You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Interesting German Brewing PDF

- Thread starter rabeb25

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

storunner13

Well-Known Member

SS Brewtech has a manometer integrated into their mash tun.

https://www.ssbrewtech.com/collections/mash-tuns/products/infussion-mash-tun-20-gal

Basically one sightglass above and one sightglass below the false bottom. If the pump is not running and not drawing negative pressure on the grain bed, the sightglasses will be at the same level. However, if you are running the pump and there is restriction (creating a vacuum below the false bottom) the sightglass below the false bottom will show a lower level of liquid. This will indicate that one needs to recirculate more slowly, or break up the grain bed to create a less-restricted flow.

https://www.ssbrewtech.com/collections/mash-tuns/products/infussion-mash-tun-20-gal

Basically one sightglass above and one sightglass below the false bottom. If the pump is not running and not drawing negative pressure on the grain bed, the sightglasses will be at the same level. However, if you are running the pump and there is restriction (creating a vacuum below the false bottom) the sightglass below the false bottom will show a lower level of liquid. This will indicate that one needs to recirculate more slowly, or break up the grain bed to create a less-restricted flow.

However, if you are running the pump and there is restriction (creating a vacuum below the false bottom) the sightglass below the false bottom will show a lower level of liquid. This will indicate that one needs to recirculate more slowly, or break up the grain bed to create a less-restricted flow.

Actually, if the sight glass is in the pump suction, the second you turn on the pump the level in the sight glass will drop because frictional pressure in the fittings and line length upstream of the sight glass. IMO, putting the sight glass in the pump suction makes it less effective because you never get a true level reading with there pump running.

^correct^ - much to the consternation of many who teed a sight tube to their drain port...

Cheers!

Cheers!

cyclonebeer

Well-Known Member

- Joined

- Nov 1, 2008

- Messages

- 112

- Reaction score

- 20

I'm new to the thread, and while I did read the attachment from the first post, I have not read all posts. I'm interested in doing a LoDo batch. I brew with an electric single vessel rig - mash in a mesh basket, recirculate, etc... What would be an appropriate dosage rate for SMB for a full volume mash with no sparge? Also, any tricks or tips for single vessel brewers? If this has already been discussed, feel free to refer me to post numbers in this thread. Thanks.

I'm new to the thread, and while I did read the attachment from the first post, I have not read all posts. I'm interested in doing a LoDo batch. I brew with an electric single vessel rig - mash in a mesh basket, recirculate, etc... What would be an appropriate dosage rate for SMB for a full volume mash with no sparge? Also, any tricks or tips for single vessel brewers? If this has already been discussed, feel free to refer me to post numbers in this thread. Thanks.

Short answer... much less than the PDF recommends. It's more likely in the 10-30ppm range than 100ppm range.

Long answer: This site has shown to not be friendly to low oxygen brewing. The conversation has moved to:

http://www.lowoxygenbrewing.com/forum/index.php

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

rabeb25

HE of who can not be spoken of.

Here is the most up to date, easy to follow instructions and resource there is:

http://www.lowoxygenbrewing.com/low-oxygen-methods/

http://www.lowoxygenbrewing.com/low-oxygen-methods/

Long answer: This site has shown to not be friendly to low oxygen brewing. We've moved the conversation to

http://www.lowoxygenbrewing.com/forum/index.php

I was wondering why this thread dried up. Thanks for posting the link.

The_Bishop

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 2,100

- Reaction score

- 676

Long answer: This site has shown to not be friendly to low oxygen brewing. We've moved the conversation to

I don't think that's true at all. This site is not friendly to sanctimonious, condescending comments about how "The holy grail of brewing has been found!" and "If you're not using this technique, your beer is horrible swill suitable only for cleaning drains!"

Any time anybody brought up questions about the process, or asked about some kind of testing to determine if there was any sort of actual improvement in the final product, there were dismissive comments made. Any time someone tried the process, and saw no difference or found problems they were chastised as, "You're doing it wrong."

In fact, some of your 'followers' have been warned about their attitude on the AHA forums, too.

That torpedoed the chances of a civilized 'LoDo' discussion.

SpeedYellow

Well-Known Member

Hmm. That LODO zealots are retreating to their online Jonestown may suggest that the house of cards is collapsing.

As someone who doesn't have a dog in this fight, what evidence are the non-believers looking for exactly other than fresher tasting beers that hold their flavor longer?

I have only recently starting trying some of the methods and find them to be useful even without the full-blown LoDo procedures. I can't imagine anybody is arguing that eliminating oxygen from the final product is a bad thing.

I have only recently starting trying some of the methods and find them to be useful even without the full-blown LoDo procedures. I can't imagine anybody is arguing that eliminating oxygen from the final product is a bad thing.

Big Monk

Trappist Please! 🍷

- Joined

- Dec 24, 2015

- Messages

- 2,192

- Reaction score

- 1,154

I don't think that's true at all. This site is not friendly to sanctimonious, condescending comments about how "The holy grail of brewing has been found!" and "If you're not using this technique, your beer is horrible swill suitable only for cleaning drains!"

Any time anybody brought up questions about the process, or asked about some kind of testing to determine if there was any sort of actual improvement in the final product, there were dismissive comments made. Any time someone tried the process, and saw no difference or found problems they were chastised as, "You're doing it wrong."

In fact, some of your 'followers' have been warned about their attitude on the AHA forums, too.

That torpedoed the chances of a civilized 'LoDo' discussion.

Hmm. That LODO zealots are retreating to their online Jonestown may suggest that the house of cards is collapsing.

Just to be clear: schematix didn't move any conversations anywhere. He is merely a registered member at the forum. He is not an administrator or even a moderator at our forum, nor is he a blog contributor. He does not speak for The Beerery or myself

The Beerery and I created our site out of a desire to offer a different, more nuanced and approachable look at the methods that The Beerery and the original GBF members proposed.

We are not affiliated with the German Brewing Forum. Our website has a ton of helpful information on it that we try and present in a positive light. Please feel free to check it out and reach out to one of us if you have any questions.

Our main paper can be found here:

http://www.lowoxygenbrewing.com/low-oxygen-methods/

The_Bishop

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 2,100

- Reaction score

- 676

Let me be clear: I think there's some technical merit to keeping dissolved oxygen low while brewing. I've switched a few things I used to do in order to limit oxygen ingress. I don't know that keeping it in the single pbb range is worth all the headache.

I haven't experienced some magical 'it' factor to be found from doing this. I just prefer the packaged beer stability. I just took offense to several LODO advocates saying that beer produced in a process different from theirs was 'swill'.

I haven't experienced some magical 'it' factor to be found from doing this. I just prefer the packaged beer stability. I just took offense to several LODO advocates saying that beer produced in a process different from theirs was 'swill'.

As someone who doesn't have a dog in this fight, what evidence exactly are the non-believers looking for other than fresher tasting beers that hold their flavor longer?

I have only recently starting trying some of the methods and find them to be useful even without the full-blown LoDo procedures. I can't imagine anybody is arguing that eliminating oxygen from the final product is a bad thing.

I think we are back to the "tone" of the paper and discussion thereafter. The creators of the low oxygen website would even agree that they may have missed on that. In addition, they have adjusted their guidance based on more data points to try and help people adapt it to their system. I imagine there is still going to be a significant investment (both time and money) that a brewer will need to consider to chase the full LODO effect. The recent trial on a single vessel BIAB demonstrated that it may not be sufficient to achieve LODO results. However, one could incorporate some of their recommendations and achieve some level of improvement. For instance, I find the cold-side spunding practices to be very beneficial.

The problem is that it takes something like a brulosophy experiment or a respected homebrewer to give it one try and determine it doesn't work for the rest of the community to deem it a myth (note that brulosophy left an open door to research further). The fact that it can be documented for breweries to monitor some level of DO throughout there process shows there is something to it. The question is how feasible is it for the average homebrewer to implement this process and replicate the results. I think that is the biggest challenge at this point. It would be great if we could all sample this beer and compare it to a regular process.

Let me be clear: I think there's some technical merit to keeping dissolved oxygen low while brewing. I've switched a few things I used to do in order to limit oxygen ingress. I don't know that keeping it in the single pbb range is worth all the headache.

I haven't experienced some magical 'it' factor to be found from doing this. I just prefer the packaged beer stability. I just took offense to several LODO advocates saying that beer produced in a process different from theirs was 'swill'.

Sounds like you and I are on the same page. I just take it for what its worth. Of course, just like anything in life, there's always going to be stupid stuff said on both sides of an argument so I don't focus on that too much.

It just seems like a silly topic for forums to be so divisive about.

rabeb25

HE of who can not be spoken of.

I haven't experienced some magical 'it' factor to be found from doing this. I just prefer the packaged beer stability. I just took offense to several LODO advocates saying that beer produced in a process different from theirs was 'swill'.

FWIW, I just recently put together an automated BIAB vessel to test out low oxygen methods compared to my main 3 vessel system that has been super tailored to it. In the hopes to shed light on all the folks who try this with single vessels.

Using ALL the methods outlined, I brewed the exact same beer I normally do using the main system. The malt flavor or 'IT" if you prefer went from about a 9 to about a 2. I attribute this due to the lowing of the bag into the strike water or dough in.. It definitely was not elegant and it made me have to break up doughballs and stir. This is one of the major factors of the loss of malt flavor. Malt flavor or "IT" is made (well really PRESERVED) in the mash tun. "IT" are natural antioxidants in the grains. It takes way to little to make it all but nothing. So its really an all or nothing venture, which sucks. For some it may be worth it, for others it may not be. Hot side is all about making (preserving "IT") and cold side is all about prolonging how long "IT" will be around. It's really as simple as that in nature. The wheres and the hows are the sticking points. It doesn't take much ( like less than a shot glass full of air) to muck this all up. So thats why the tight and stringent guidelines.

I really don't want this to turn into the poop slinging contest of before. Just trying to offer some insight ( from a guy with ~500 batches of low oxygen beer under his belt).

Prost

The_Bishop

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 2,100

- Reaction score

- 676

No sure I get the logic of that. My BIAB system, the last 'B' stands for 'Basket'. I slowly lower it into the kettle, and have no issues or doughballs. I'll gently swirl it with my mash paddle a time or two to ensure there's no dough balls, then the lid goes on and the recirculation starts. I'm usually in the 80% brewhouse range.

Maybe you're lowering the bag too quickly? Or maybe the bag keeps the grain compressed, limiting it's water uptake?

Maybe you're lowering the bag too quickly? Or maybe the bag keeps the grain compressed, limiting it's water uptake?

FWIW, I just recently put together an automated BIAB vessel to test out low oxygen methods compared to my main 3 vessel system that has been super tailored to it. In the hopes to shed light on all the folks who try this with single vessels.

Using ALL the methods outlined, I brewed the exact same beer I normally do using the main system. The malt flavor or 'IT" if you prefer went from about a 9 to about a 2. I attribute this due to the lowing of the bag into the strike water or dough in.. It definitely was not elegant and it made me have to break up doughballs and stir. This is one of the major factors of the loss of malt flavor. Malt flavor or "IT" is made (well really PRESERVED) in the mash tun. "IT" are natural antioxidants in the grains. It takes way to little to make it all but nothing. So its really an all or nothing venture, which sucks. For some it may be worth it, for others it may not be. Hot side is all about making (preserving "IT") and cold side is all about prolonging how long "IT" will be around. It's really as simple as that in nature. The wheres and the hows are the sticking points. It doesn't take much ( like less than a shot glass full of air) to muck this all up. So thats why the tight and stringent guidelines.

I really don't want this to turn into the poop slinging contest of before. Just trying to offer some insight ( from a guy with ~500 batches of low oxygen beer under his belt).

Prost

Something I'm playing with relative to BIAB is milling directly into my MT, dosed with SMB. I haven't been able to determine if this is a good idea or not yet, but it makes doughing in easy.

Here's a pic of the setup. Imagine a bag and a hopper full of grain.

View attachment 1501125840419.jpg

View attachment 1501125840419.jpg

FWIW, I just recently put together an automated BIAB vessel to test out low oxygen methods compared to my main 3 vessel system that has been super tailored to it. In the hopes to shed light on all the folks who try this with single vessels.

Hey rabeb. Did you measure either the Dissolved O2 or remaining sulphite after doughing in with BIAB? I do LODO BIAB and if you are going from a 9 to 2 on the flavour scale I might as well give up on the hot side of things. For what it is worth I noticed a difference between BIAB LODO and pre BIAB-LODO but who knows which step that is if the mashing-in is destroying the flavour.

Magnus314

Well-Known Member

My best "LODO-est" pilsner/Helles to date has been my normal BIAB with very little different on the hot side and near-perfect on the cold side.

rabeb25

HE of who can not be spoken of.

Hey rabeb. Did you measure either the Dissolved O2 or remaining sulphite after doughing in with BIAB? I do LODO BIAB and if you are going from a 9 to 2 on the flavour scale I might as well give up on the hot side of things. For what it is worth I noticed a difference between BIAB LODO and pre BIAB-LODO but who knows which step that is if the mashing-in is destroying the flavour.

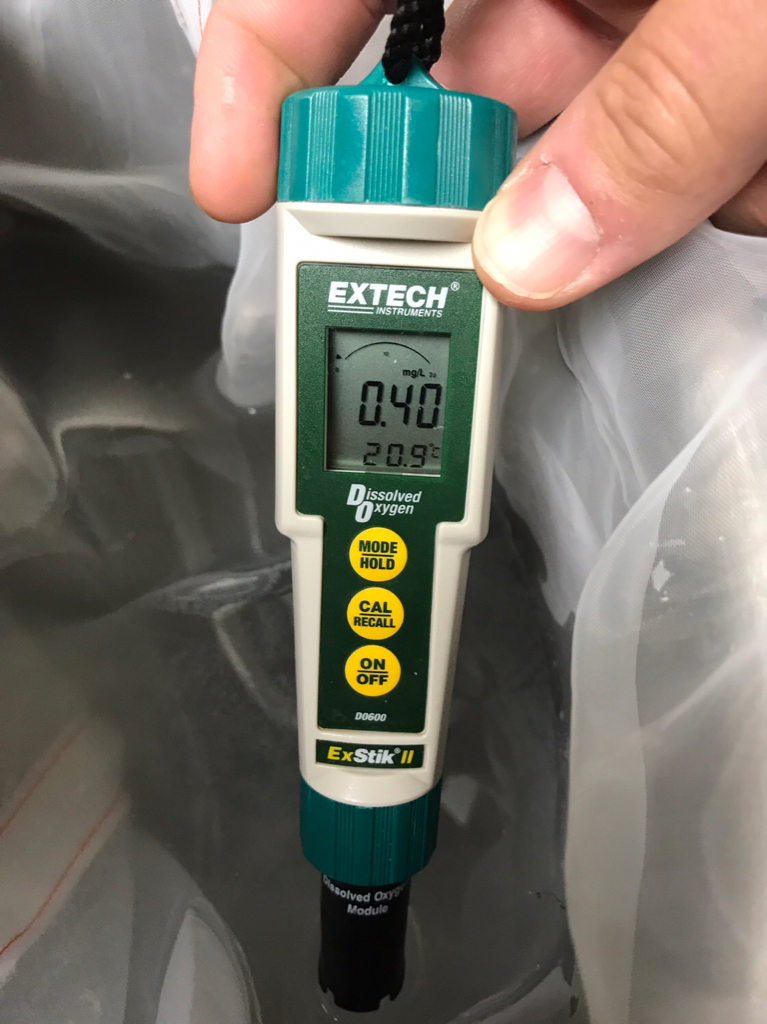

I did..

I brewed yesterday with some tests. Here is what I saw.

DO with yeast deoxygenation

DO after antioxidants

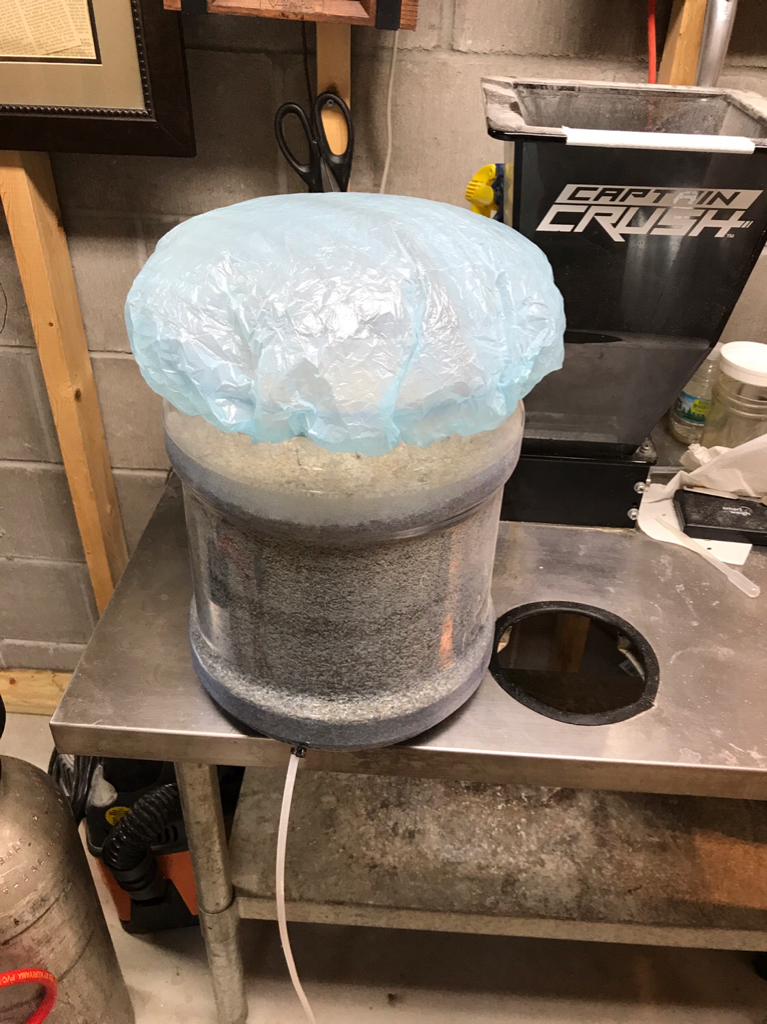

Purging grist with N2

Slow careful dough in with bag in place

After 5 minutes

That's as far as I got then the main system needed my attention. I carried out the rest of the batch. Malt flavor was lacking, but color was good. I tested my main batch and it never saw about .4 at all the steps. So there certainly is a easily double or triple the ingress with the single vessel. Other pics from the day

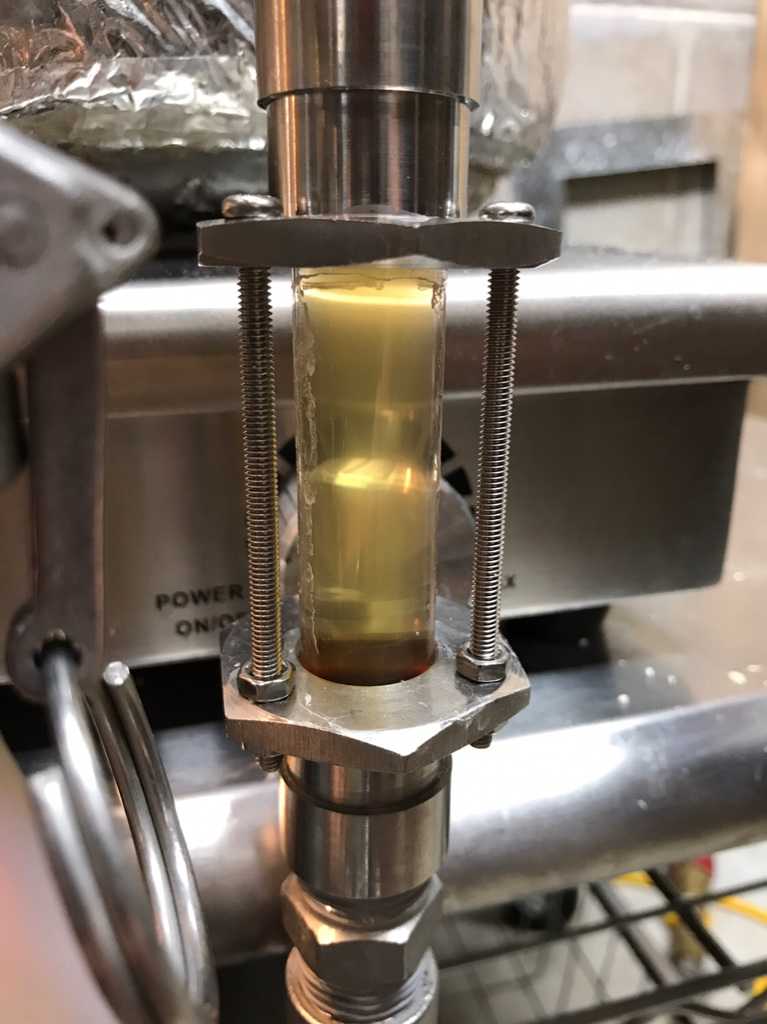

Mash clarity

Less crud (but I scooped again)

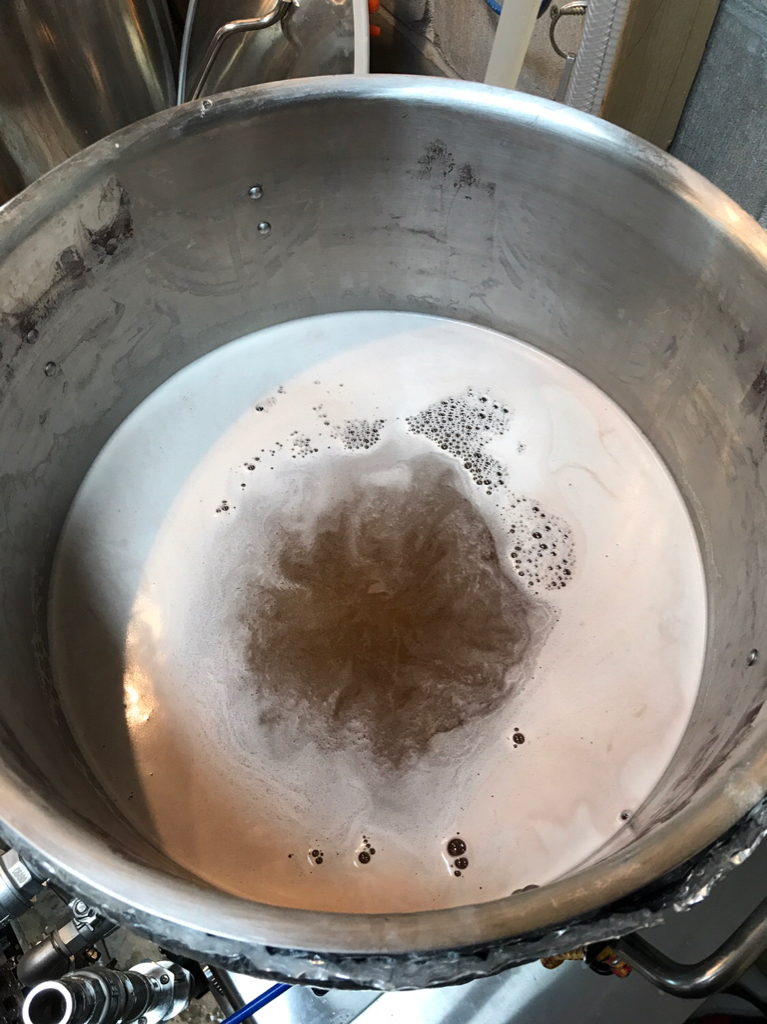

Break

Wort clarity into fermenter

The pale ale has a HINT of malt flavor, it's more doughy than anything, and it more bitter than normal. My guess is a combination of lack of malt flavor and maybe some herbestoffe notes as well. It's still a very nice "American" pale ale, but a far cry from what it normally is. I will update with the newest one here in a few days.

rabeb25

HE of who can not be spoken of.

My best "LODO-est" pilsner/Helles to date has been my normal BIAB with very little different on the hot side and near-perfect on the cold side.

I would say thats a fair assumption. Even with what I know about all this, every technique I try with BIAB seems to put me over the limits and the fresh lingering malt certainly suffers. Dough in is the biggest detriment to the whole process. In my main rig I add my grist to the mash tun, then purge the entire thing with N2 for over 10 minutes. Then I slowly fill from the bottom of the tun, and get very low DO levels, and the beer is bursting with fresh grain.

So many people now a days use BIAB, so I wanted to give it a fair shake and see how I can help folks get the most out of it.

Cavpilot2000

Well-Known Member

Bryan: I purge my mash tun with CO2 both before, during, and after milling (I mill directly into the CO@-filled mash tun). I push the CO2 through the bottom inlet, so when I run it for a minute or so after milling, it is pushing the CO2 up through the false bottom and grain bed before doughing in. Probably similar to your setup.In my main rig I add my grist to the mash tun, then purge the entire thing with N2 for over 10 minutes. Then I slowly fill from the bottom of the tun, and get very low DO levels, and the beer is bursting with fresh grain.

I considered switching to Nitrogen, but it would be a significant cost delta to both buy a nitrogen tank and keep it filled. Do you think there is a significant difference between using nitrogen and CO2?

rabeb25

HE of who can not be spoken of.

Bryan: I purge my mash tun with CO2 both before, during, and after milling (I mill directly into the CO@-filled mash tun). I push the CO2 through the bottom inlet, so when I run it for a minute or so after milling, it is pushing the CO2 up through the false bottom and grain bed before doughing in. Probably similar to your setup.

I considered switching to Nitrogen, but it would be a significant cost delta to both buy a nitrogen tank and keep it filled. Do you think there is a significant difference between using nitrogen and CO2?

Probably not, but N2 is more "safe" in regards to having large amounts in the air around you.

I have been easing into some of this - especially for my lagers. Hoping to piece together a better mash cap/sparge apparatus than the plastic lid and tubing I have been using...... Does anyone have a good set of components/instructions for a DIY mash cap??? Like to get that done this week.

Beyond that, something I have been playing with on my last few batches and am hoping to streamline is that I am now fermenting my lagers in 5 gallon kegs and spunding to carbonate. I move the wort from boil kettle to 5 gallon keg, make a slightly smaller batch than normal. Bent dip tube. I spund this keg toward the end. I have about 4.5 gallons in the keg with some head space for fermentation. Just seems like a lot better process in regard to moving the beer, racking, etc. I do end up with a bit less beer overall, but, it seems like it might be worth it so far.

Last batch I racked to 3 gallon keg after fermentation in 5 gallon keg, etc..... however, I had a gallon or a bit left in the primary keg..... I put it in the fridge and figured I would just drink some glasses off it so as not to let it go to waste - I was STUNNED by how good that beer was after about 4-5 weeks from brew day (Sitting on yeast/ferment) the entire time. Clear as glass, super fresh and crisp. I have no problem saying it was absolutely the best pilsner I have ever brewed in my life. I had the same beer on tap without any "LoDo" strategies and the "LoDo" one that I jumped to 3 gallon keg, and the "loDo" one that I left a gallon in the primary ferment keg - evaluation......

1.) Far and away the best one was the LoDo gallon left in the primary keg..... not even close.

2.) "The normal" one was very good.

3.) The LoDo one I jumped to the 3 gallon keg ended up with Diacetyl and I am trying to let that clean up at room temp. now..... we will see. Operator error on my part as I obviously took it off the yeast too soon.

I have a pilsner and Ofest going the same way right now. New plan is to leave it all in that primary longer and wait to jump it to 3 gallon keg until around 4 weeks (just really seemed to clean up so much better with a bit more time on the yeast.) I will then attempt to bottle the gallon or so that does not fit in my 3 gallon keg to see how that holds up.

I still have a ways to go in stream lining my own process, but with what I have done so far (mainly with helles/pilsner type beers) I am easily convinced that some of the strategies are really improving my beer.

Let's not go back to rehashing the past "he said" kind of stuff - Bryan and others have really provided a wealth of information that people can choose or not choose to use. I have had a variety of "dumb-noob" type questions that they have been gracious in answering. Overall, the discussion on these things has been way better lately than it was over the previous year - let's keep it going that way. There are absolutely some quality process strategies that can fit in to various levels of dedication and can fit various systems. I definitely appreciate the bits I have been able to take, even though I am not personally looking to completely overhaul my own system/methods at this time.

Beyond that, something I have been playing with on my last few batches and am hoping to streamline is that I am now fermenting my lagers in 5 gallon kegs and spunding to carbonate. I move the wort from boil kettle to 5 gallon keg, make a slightly smaller batch than normal. Bent dip tube. I spund this keg toward the end. I have about 4.5 gallons in the keg with some head space for fermentation. Just seems like a lot better process in regard to moving the beer, racking, etc. I do end up with a bit less beer overall, but, it seems like it might be worth it so far.

Last batch I racked to 3 gallon keg after fermentation in 5 gallon keg, etc..... however, I had a gallon or a bit left in the primary keg..... I put it in the fridge and figured I would just drink some glasses off it so as not to let it go to waste - I was STUNNED by how good that beer was after about 4-5 weeks from brew day (Sitting on yeast/ferment) the entire time. Clear as glass, super fresh and crisp. I have no problem saying it was absolutely the best pilsner I have ever brewed in my life. I had the same beer on tap without any "LoDo" strategies and the "LoDo" one that I jumped to 3 gallon keg, and the "loDo" one that I left a gallon in the primary ferment keg - evaluation......

1.) Far and away the best one was the LoDo gallon left in the primary keg..... not even close.

2.) "The normal" one was very good.

3.) The LoDo one I jumped to the 3 gallon keg ended up with Diacetyl and I am trying to let that clean up at room temp. now..... we will see. Operator error on my part as I obviously took it off the yeast too soon.

I have a pilsner and Ofest going the same way right now. New plan is to leave it all in that primary longer and wait to jump it to 3 gallon keg until around 4 weeks (just really seemed to clean up so much better with a bit more time on the yeast.) I will then attempt to bottle the gallon or so that does not fit in my 3 gallon keg to see how that holds up.

I still have a ways to go in stream lining my own process, but with what I have done so far (mainly with helles/pilsner type beers) I am easily convinced that some of the strategies are really improving my beer.

Let's not go back to rehashing the past "he said" kind of stuff - Bryan and others have really provided a wealth of information that people can choose or not choose to use. I have had a variety of "dumb-noob" type questions that they have been gracious in answering. Overall, the discussion on these things has been way better lately than it was over the previous year - let's keep it going that way. There are absolutely some quality process strategies that can fit in to various levels of dedication and can fit various systems. I definitely appreciate the bits I have been able to take, even though I am not personally looking to completely overhaul my own system/methods at this time.

Cavpilot2000

Well-Known Member

Probably not, but N2 is more "safe" in regards to having large amounts in the air around you.

I have choked myself once or twice sticking my head into an enclosed space that has become filled with CO2, but I'll risk it. ;-)

Similar threads

- Replies

- 5

- Views

- 1K

- Replies

- 3

- Views

- 702