@RoyalGallon

Well-Known Member

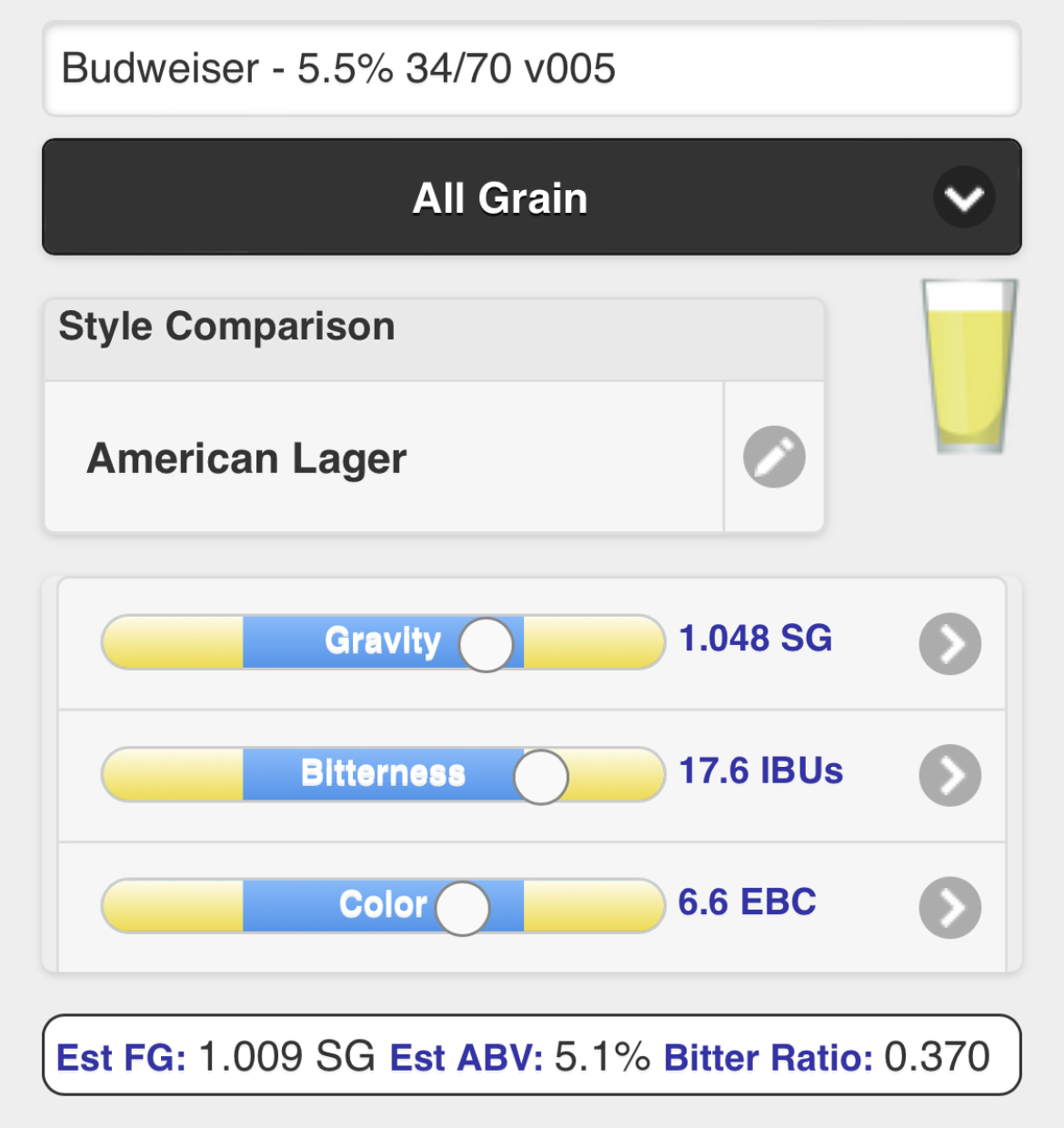

I’ve tried 3 times now to brew a really clean crisp American lager, but I’m really struggling with a fruity ester flavour instead of a clean nothingness from the yeast I want.

The obvious culprit is fermentation temperature however I’m happy that I have this controlled. I’ve been holding at 11C through the ferment in a glycol chilled Grainfather conical.

The second obvious culprit could be pitch rate. Here I’ve pitched a 34/70 starter of 3L into a 21L brew. This I’m less confident about.

What other areas would people recommend controlling or looking at to get rid of the esters?

The obvious culprit is fermentation temperature however I’m happy that I have this controlled. I’ve been holding at 11C through the ferment in a glycol chilled Grainfather conical.

The second obvious culprit could be pitch rate. Here I’ve pitched a 34/70 starter of 3L into a 21L brew. This I’m less confident about.

What other areas would people recommend controlling or looking at to get rid of the esters?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)