MarTeBrew

Member

- Joined

- Mar 12, 2021

- Messages

- 11

- Reaction score

- 3

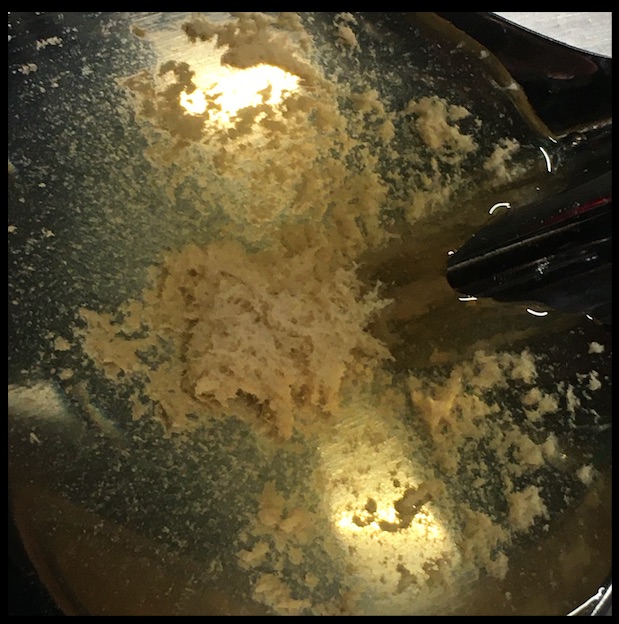

It was time to do a All-grain Sierra Nevada Pale Ale Clone on a new equipment

5-Gal HLT | 10-Gal MLT Thermos | 15-Gal Boil Kettle | pomp | plate chiller | for 5Gal of beer

After the initial dry run to measure losses and how temp was holding during hot water circulation, I adjusted BS3, and this is what happened:

1. I adjusted the water profile based on WARD H2O test with Beer Smith 3, adding salts and Lactic Acid to reduce my 7.9 pH ( I added 5ml instead 6.1ml as BS calculated, ending up with strike water 3.81 pH)

2. Mixed 11lb of grain with strike water based on temp calculation - not sure why yet because I preheated the thermos with 140F hot water - after 15 min of wort recirculation, I ended up with mash temp 140 F | the measured pH at that moment was 5.08

3. Due to that, I was not prepared for this mash temp hold for about 40 minutes, with temp around 140 F slowly rising.

4. To raise temp, I installed my HERMS coil and started warming the wort.

5. When I hit temp 149 F, my wort gravity was 1063.

6. When temp got to 156 F tried to adjust temp to 152 F, and I added (64 oz + 64 oz ->) a total of 1 Gal of cold water to reach temp 152 F

7. Around 90 min of the mashing process, the measured gravity indicated a drop to 1053

8. Prepared SPARGE water and started the process. After few minutes of sparging, the measured pH was 5.2 | so 1.1ml of Lactic Acid less + 1Gal of untreated water gave perfect pH

9. Sparge out was probably too quick because after around 30 min I ended up with wort at 1026 gravity points | 5.37 pH

10. Gladly, I had 3lb of DME and was able to bump gravity to 1050, not perfect, but this was the first run on this equipment.

11. Yeast were dancing on the Magnetic Stirrer for 24 hours, so there was a lot of puking for the next 36 hours from the carboy

If you would like to share your experience and tips on how to work with the new equipment, and how to adjust the fly mash / sparge process, your comments are welcome.

5-Gal HLT | 10-Gal MLT Thermos | 15-Gal Boil Kettle | pomp | plate chiller | for 5Gal of beer

After the initial dry run to measure losses and how temp was holding during hot water circulation, I adjusted BS3, and this is what happened:

1. I adjusted the water profile based on WARD H2O test with Beer Smith 3, adding salts and Lactic Acid to reduce my 7.9 pH ( I added 5ml instead 6.1ml as BS calculated, ending up with strike water 3.81 pH)

2. Mixed 11lb of grain with strike water based on temp calculation - not sure why yet because I preheated the thermos with 140F hot water - after 15 min of wort recirculation, I ended up with mash temp 140 F | the measured pH at that moment was 5.08

3. Due to that, I was not prepared for this mash temp hold for about 40 minutes, with temp around 140 F slowly rising.

4. To raise temp, I installed my HERMS coil and started warming the wort.

5. When I hit temp 149 F, my wort gravity was 1063.

6. When temp got to 156 F tried to adjust temp to 152 F, and I added (64 oz + 64 oz ->) a total of 1 Gal of cold water to reach temp 152 F

7. Around 90 min of the mashing process, the measured gravity indicated a drop to 1053

8. Prepared SPARGE water and started the process. After few minutes of sparging, the measured pH was 5.2 | so 1.1ml of Lactic Acid less + 1Gal of untreated water gave perfect pH

9. Sparge out was probably too quick because after around 30 min I ended up with wort at 1026 gravity points | 5.37 pH

10. Gladly, I had 3lb of DME and was able to bump gravity to 1050, not perfect, but this was the first run on this equipment.

11. Yeast were dancing on the Magnetic Stirrer for 24 hours, so there was a lot of puking for the next 36 hours from the carboy

If you would like to share your experience and tips on how to work with the new equipment, and how to adjust the fly mash / sparge process, your comments are welcome.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)