Sam listed 1 pack. I can tell you from experience you need two. I don't remember the pricing.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Weldless brew stand.

- Thread starter Bender

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Question for you guys on the hardware packs. It says I must buy packs of 50 at $6.45 per pack. Does that mean there are 50 bolts in a pack for $6.45 or does that mean I have to buy 50 packs at $6.45. I am thinking it means the former since I can just put a pack in my cart at $6.45. However, I just wanted clarification since the current price seems cheaper than the $12.89 shown on the Wallace inventory sheet and that doesn't seem right to me.

Also, Would you recommend buying 2 packs of this hardware?

Thanks for the help!

That's about what I paid a few months ago... each pk of 50 comes with 50 bolts, nuts, and washers. I bought 2 packages... and actually had to go to Menards and get some additional because of a few extra things I added to my frame. 2 packages MINIMUM.

Ciliorozo

Well-Known Member

Excellent. Thanks guys! I can't brew right now because we are in the process of moving and the house must stay in show condition, so I am putting a RIMS rig together so that I can jump right into brewing in our next residence. SWMBO is giving me a dedicated brewing space and has approved this project! And since I do not have the skill or tools needed to weld a stand, I am using this erector set type idea!

Thanks again!

Thanks again!

Yeah I bought 2 packs initially and ended up ordering a 3rd. I put in a few extra braces and such and needed that 3rd pack.

Ciliorozo

Well-Known Member

Ok I am sold! A third pack will be mine!

BrewerRick

Active Member

Question for you guys on the hardware packs. It says I must buy packs of 50 at $6.45 per pack. Does that mean there are 50 bolts in a pack for $6.45 or does that mean I have to buy 50 packs at $6.45. I am thinking it means the former since I can just put a pack in my cart at $6.45. However, I just wanted clarification since the current price seems cheaper than the $12.89 shown on the Wallace inventory sheet and that doesn't seem right to me.

Also, Would you recommend buying 2 packs of this hardware?

Thanks for the help!

Yes buy at least two packs...There are 50 bolts, 50 washers, and 50 nuts. I would almost recommending buy a third for any extra brasing, mounts, etc. I ran out of washers, because I was doubling up on them (one on each side).

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

J-Malone

Well-Known Member

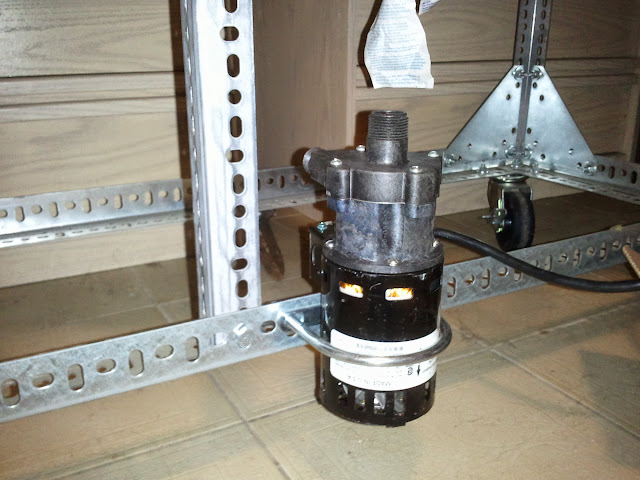

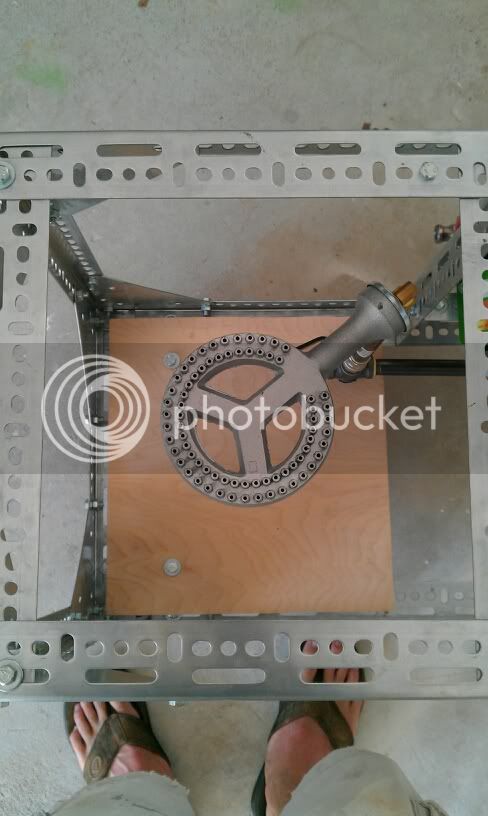

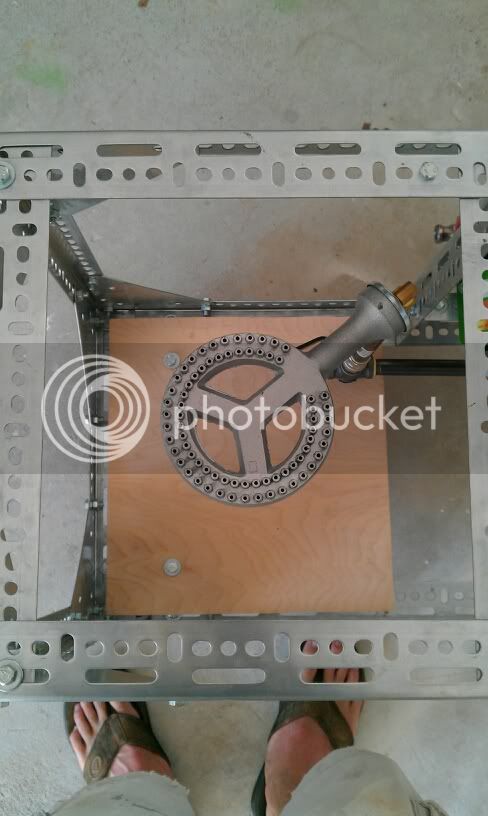

Just to prove I am not making it up that I am building one of these:

Just based on the research I have done, you are going to want to reposition that pump. I am fairly certain you will have priming issues if you orient it that way. Standard orientation is inlet down or straight out...if you leave it like that I am certain that you will get air in the line and lose prime. Just a tip

Supposedly the beauty of the top inlet pump is ease of priming. The liquid will flow straight down into the pump head, and any air bubbles should be fairly unrestricted in flowing upwards and out of the way. I have since repositioned the head on the pump so that the outlet is pointing to the left instead of back into the stand.

Supposedly the beauty of the top inlet pump is ease of priming. The liquid will flow straight down into the pump head, and any air bubbles should be fairly unrestricted in flowing upwards and out of the way. I have since repositioned the head on the pump so that the outlet is pointing to the left instead of back into the stand.

I think it will work just fine the way you have it now. IMO, it doesn't make any difference how you position the pump so long as you have a way to purge the pump head such as with a bleeder valve or simply detaching a hose on the outlet side. I think Walter of March Pumps said that the pump head should not be positioned at the bottom when mounting the pumps vertically. IIRC, the reason for this was the potential for air to become trapped in the impeller magnet pocket and this would deprive the impeller shaft of lubrication. I think there was something about excessive wear on the thrust bearings too, but I'm not sure about that. I have my Little Giant mounted vertically with the pump head down and have had no problems at all. I think there is a difference in the thrust bearings though which might have something to do with that. LG told me that the pump could be mounted in any position so I went with that. This position puts the pump head at the lowest level possible and both ports are nearly in the same horizontal plane. Plumbed properly, a pump should be very easy to prime. Mine is.

I put the fittings on my pump tonight. I'm a little concerned about the proximity of the inlet tube to the burner and the chance of melting the tubing, but I can probably bolt on a metal plate as a heat shield.

Decided to make a thread for my build as a whole rather than flood this post with pics:

https://www.homebrewtalk.com/f51/my-brew-stand-fermentation-chamber-build-234387/

https://www.homebrewtalk.com/f51/my-brew-stand-fermentation-chamber-build-234387/

sam

Well-Known Member

Sam listed 1 pack. I can tell you from experience you need two. I don't remember the pricing.

Whoops, yes... sorry. The quantity I listed was wrong. The price I listed was for 2 packs. It cost me $12.90 for 2 packs and I think I used just about every single bolt so buying a third pack is probably a good idea.

-Sam

Mike_A

Well-Known Member

Figured I'd post this up here as a "thanks" to Sam for being the inspiration for my brew stand as well! I scaled Wallace up a little bit to accommodate my 25gal kettles, hope you don't mind.

For reference, I used a ton of bolts, nuts, washers and lock washers since I noticed the bolt heads are barely wider than the holes/slots on the steel. I probably went through the equivalent of 4 or 5 packs.

For reference, I used a ton of bolts, nuts, washers and lock washers since I noticed the bolt heads are barely wider than the holes/slots on the steel. I probably went through the equivalent of 4 or 5 packs.

Thought I''d post a shot of my rig I just completed (still waiting for a few more quick disconnects and silicon tubing). Basically, a "Brutus 10" leveraging Sam's "Wallace" idea of using slotted angle. I was going to build a welded square tube design but liked the flexibility that the slotted angle offered (wanted the option to adjust things if needed).

Strongbad52

Well-Known Member

While not as blingy as all the diamond plate, i finally got the propane hard plumbed

sam

Well-Known Member

Wow! I'm loving all the pictures. Anyone have some pictures of their stand in action?

Here's one from last August... A true "no-pants" brewer (OSHA would not approve), my 4-year-old helping me dough-in.

Here's one from last August... A true "no-pants" brewer (OSHA would not approve), my 4-year-old helping me dough-in.

Biscostew

Well-Known Member

Lots of nice rigs in this thread. I have a question in regards to direct fire mashing and temperature control. I have been looking into threads on thermocouplers, would this be the approach to monitor the temp leaving the ball valve at the bottom and returning throught the top of the mash tun? Two different thermomcouplers hooked up to a digital thermometer of some sort? I can't tell if these are used for non automated systems like mine or the more traditional Brutus 10 automated type stand. Any info would be greatly appreciated on how you regulate mash temps with this set up.

Strongbad52

Well-Known Member

1 new gasline and 2 homedepot trips later finally got a leak free propane test. Going to do the zinc coating burn off later today and then do a 10 gallon break-in batch of Hopsecutioner.

Thought I''d post a shot of my rig I just completed (still waiting for a few more quick disconnects and silicon tubing). Basically, a "Brutus 10" leveraging Sam's "Wallace" idea of using slotted angle. I was going to build a welded square tube design but liked the flexibility that the slotted angle offered (wanted the option to adjust things if needed).

love the set up. I decieded to do a brutus 10 welded rig but still looking over this thread and might change my mind again.

Can you give some detail on your temp control? I don't see the gas line control, are you turning on and off the burners?

I pretty much have duplicated the typical Brutus 10 (outside of slotted angle iron). I have two Asco valves that are controlled via thermal probes from each of my Runco controllers.

Nice. What's the regulator looking device you are using for the pilots?

agezzi

Well-Known Member

V-Twin said:I use standing pilots and my burners are connected to Asco valves for the HLT and Mash tun.

Did you use compression fittings or flared fittings for the pilots. I'm about to this point in my build.

I used brass compression fittings and aluminum tubing (vs. copper). I just drilled small holes on each side of a brass plug for each pilot. I have needle valves for each pilot so I can adjust the flame. Initially I was worried about how I was going to build the pilots as I couldn't find much info in the forums. Turned out to be pretty easy.

Found my next project, subscribed.

Strongbad52

Well-Known Member

Excellent build!

That's pretty similar to mine (in construction materials, anyway):

http://www.lancedrolet.com/?p=7

But I didn't want to shell out for the pumps, so mine is a 3 tier...

Thanks man, I especially appreciate the detailed measurements.

BeerGuy1000

Well-Known Member

How did you guys build the switch box for your pumps, did you just plug your pumps into the box so you can turn them off/on or did you wire them into the box, I would love to do that any info would help.

Yeah don't need the expensive heavy duty casters. As I understand it anyhow you divide up the weight. So if you have four of them you multiply their weight level by four. So 100 pound wheels on each corner will support a total of 400.

I just picked up the steel from the Aurora, OH McMaster-Carr to start my build (hopefully done by the start of the school year).

I'll probably make all of the cuts this weekend, but for now I'm trying to gather a list of exactly what I need to order for the propane plumbing.

I only want 2 burners as I have an igloo MLT and don't really want to use a keg in the future. I am thinking that I will use 2 of these burners, 1 for the HLT and 1 for the BK. http://www.agrisupply.com/bg-high-pressure-cast-iron-burner-/p/64494/cn/5400001/

Other than that I'm not sure exactly what else must be ordered. I saw some people say they don't come with a jet, etc.

Also which regulator and hoses are required with those burners?

Obviously I am brand new to plumbing and the like and I apologize if this has been beaten to death.

Thanks for ANY help!

I'll probably make all of the cuts this weekend, but for now I'm trying to gather a list of exactly what I need to order for the propane plumbing.

I only want 2 burners as I have an igloo MLT and don't really want to use a keg in the future. I am thinking that I will use 2 of these burners, 1 for the HLT and 1 for the BK. http://www.agrisupply.com/bg-high-pressure-cast-iron-burner-/p/64494/cn/5400001/

Other than that I'm not sure exactly what else must be ordered. I saw some people say they don't come with a jet, etc.

Also which regulator and hoses are required with those burners?

Obviously I am brand new to plumbing and the like and I apologize if this has been beaten to death.

Thanks for ANY help!

Definitely strong... the most expensive part of my build were the casters because I got ones that were rated at 400lbs each. One keg filled to the top with water weighs in at about 150 or so lbs. I filled all 3 kegs to the top with cold water and stood on the frame while kind of bouncing up and down all while a friend rolled me around a little just to see if the casters seized under the weight. Casters worked fine and nothing budged, bent, or squeaked. I've been using mine for over 2 years (25 batches or so) and it seems as strong as ever.

I absolutely love the "Hold my beer, watch this" method of testing...

rtp-brew

Active Member

I am thinking that I will use 2 of these burners, 1 for the HLT and 1 for the BK. http://www.agrisupply.com/bg-high-pressure-cast-iron-burner-/p/64494/cn/5400001/

Other than that I'm not sure exactly what else must be ordered. I saw some people say they don't come with a jet, etc.

I just started the same build. Those burners arrived yesterday with jets, which I too was not expecting.

The jet isn't stamped anywhere. No idea of the orifice size. I'm converting to low pressure propane, so I figure I'm going to have to drill them out anyway. Waiting on my regulator to arrive, so not that far in the plan yet.

I just started the same build. Those burners arrived yesterday with jets, which I too was not expecting.

The jet isn't stamped anywhere. No idea of the orifice size. I'm converting to low pressure propane, so I figure I'm going to have to drill them out anyway. Waiting on my regulator to arrive, so not that far in the plan yet.

Why did you decide to convert them to low pressure, what's the benefit?

Thanks and good luck on your build

BrewerRick

Active Member

How did you guys build the switch box for your pumps, did you just plug your pumps into the box so you can turn them off/on or did you wire them into the box, I would love to do that any info would help.

I wired mine into a box with two separate switches (one for each pump) in them, then I also wired in a cord that I cut on one end and left the plug on the other end so I could power both switches with one power feed. Just make sure your cord is correctly sized to handle the current that your total load will draw.

rtp-brew

Active Member

Why did you decide to convert them to low pressure, what's the benefit?

Thanks and good luck on your build

I was planning on direct firing the MT, so some finer control there. Supposedly adding automation is a little easier/cheaper down the road. We'll see about that I guess.

Also having stood next to a KAB6 while it was heating 26 gallons, it's kind of overkill. There is a ton of wasted heat; burning leg hairs, melting nearby plastic buckets, generally not helping to heat the stuff in the pot.

Taking my weldless brew rig on her MAIDEN VOYAGE as we speak... brewing Ed Worts pale ale... already half way through my boil, and she is performing EXCELLENT!!!! Couldn't be happier with this design! Been working on this on and off since Xmas. FINALLY brewing on it. First All Grain batch too!

Taking my weldless brew rig on her MAIDEN VOYAGE as we speak... brewing Ed Worts pale ale... already half way through my boil, and she is performing EXCELLENT!!!! Couldn't be happier with this design! Been working on this on and off since Xmas. FINALLY brewing on it. First All Grain batch too!

SUCCESS! I hit and maintained all of my temps, fly sparged successfully, and hit 1.052 OG when Beersmith expected... 1.052 OG! Crazy. Also, with my IC and a whirlpool return, I cooled from boiling to 75F in 10 minutes...

Love this rig.

Similar threads

- Replies

- 1

- Views

- 1K

- Replies

- 12

- Views

- 2K

- Replies

- 73

- Views

- 7K