeast described a single strain originally sourced from John Smiths, that after serial re-pitching contained two genetically identical 'strain's' plus Debaryomyces hansenii (See: https://www.beervanablog.com/beervana/2 ... 892_30493=). However the article also described the ratio of the two 'strains' changing with no or very little perceived impact on the fermentation or flavour profile of the resulting beer. I interpreted this as possibly indicative of the type of mutation found in single strain cultures when serially re-pitched, as described by McMullan (Personal Comm.). In contrast I was able to identify two strains of yeast in a sample from another regional UK brewery, each of which exhibited different morphology, brewing behaviour and flavour. In essence, the Harvey's yeast for most practical purposes could be treated as single-strain.

Regarding points 2 (Yorkshire yeast), and 3 (phenolic character), Northern Brewer has commented that:

Inspired by McMullan's Yorkshire Square setup I prepared two fermenters: one with a re-circulation loop including spreader plate/makeshift 'fish tail' and timed pump, and the 2nd a standard s/s bucket in a temperature controlled fridge. The former fermenter included a s/s coil plumbed into a circuit with a pump, under-bar chiller and STC1000 controller. A heat pad was also attached to the STC1000 unit.

A single gyle of 'Harvey's-esque' bitter was brewed using a recipe adapted from a photograph of Harvey's Log book for their Best Bitter, brewed on the 4th November 2004.

GW's 'bitter' liquor profile was used alongside Gladfield malts and home made invert sugar. On propagating the yeast from a slant, I observed it was flocculant but produced a very powdery sediment. The powdery sediment combined with good flocculation resulted in a film of yeast settling on any surface immersed in the wort, if the sediment/wort was agitated then given a few minutes to settle. This behaviour would possibly suit a Yorkshire square or Burton union type arrangement where the wort was pumped or encouraged up onto a flat, draining surface such as an upper deck/trough. In this comparison I did not attempt to separate the yeast from the wort in this manner, and simply top cropped using my usual regime (after approx 48 hours, once every 24 hours for 3 total top crops). Under the microscope the cells were even and circular, but appeared to be smaller than I am used to seeing. I don't have a means of measuring the size of cells under the microscope, so my visual assessment is subjective. Abbreviated brew notes are below:

A small amount of Gladfield Dark Chocolate malt was added to tweak the colour in place of the coloured priming sugar or caramel possibly used at the brewery (Personal Communication, b).

Liqour: aiming for a variation on Graham Wheeler's Bitter profile

Ca: 170

S04 273

Cl 137.9

Predicted pH (Brew N Water): 5.1

Total Liqour: 77L

Mash: 16L:

CaSo4: 7.8g

CaCl2: 4.2g

Sparge: 0.7ml lactic acid

Boil:

CaSo4: 29.9g

CaCl2: 15.9g

Didn't quite have enough invert No.3 so made up the difference with No.1 (approx. 1/3rd invert No.1 or 200g).

Fermentation regime: Set up a remote timer to start re-circulation after 24 hours post pitch. Unfortunately the timer only works in 15min intervals, so the re-circulation continued for longer than reported on the net for commercial breweries (between 5 and 10 minutes). When lifting the lid during re-circulation there was a lot of perceived CO2 above the beer being released. Not sure how/if the presence of the lid will have affected the results of re-circulation (i.e. possibly trapping more co2 above the beer than if the fermenter was truly 'open'. Initially I thought the regime should run from 24 hours post pitch to 36 hours post pitch, so I stopped re-circulation over night (e.g. after 12 hours of the cycle). However, later I read that re-circulation continues over a period of 36 hours (rather than from the point of pitching the yeast), so I restarted the program for an additional 12 hours (total period of re-circulation = 36 hours ignoring the 8-9 hours 'interruption' when I turned off the timer/pump). FV#2 was left undisturbed.

Sunday 19th: Took a gravity reading and small taste sample from both FV. FV#1 - light esters, very faint, almost imperceptible phenols, quite 'light' and almost clean but with a yeasty bite/aftertaste. Gravity at 1.010. FV#2 is much sweeter, pleasant, no yeast taint but phenols are more pronounced (but actually pleasant). Gravity 1.020. Started dropping temp in FV#1 to 19.5c, then 18c, then straight to 10c over 24 hours.

23/09/2021: Casked FV#1 beer with 15g fuggle dry hop, 23g table sugar and 24ml of Super S. Beer quite cloudy with yeast going into the pin. Much cloudier than I would like but no yeast bite as before. Quite a sweet flavour with some light esters, very light phenols, but generally quite 'clean' tasting. FV#2 fermenter at 19c so crashed it to 10. A taste comparison of beer from FV#2 showed increased phenols compared to FV#1 to the point that FV#2 beer could pass as 'Belgian'. Not unpleasant though, just not what you might expect for a bitter. The rousing does indeed seem to reduce the perception of phenols in the beer and also increase fermentation speed.

30/09/21: Tapped the roused version. Good clarity although not 'polished'. Reasonable head that fades leaving some lacing down the glass. Light hoppy aroma, some ripe fruit esters, very subtle phenols. Flavour is ripe fruit, light malt and hops, very subtle phenolic (more of a background subtle spice note). Very easy drinking. Light bodied but not watery. Reminds me of Harvey's best bitter but could do with an additional week conditioning to 'round out' the flavours. Drinks as a bit thin/green at the moment and could do with a little bit more sweet/mouth feel which I think will come in a week. Pleased with the phenol expression though - seems appropriate given my memory of Harvey's. Certainly quite subtle but present. Tastes like British beer (not Belgian).

06/10/2021: Pulled a pint. Lovely, subtle orangy, marmelaide hoppy notes on the nose (probably from the Pacifica hops used in place of Golding). Good frothy white head that laces the glass. Good clarity and colour, if a little pale for Harveys (lack of invert No.3, caramel). Mouthfeel is light with gentle carbonation, Notes of pear, and melon, some bitter citrus peel, perhaps some phenolic spice, but the latter is a very subtle background note that blends with the ester profile to create a superior flavour rather than being perceived as a flaw. Dry finish that leaves a pleasing malt and hops aftertaste that encourages another sip. Very nice beer. The finish is perhaps a little dry and I would like to brew it again perhaps with a less vigorous rousing regime, but altogether very nice indeed.

14/10/2021: Currently drinking pin#2 after tapping it last week. Very pleasant bitter beer. Nice loose head with good retention and light lacing down the glass. Flavour is more full bodied than the roused version, good malt and hops profile, some light fruity esters and a balanced, light, phenolic note that isn't intrusive. To be honest the phenolic note doesn't seem any more present than the roused version. Of the two beers, this is definitely the better. However I think a 'light, rouse' of perhaps 5 mins max duration at 48 hours would be beneficial to make sure the yeast does it's job (given it is so powdery). Subsequent 5 minute rousing may also be beneficial, but I can't draw conclusions about the appropriateness of that regime based on current observations. So far, from the one brewing attempt with this strain, it seems a really nice yeast and not problematic at all. I wonder if this is down to the microbiological skills of McMullan who supplied a very healthy, robust yeast than propagates well. Another explanation might be cask conditioning: this beer tastes like a traditional cask conditioned ale. Perhaps in bottle or keg form the very light phenolic nature seems more intrusive?

19/10/2021: Excellent beer. Medium bodied which seems perfectly balanced - not too heavy but also with a pleasing quality. The esters and (very light) background phenolic note are in perfect balance with the malt and hop profile which shine through cleanly. A very pleasant and easy drinking pint.

The results of this comparison may have been shaped by my use of pure O2 at a rate of 1 L/P/M for 90 seconds. This may have reduced the perceived impact of rousing compared to wort simply aerated via transfer from a height into the FV. During the first rouse I perceived a high concentration of CO2 (nasal/aroma assessment) above the beer, but this had dropped off quite noticeably during the 2nd rouse. The results obtained here may also have been shaped by the skill of McMullan in propagating a very healthy culture.

In summary, my impressions of this culture after using it ONCE, are that it produces a very pleasant UK style bitter beer with good hops and malt profile, subtle esters and a very light, almost imperceptible phenolic character that blends well with the ester character. Just like the commercial Harvey's bitter I suspect the phenolic character varies with the age, handling, and other factors affecting the condition of the beer. Nevertheless neither beer (whether roused or left to ferment undisturbed) was overly phenolic in this single comparison. I would like to brew more with this yeast and get to know it better.

Cire recently invited me to the forum and pointed me in the direction of this thread. I'm the bloke in NZ that McMullan (very kindly) sent Harvey's yeast to. I'm very happy to send some on to you DuncB if you'd like to try it too. Is there a way to send a PM on this forum? If so drop me a line and we can work something out (I'm based in Northland).

I recently did a comparison of wort fermented with the Harvey's strain roused vs. 'un-roused'. The results of this simple comparison were far from definitive but may still be of interest (see abridged notes below). My impression currently (based on little experience with the strain), is that rousing is important in encouraging a timely, healthy fermentation and reducing/limiting phenolic character. I don't know if phenols increase with yeast stress, but if so, I think rousing would reduce stress on this powdery strain and keep it ticking over.

Notes:

At least three features of the Harvey's culture have been theorized as causing problems in the home brewery: 1) the culture comprised of two Saccharomyces cerevisiae strains plus a latent strain of Debaryomyces hansenii, each of which might behave differently across home brewing environs/worts; 2) the culture originating from the Yorkshire square family of 'Saison-like' strains, requiring regular re-circulation/rousing; and 3) it's phenolic character.

Concerning point 1, the putative 'multi-strain' composition of the Harvey's culture has been contested (Personal Comm.). After plating the Harvey's culture on malt/agar and WLN media, I detected only one colony morphology. However my dilution of yeast cultures and plating techniques are both poor.

A photo of a typical colony of the Harvey's strain, grown on wort/gelatin media:

An article regarding the 'multi strain' character of Harvey's yeast described a single strain originally sourced from John Smiths, that after serial re-pitching contained two genetically identical 'strain's' plus Debaryomyces hansenii (See: https://www.beervanablog.com/beervana/2 ... 892_30493=). However the article also described the ratio of the two 'strains' changing with no or very little perceived impact on the fermentation or flavour profile of the resulting beer. I interpreted this as possibly indicative of the type of mutation found in single strain cultures when serially re-pitched, as described by McMullan (Personal Comm.). In contrast I was able to identify two strains of yeast in a sample from another regional UK brewery, each of which exhibited different morphology, brewing behaviour and flavour. In essence, the Harvey's yeast for most practical purposes could be treated as single-strain.

Regarding points 2 (Yorkshire yeast), and 3 (phenolic character), Northern Brewer has commented that:

"It's a proper Yorkshire yeast (from John Smiths) so won't reward you if you leave it undisturbed at the bottom of a fermenter like it's Whitbread B or something, it needs to be splashed about.

Also, with the usual caveats about sequencing, an old isolate was sequenced and like many of the Yorkshire yeasts was found to be a POF+ member of the saison family, as are WLP037 and WLP038. So if you think back to how people have had problems with the phenolics in WLP037, except for [McMullan] who put it through his mini-square system, it's perhaps not surprising that Harvey's hasn't worked brilliantly at homebrew level, it just needs more oxygen". (See: viewtopic.php?f=13&t=7436&p=112946&hili ... 7s#p112946)

Inspired by McMullan's Yorkshire Square setup I prepared two fermenters: one with a re-circulation loop including spreader plate/makeshift 'fish tail' and timed pump, and the 2nd a standard s/s bucket in a temperature controlled fridge. The former fermenter included a s/s coil plumbed into a circuit with a pump, under-bar chiller and STC1000 controller. A heat pad was also attached to the STC1000 unit.

A single gyle of 'Harvey's-esque' bitter was brewed using a recipe adapted from a photograph of Harvey's Log book for their Best Bitter, brewed on the 4th November 2004.

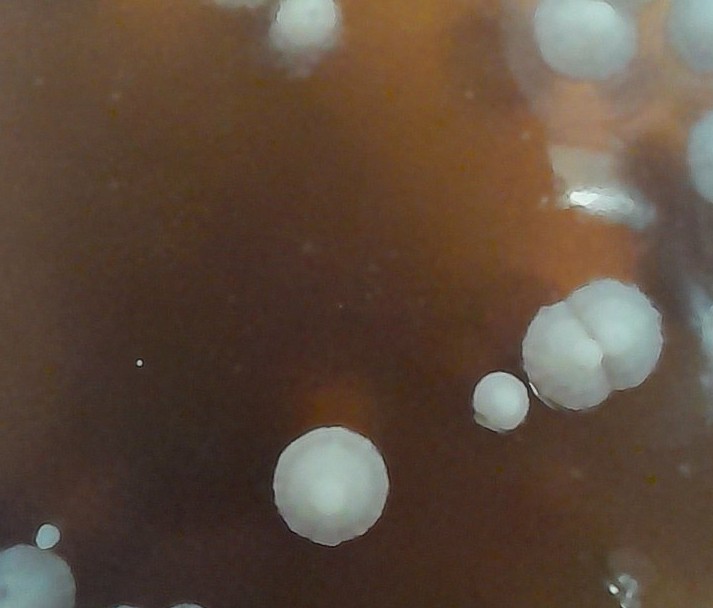

GW's 'bitter' liquor profile was used alongside Gladfield malts and home made invert sugar. On propagating the yeast from a slant, I observed it was flocculant but produced a very powdery sediment. The powdery sediment combined with good flocculation resulted in a film of yeast settling on any surface immersed in the wort, if the sediment/wort was agitated then given a few minutes to settle. This behaviour would possibly suit a Yorkshire square or Burton union type arrangement where the wort was pumped or encouraged up onto a flat, draining surface such as an upper deck/trough. In this comparison I did not attempt to separate the yeast from the wort in this manner, and simply top cropped using my usual regime (after approx 48 hours, once every 24 hours for 3 total top crops). Under the microscope the cells were even and circular, but appeared to be smaller than I am used to seeing. I don't have a means of measuring the size of cells under the microscope, so my visual assessment is subjective. Abbreviated brew notes are below:

A small amount of Gladfield Dark Chocolate malt was added to tweak the colour in place of the coloured priming sugar or caramel possibly used at the brewery (Personal Communication, b).

Liqour: aiming for a variation on Graham Wheeler's Bitter profile

Ca: 170

S04 273

Cl 137.9

Predicted pH (Brew N Water): 5.1

Total Liqour: 77L

Mash: 16L:

CaSo4: 7.8g

CaCl2: 4.2g

Sparge: 0.7ml lactic acid

Boil:

CaSo4: 29.9g

CaCl2: 15.9g

Didn't quite have enough invert No.3 so made up the difference with No.1 (approx. 1/3rd invert No.1 or 200g).

Fermentation regime: Set up a remote timer to start re-circulation after 24 hours post pitch. Unfortunately the timer only works in 15min intervals, so the re-circulation continued for longer than reported on the net for commercial breweries (between 5 and 10 minutes). When lifting the lid during re-circulation there was a lot of perceived CO2 above the beer being released. Not sure how/if the presence of the lid will have affected the results of re-circulation (i.e. possibly trapping more co2 above the beer than if the fermenter was truly 'open'. Initially I thought the regime should run from 24 hours post pitch to 36 hours post pitch, so I stopped re-circulation over night (e.g. after 12 hours of the cycle). However, later I read that re-circulation continues over a period of 36 hours (rather than from the point of pitching the yeast), so I restarted the program for an additional 12 hours (total period of re-circulation = 36 hours ignoring the 8-9 hours 'interruption' when I turned off the timer/pump). FV#2 was left undisturbed.

Sunday 19th: Took a gravity reading and small taste sample from both FV. FV#1 - light esters, very faint, almost imperceptible phenols, quite 'light' and almost clean but with a yeasty bite/aftertaste. Gravity at 1.010. FV#2 is much sweeter, pleasant, no yeast taint but phenols are more pronounced (but actually pleasant). Gravity 1.020. Started dropping temp in FV#1 to 19.5c, then 18c, then straight to 10c over 24 hours.

23/09/2021: Casked FV#1 beer with 15g fuggle dry hop, 23g table sugar and 24ml of Super S. Beer quite cloudy with yeast going into the pin. Much cloudier than I would like but no yeast bite as before. Quite a sweet flavour with some light esters, very light phenols, but generally quite 'clean' tasting. FV#2 fermenter at 19c so crashed it to 10. A taste comparison of beer from FV#2 showed increased phenols compared to FV#1 to the point that FV#2 beer could pass as 'Belgian'. Not unpleasant though, just not what you might expect for a bitter. The rousing does indeed seem to reduce the perception of phenols in the beer and also increase fermentation speed.

30/09/21: Tapped the roused version. Good clarity although not 'polished'. Reasonable head that fades leaving some lacing down the glass. Light hoppy aroma, some ripe fruit esters, very subtle phenols. Flavour is ripe fruit, light malt and hops, very subtle phenolic (more of a background subtle spice note). Very easy drinking. Light bodied but not watery. Reminds me of Harvey's best bitter but could do with an additional week conditioning to 'round out' the flavours. Drinks as a bit thin/green at the moment and could do with a little bit more sweet/mouth feel which I think will come in a week. Pleased with the phenol expression though - seems appropriate given my memory of Harvey's. Certainly quite subtle but present. Tastes like British beer (not Belgian).

06/10/2021: Pulled a pint. Lovely, subtle orangy, marmelaide hoppy notes on the nose (probably from the Pacifica hops used in place of Golding). Good frothy white head that laces the glass. Good clarity and colour, if a little pale for Harveys (lack of invert No.3, caramel). Mouthfeel is light with gentle carbonation, Notes of pear, and melon, some bitter citrus peel, perhaps some phenolic spice, but the latter is a very subtle background note that blends with the ester profile to create a superior flavour rather than being perceived as a flaw. Dry finish that leaves a pleasing malt and hops aftertaste that encourages another sip. Very nice beer. The finish is perhaps a little dry and I would like to brew it again perhaps with a less vigorous rousing regime, but altogether very nice indeed.

14/10/2021: Currently drinking pin#2 after tapping it last week. Very pleasant bitter beer. Nice loose head with good retention and light lacing down the glass. Flavour is more full bodied than the roused version, good malt and hops profile, some light fruity esters and a balanced, light, phenolic note that isn't intrusive. To be honest the phenolic note doesn't seem any more present than the roused version. Of the two beers, this is definitely the better. However I think a 'light, rouse' of perhaps 5 mins max duration at 48 hours would be beneficial to make sure the yeast does it's job (given it is so powdery). Subsequent 5 minute rousing may also be beneficial, but I can't draw conclusions about the appropriateness of that regime based on current observations. So far, from the one brewing attempt with this strain, it seems a really nice yeast and not problematic at all. I wonder if this is down to the microbiological skills of McMullan who supplied a very healthy, robust yeast than propagates well. Another explanation might be cask conditioning: this beer tastes like a traditional cask conditioned ale. Perhaps in bottle or keg form the very light phenolic nature seems more intrusive?

19/10/2021: Excellent beer. Medium bodied which seems perfectly balanced - not too heavy but also with a pleasing quality. The esters and (very light) background phenolic note are in perfect balance with the malt and hop profile which shine through cleanly. A very pleasant and easy drinking pint.

The results of this comparison may have been shaped by my use of pure O2 at a rate of 1 L/P/M for 90 seconds. This may have reduced the perceived impact of rousing compared to wort simply aerated via transfer from a height into the FV. During the first rouse I perceived a high concentration of CO2 (nasal/aroma assessment) above the beer, but this had dropped off quite noticeably during the 2nd rouse. The results obtained here may also have been shaped by the skill of McMullan in propagating a very healthy culture.

In summary, my impressions of this culture after using it ONCE, are that it produces a very pleasant UK style bitter beer with good hops and malt profile, subtle esters and a very light, almost imperceptible phenolic character that blends well with the ester character. Just like the commercial Harvey's bitter I suspect the phenolic character varies with the age, handling, and other factors affecting the condition of the beer. Nevertheless neither beer (whether roused or left to ferment undisturbed) was overly phenolic in this single comparison. I would like to brew more with this yeast and get to know it better.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)