Shenanigans

Well-Known Member

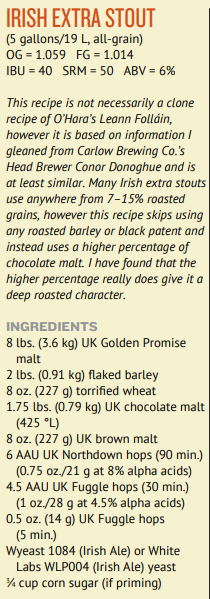

I brewed an Irish extra stout based on this last weekend:

https://byo.com/wp-content/uploads/woocommerce_uploads/Irish-Extra-Stout.pdf

I only discoverd on brew day that I didn't have enough Fuggles; the quantity in my Beersmith inventory was incorrect.

So I subbed it with some Challenger, which I like in a stout anyway.

My first time using WLP004 but with that grain bill I propabaly wouldn't even notice if I used US-05 or Nottingham instead.

https://byo.com/wp-content/uploads/woocommerce_uploads/Irish-Extra-Stout.pdf

I only discoverd on brew day that I didn't have enough Fuggles; the quantity in my Beersmith inventory was incorrect.

So I subbed it with some Challenger, which I like in a stout anyway.

My first time using WLP004 but with that grain bill I propabaly wouldn't even notice if I used US-05 or Nottingham instead.

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)