CWoodard

Member

- Joined

- Aug 8, 2012

- Messages

- 9

- Reaction score

- 2

This is about stuck fermentation in a cider; yes there are other threads about dealing with preservatives like potassium sorbate (k-sorb).

Problem: Very slow / stuck fermentation

Brew: 5 gallons of Nature's Nectar Apple Cider (with potassium sorbate, but the raw cider "requires refrigeration"... so there can't be that much preservative... right?)

- Starting gravity 1.072 by hydrometer

- Oxygen aeration by stone before pitch

- 8 Cups light brown sugar, 200g blueberries, 4 sautéd jalapeños 10 cinnamon sticks (yes, it's the best cider recipe you'll ever have)

Yeast: 4x 1 liter starters of 1/2 pack of Nottingham high performance yeast, decanted, pitched slurry. Also pitch one dry pack (had previous success with this yeast)

I'm hoping someone can give me some ideas of what I haven't considered trying to ferment this cider. I've made many ciders before, however this season I didn't read my label closely enough, and see that my cider had potassium sorbate in it. Yes, I know it's bad for yeast, and that it coats yeast inhibiting their budding/reproductive cycle. But I've also heard/read a lot of "you can overcome the k-sorb with lots of yeast." I've been brewing for 15 years (this is to demonstrate I hopefully haven't made any rookie mistakes). Knowing I had the k-sorb to overcome, I made 4 one-liter yeast starters (stir plate, great bubbling, big slurry, decanted and pitched).

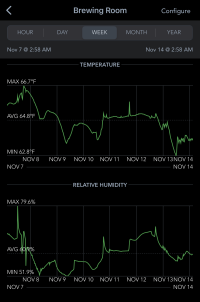

Cider is in a 6 gallon glass carboy (star-san → one-step cleaner) and is currently on day 7. Gravity has stayed at 1.072 since starting (sampled every other day). When I shake the carboy, I get violent bubbling which stops almost immediately after I quit shaking it. There has been no changes in turbidity or anything to indicate a contamination, and the cider still tastes amazing (minus the fermentation). Temperature has been relatively constant in the room (see photo) and carboy is in an insulated jacket; this is within the recommended temperature range for Nottingham Yeast.

I appreciate any thought you folks can throw my way! Thank you!

Problem: Very slow / stuck fermentation

Brew: 5 gallons of Nature's Nectar Apple Cider (with potassium sorbate, but the raw cider "requires refrigeration"... so there can't be that much preservative... right?)

- Starting gravity 1.072 by hydrometer

- Oxygen aeration by stone before pitch

- 8 Cups light brown sugar, 200g blueberries, 4 sautéd jalapeños 10 cinnamon sticks (yes, it's the best cider recipe you'll ever have)

Yeast: 4x 1 liter starters of 1/2 pack of Nottingham high performance yeast, decanted, pitched slurry. Also pitch one dry pack (had previous success with this yeast)

I'm hoping someone can give me some ideas of what I haven't considered trying to ferment this cider. I've made many ciders before, however this season I didn't read my label closely enough, and see that my cider had potassium sorbate in it. Yes, I know it's bad for yeast, and that it coats yeast inhibiting their budding/reproductive cycle. But I've also heard/read a lot of "you can overcome the k-sorb with lots of yeast." I've been brewing for 15 years (this is to demonstrate I hopefully haven't made any rookie mistakes). Knowing I had the k-sorb to overcome, I made 4 one-liter yeast starters (stir plate, great bubbling, big slurry, decanted and pitched).

Cider is in a 6 gallon glass carboy (star-san → one-step cleaner) and is currently on day 7. Gravity has stayed at 1.072 since starting (sampled every other day). When I shake the carboy, I get violent bubbling which stops almost immediately after I quit shaking it. There has been no changes in turbidity or anything to indicate a contamination, and the cider still tastes amazing (minus the fermentation). Temperature has been relatively constant in the room (see photo) and carboy is in an insulated jacket; this is within the recommended temperature range for Nottingham Yeast.

I appreciate any thought you folks can throw my way! Thank you!

Attachments

Last edited: