craigsphillips - you need to read the thread title Electrical Primer. It sounds to me like you are entering an area that you have little or no knowledge of and that will get you or someone hurt really quickly. There are alot of nuances that come with electrcity. Its not just on or off like gas. I have an all electric system and spent almost a year researching and building it. Good luck!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RIMS for Dummies

- Thread starter Sawdustguy

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

craigsphillips

Well-Known Member

craigsphillips - you need to read the thread title Electrical Primer. It sounds to me like you are entering an area that you have little or no knowledge of and that will get you or someone hurt really quickly. There are alot of nuances that come with electrcity. Its not just on or off like gas. I have an all electric system and spent almost a year researching and building it. Good luck!

Pickles - I will look up the thread and read it. Your concerns are appreciated. I've been researching this set up for months, but I'm just about ready to buy my components and wanted to be sure the pieces I already have are compatible with ones that I'm looking to buy. I've got the ability and experience necessary to build and assemble the system, just needed a little help making sure I have compatible components. Thanks for your concerns and I'll read the post you've recommended.

While the controller is rated at 10 Amps it would be better in the long run to spend a bit more and go with a SSR to carry the heavy loads of the element. This will make it much less likely to have problems when you try to tun the relay and the controller connectors at rated amperage and have a not quite tight enough connection heat up and and burn up the controller. If it were my choice I would look at the SSR output controller models and a SSR with a heat sink, this will give you more control method choices now rather than finding out later that the relay output is not what you need. As to the water heater elements, when the voltage is reduced 50% the wattage is reduced to 25% of original rating, 4500 watts @240 volts = 1125 Watts @120 volts. When looking for the heating elements look for the most element length you can find as surface temperature on the element is a function of surface area to dissipate heat, longer element equals lower surface temperature.

newrbrewer

Active Member

- Joined

- May 28, 2008

- Messages

- 30

- Reaction score

- 0

Moved to new post

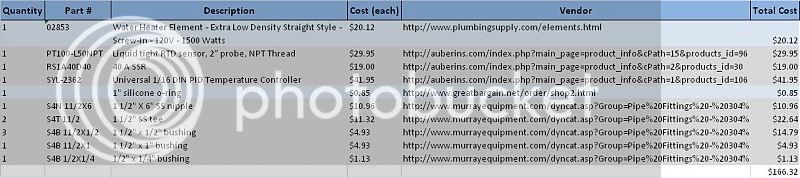

I purchased all of the parts listed in the original post except I went with the 1.5" SS tubing. I'm getting ready to wire everything together and am wondering if the power cord can be 14 gauge or if it need to be heavier. Also wondering about the internal wiring size.

Thanks!

Thanks!

I purchased all of the parts listed in the original post except I went with the 1.5" SS tubing. I'm getting ready to wire everything together and am wondering if the power cord can be 14 gauge or if it need to be heavier. Also wondering about the internal wiring size.

Sorry, I found exactly what I was looking for in the Electric Primer

I found this extension cord on Harbor Freight's website. It's a 12 gauge cord but it says it's only rated for 15 amps. Could this be because of the plugs? Perhaps I can cut off the plugs and solder 20 amp plugs to the ends?

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$1.91

$29.95

Mastering Homebrew: The Complete Guide to Brewing Delicious Beer (Beer Brewing Bible, Homebrewing Book)

Goodwill Retail Services, Inc.

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

paledragon

Well-Known Member

for short runs of wire, 12 gauge can carry 20 amps. when you get into longer runs (e.g. an extension cord), you need to start derating the current carrying capacity of the wire. that's why there are 15 amp plugs on it.

when i had a herms system, i bought a 12 gauge extension cord and chopped it into smaller chunks (<10 feet) to run the heating elements. also, you don't have to solder plugs on. if you take a trip to lowes or home depot, check out the replacement plugs. you can just screw the wires in place.

p.d.

when i had a herms system, i bought a 12 gauge extension cord and chopped it into smaller chunks (<10 feet) to run the heating elements. also, you don't have to solder plugs on. if you take a trip to lowes or home depot, check out the replacement plugs. you can just screw the wires in place.

p.d.

for short runs of wire, 12 gauge can carry 20 amps. when you get into longer runs (e.g. an extension cord), you need to start derating the current carrying capacity of the wire. that's why there are 15 amp plugs on it.

Thanks paledragon. Looking at the HB site I see that even their 10 foot cord is rated for 15 amps. I need to measure the distance from my kitchen 20 amp outlet to the brewing area in my garage but I'm going to need at least 25 feet for sure. Should I be looking for 10 gauge instead for that distance?

Sawdustguy

Well-Known Member

Thanks paledragon. Looking at the HB site I see that even their 10 foot cord is rated for 15 amps. I need to measure the distance from my kitchen 20 amp outlet to the brewing area in my garage but I'm going to need at least 25 feet for sure. Should I be looking for 10 gauge instead for that distance?

A larger gauge certainly is not going to hurt you.

Thanks paledragon. Looking at the HB site I see that even their 10 foot cord is rated for 15 amps. I need to measure the distance from my kitchen 20 amp outlet to the brewing area in my garage but I'm going to need at least 25 feet for sure. Should I be looking for 10 gauge instead for that distance?

FWIW, I'm running a 120vac element and a march pump on a 15 amp GFCI circuit, and I have not tripped the breaker once in 4 brews. I know it's pushing the envelope for amperage, but it's working for me.

- Joined

- Nov 18, 2008

- Messages

- 2,058

- Reaction score

- 25

FWIW, I'm running a 125vac element and a march pump on a 15 amp GFCI circuit, and I have not tripped the breaker once in 4 brews. I know it's pushing the envelope for amperage, but it's working for me.

How many watts is your element?

How many watts is your element?

1500 watts.

paledragon

Well-Known Member

The interesting thing about breakers is that their rating is not absolute. You can temporarily pull more than 15 amps on a 15 amp breaker. When I was researching definite purpose (i.e. Low amp) breakers for my control panel, I was frequently looking at spec sheets that had graphs of trip time versus overage. If I remember right it can take awhile to trip if you're near its rating, like 15.1 amps on a 15 amp breaker.

- Joined

- Nov 18, 2008

- Messages

- 2,058

- Reaction score

- 25

1500 watts.

I don't think you are really pushing the envelope with a 1500 watt element and a March pump on a 15 amp breaker.

I don't think you are really pushing the envelope with a 1500 watt element and a March pump on a 15 amp breaker.

Probably not. 13.9 amps, max. Funny thing is I had a 20 amp receptacle wired with 14-3 romex to a 15-amp circuit breaker. I replaced the receptacle with a GFCI and it's working fine. Just wanted to let jerryalan know that he might be able to save some money and run a pump and 120vac element on an existing 15-amp circuit. 10-gauge power cable is not cheap.

- Joined

- Nov 18, 2008

- Messages

- 2,058

- Reaction score

- 25

Probably not. 13.9 amps, max. Funny thing is I had a 20 amp receptacle wired with 14-3 romex to a 15-amp circuit breaker. I replaced the receptacle with a GFCI and it's working fine. Just wanted to let jerryalan know that he might be able to save some money and run a pump and 120vac element on an existing 15-amp circuit. 10-gauge power cable is not cheap.

Gotcha. I built a small "portable" control box, that has a PID controlled outlet for a 1500 watt RIMs heater, and a switched outlet for a March pump. I built it so I could plug it in if I was brewing at someones house and only had a 15amp outlet available.

I tested the box with a 1680 watt heat gun running in 50% manual mode AND a March pump running continuous for 3 hours.

I used a 12 gauge cord and have not had any problems.

Probably not. 13.9 amps, max. Funny thing is I had a 20 amp receptacle wired with 14-3 romex to a 15-amp circuit breaker. I replaced the receptacle with a GFCI and it's working fine. Just wanted to let jerryalan know that he might be able to save some money and run a pump and 120vac element on an existing 15-amp circuit. 10-gauge power cable is not cheap.

I'll try to run the RIMS system on the garage outlet with a GFCI and one of my short 14 gauge cords. If I run into problems I'll plug it into the dryer outlet instead. I have the 120v 1500w element so it should be fine.

Thanks for the info!

I bought these parts and neglected to get a heat sink since it is not on the parts list.

Does anyone run a RIMS tube without the heatsink or was it just an oversight on this list? I think I thought at the time the 40 amp SSR had some sort of built in heat sink. Otherwise I don't see the point in buying the 40 amp SSR over the 25 amp one.

Thanks. I appreciated all the information and parts #'s.

Sawdustguy

Well-Known Member

You are going to need a heatsink. There is going to be no way around it. They are very inexpensive.

erikrocks

Well-Known Member

Quick electrical question:

Should I ground my RIMS to the SS tube or to a screw inside the box. Or does it matter?

Should I ground my RIMS to the SS tube or to a screw inside the box. Or does it matter?

- Joined

- Nov 18, 2008

- Messages

- 2,058

- Reaction score

- 25

Quick electrical question:

Should I ground my RIMS to the SS tube or to a screw inside the box. Or does it matter?

All the above... anything metal should be grounded. Depending on how you attach your box to the RIM's Tube, the connection may bond the two, but if not, then you need to ground both.

Ed

erikrocks

Well-Known Member

All the above... anything metal should be grounded. Depending on how you attach your box to the RIM's Tube, the connection may bond the two, but if not, then you need to ground both.

Ed

I forgot to add that my box is hard plastic (and it's connected to the tube through a heavy cord). I'll run the ground wire to my tube, but I'm not sure a screw inside the plastic box would be sufficient.

- Joined

- Nov 18, 2008

- Messages

- 2,058

- Reaction score

- 25

I forgot to add that my box is hard plastic (and it's connected to the tube through a heavy cord). I'll run the ground wire to my tube, but I'm not sure a screw inside the plastic box would be sufficient.

Unless the box is a specialized conductive box, there is no need to ground it and you can't use it as a path to ground the tube. You will need to find a way to get a good electrical connection between the tube and ground.

Ed

erikrocks

Well-Known Member

I can basically run the green ground from the male plug and fasten it to the brew stand. I'm assuming this will work?

Sawdustguy

Well-Known Member

All the above... anything metal should be grounded. Depending on how you attach your box to the RIM's Tube, the connection may bond the two, but if not, then you need to ground both.

Ed

Ed,

If you will allow me to expand on that a little. Everything should be grounded to one point. In other words, all gounds should meet at one tie point. For those of us who are automating and using instrumentation, picking up ground at many different points can lead to ground loops which can introduce noise into our measurement circuits. When measuring temperature the signal is just a few millivolts and the noise generated from ground loops can affect the signal. Care must be taken to isolate our instrumentation ground from earth ground also.

erikrocks

Well-Known Member

So here's my question:

I'm using a heavy duty extension cord and a hard plastic box from Lowes. I cut the extension cord in half and cut off the female end, so the male end goes into the wall and into the box where it connects to the electronics, then the other piece goes out the box and to the heating element/tube. Can I just re-join the green ground inside the box and then tie it to the U clamp that holds the tube to my brewstand? Or do I have to make a stop in the box itself?

I'm using a heavy duty extension cord and a hard plastic box from Lowes. I cut the extension cord in half and cut off the female end, so the male end goes into the wall and into the box where it connects to the electronics, then the other piece goes out the box and to the heating element/tube. Can I just re-join the green ground inside the box and then tie it to the U clamp that holds the tube to my brewstand? Or do I have to make a stop in the box itself?

- Joined

- Nov 18, 2008

- Messages

- 2,058

- Reaction score

- 25

Depending on the "electronics" you have in your plastic box, they will likely need to be grounded as well. So you will probably need a ground terminal inside the box.

You need a solid electrical connection for all grounds. You can use the "U Bolts" to ground the tube if connected properly.

You need a solid electrical connection for all grounds. You can use the "U Bolts" to ground the tube if connected properly.

erikrocks

Well-Known Member

I have a PID + 25amp SSR/heatsink (and a switch & fuse) in the box. Very simple. The element is 1500watt ULD.

How do I ground the SSR & PID?

How do I ground the SSR & PID?

- Joined

- Nov 18, 2008

- Messages

- 2,058

- Reaction score

- 25

No ground required for the PID, SSR, or Fuse.

What kind of switch are you using?

What kind of switch are you using?

erikrocks

Well-Known Member

Great. Thanks.

The switch is a generic on/off toggle from lowes.

The switch is a generic on/off toggle from lowes.

Emian

Well-Known Member

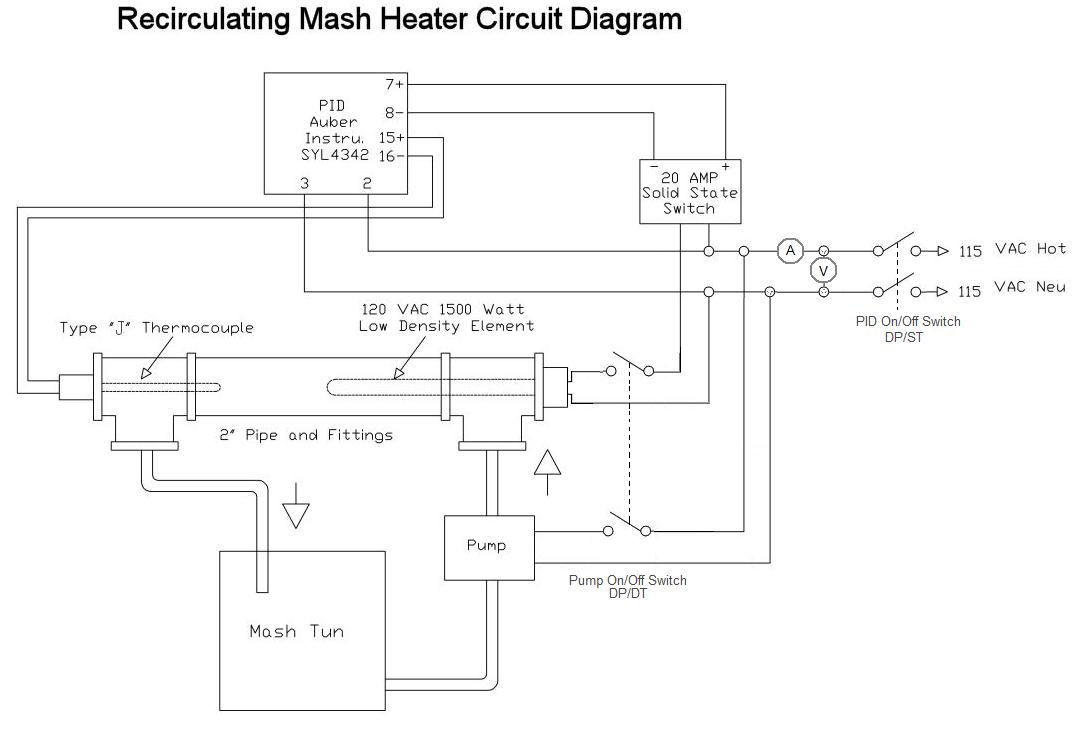

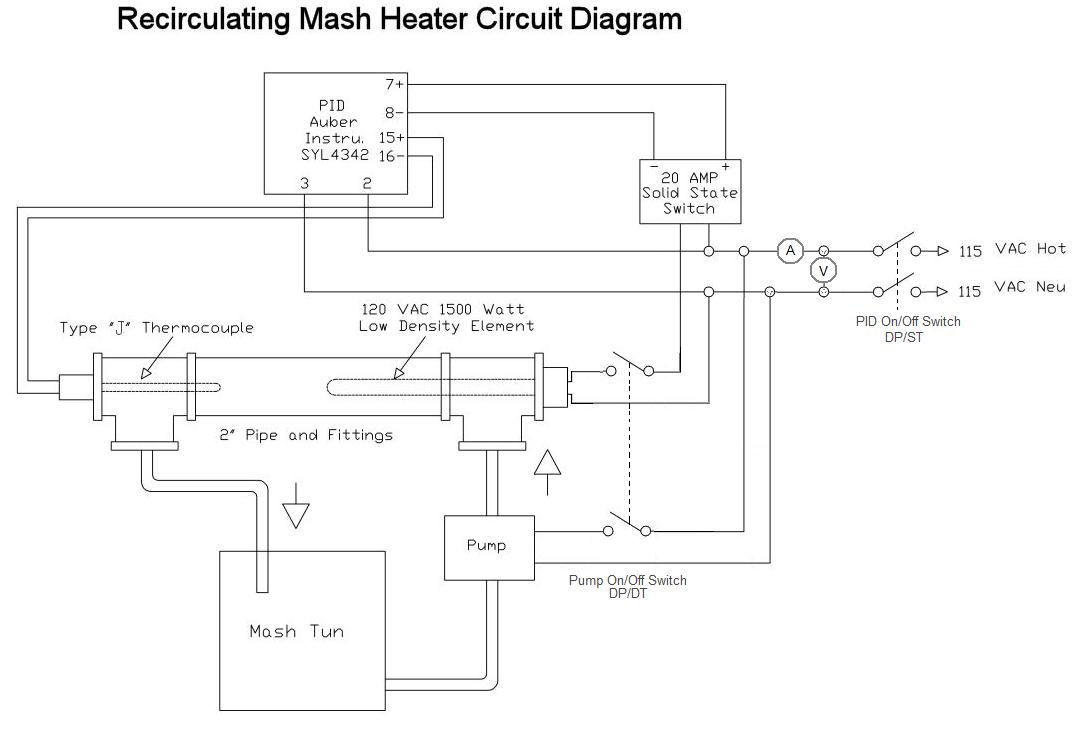

I've really enjoyed this thread. I have ordered a 20g Mash Tun with RIMS fittings from Stout Tanks and Kettles. It'll be here in Jan, so I'm going to start my wiring. This has been very helpful. In looking at your diagram, I think I would like to have it so that the heater element will not come on unless the pump is running. I would also like to put a volt meter and ammeter on the circuit. Does anyone see an issue with this slight modification?

- Joined

- Nov 18, 2008

- Messages

- 2,058

- Reaction score

- 25

I've really enjoyed this thread. I have ordered a 20g Mash Tun with RIMS fittings from Stout Tanks and Kettles. It'll be here in Jan, so I'm going to start my wiring. This has been very helpful. In looking at your diagram, I think I would like to have it so that the heater element will not come on unless the pump is running. I would also like to put a volt meter and ammeter on the circuit. Does anyone see an issue with this slight modification?

...

Looks good to me provided the DPDT switch you use will handle the RIM's element current.

Ed

ScottSA

Active Member

does anyone have problems with the element having burned wort covering it? mine will have crusty black stuff every time. brew comes out fine though.

klyph

Well-Known Member

Sounds like you aren't recirculating fast enough, or you have a really high watt density element, or both. The RIMS tube shouldn't scorch the wort.

Sawdustguy

Well-Known Member

does anyone have problems with the element having burned wort covering it? mine will have crusty black stuff every time. brew comes out fine though.

I am surprised it has not affected the taste of the beer. The RIMS should never ever scortch the wort like that. Something is very wrong.

- Joined

- Nov 18, 2008

- Messages

- 2,058

- Reaction score

- 25

does anyone have problems with the element having burned wort covering it? mine will have crusty black stuff every time. brew comes out fine though.

Where is your temp probe and what kind of controller are you using?

ScottSA

Active Member

i have it setup like this post shows. I'm using an Auber PID with SSR and 1500W element. I could probably circulate faster, but usually i'm running full bore.

- Joined

- Nov 18, 2008

- Messages

- 2,058

- Reaction score

- 25

i have it setup like this post shows. I'm using an Auber PID with SSR and 1500W element. I could probably circulate faster, but usually i'm running full bore.

The PID should prevent the wort in the tube from getting too much higher than your setpoint. I say "too much higher", because it will depend on your PID tuning. But as Guy said, if you have had constant flow it really should not be a problem. You said the element has "crusty wort" on it, but I wonder if it is really burnt?

Ed

klyph

Well-Known Member

How often and how fast does the element cycle?

Quick question. If I put together a similar unit as the RIMS system using a 4500 W 240V heating element, approximately what temp would the fluid exit at? I've seen how a RIMS system can be beneficial, but without spending a lot of money, I thought maybe this little unit could be used as an instant hot water heater for immediate fly sparge water. The water would only be used at an approximate rate of .15-.2 gpm for sparging right? Is this stupid? OK, OK... Maybe not so quick of a question.

Similar threads

- Replies

- 0

- Views

- 567

- Replies

- 5

- Views

- 3K

- Replies

- 1

- Views

- 603