Miscue

Member

http://www.amazon.com/dp/B0009JXYQ4/?tag=skimlinks_replacement-20

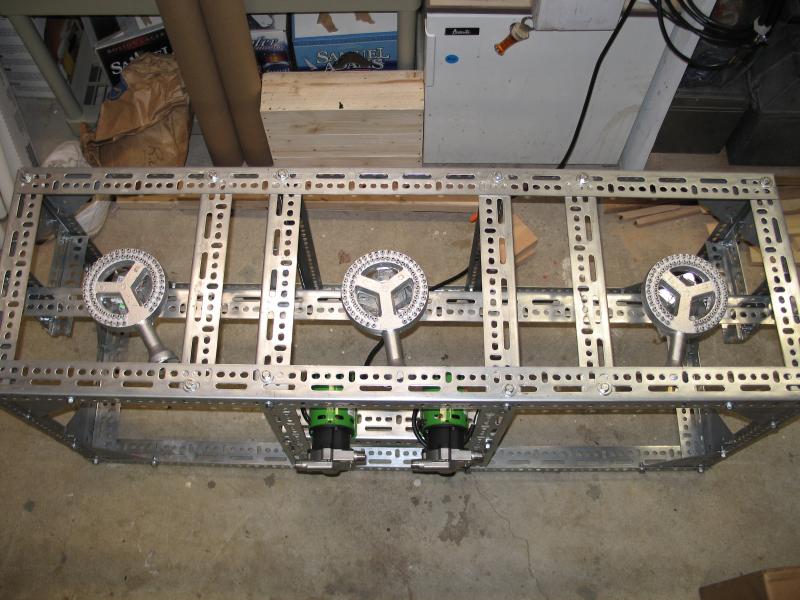

What do you think about going with two of these burners for this brewstand? Looking for something I can use without the stand while I'm putting together all the parts.

Cheers,

Brad

What do you think about going with two of these burners for this brewstand? Looking for something I can use without the stand while I'm putting together all the parts.

Cheers,

Brad

Last edited by a moderator:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)