Anyone using that style probe put it straight into the wort?

In the process of making a thermowell and was just curious.

Doomsday said:Anyone using that style probe put it straight into the wort?

In the process of making a thermowell and was just curious.

BetterSense said:My thermowell is made out of a keg dip tube with the end soldered shut. Cost about $5.

Before that i used a racking cane with the end melted shut.

I built my controller and it's all set up and working correctly. I just brewed a beer and according to my thermometer it's at 70 degrees but the STC sensor taped to the side of my carboy is reading it at 64 degrees therefore making the flex watt heat tape come on and start heating. I need to ferment at 68 degrees so what does everyone do at the start of their fermentation? Do you set it at your target temp and let it sit? Should I trust the temp probe on the STC or should I adjust to what my thermometer is saying. How do I know if the controller temp probe is even correct or is this normal?

Got my kegerator wired up today. What settings are people using for kegerators/keezers?

You should check the STC-1000 in some ice water. If it's off, there's a calibration adjustment in the one of the menu settings. I'm pretty sure it's setting F4.

I just put the single stage in. I didn't realize the functions were different.

I did just what you suggested and it was 2.4 off so I adjusted it to read 0.0 and retaped the probe to the carboy and now it's reading the right temp. Thanks for the help!

BoomerHarley said:Does anybody have the instructions for the controller? I seem to have lost mine.

Why do you need 3? What are you doing with them?

That sounds a bit odd, based on STC-1000 feedback. I have not heard of anyone's probe being off by more than a few tenths, and that was after extending the probe (or dubious test methods).I did just what you suggested and it was 2.4 off so I adjusted it to read 0.0 and retaped the probe to the carboy and now it's reading the right temp. Thanks for the help!

That sounds a bit odd, based on STC-1000 feedback. I have not heard of anyone's probe being off by more than a few tenths, and that was after extending the probe (or dubious test methods).

Did you also test your thermometer when testing the sensor?

Are you properly insulating over the top of the sensor after affixing it to the wall of you ferm vessel?

That is off by a good bit. Mine are all within .2 or so with the ice water test, and too close to tell if it is really off. They also agreed with other therms at different temps.I tested it with 2 other thermometers that I own and known to be accurate and my neighbors thermometer as well and all of them had pretty much the same reading. I currently have the probe taped to a piece of foam I got from work then taped to the side of the carboy and holding temps really nice in my 5.0 cf chest freezer.

That is off by a good bit. Mine are all within .2 or so with the ice water test, and too close to tell if it is really off. They also agreed with other therms at different temps.

Next time it is out of service, you might check it at boiling to see how far off it is from that. If that is off by a good bit as well, the curve may be off enough to throw mid range temps off, unless you can accurately cal to 65F. If you want to replace it, the stainless probe version can be found for ~$3 each in multi packs, which can be handy if you add an audio jack QD. It does take a bit of digging to find a good price, and also to verify that the curve is the correct one.

There is plenty of info on the audio jacks- just a few posts up, I think. I would definitely want to toss that out of spec probe, if I made a QD setup for use with multiple probes. Having to adjust the cal, much less keep track of which probe is which, would be irritating.Do you have a link to this stainless probe and audio jack setup? I would like to check that out as well

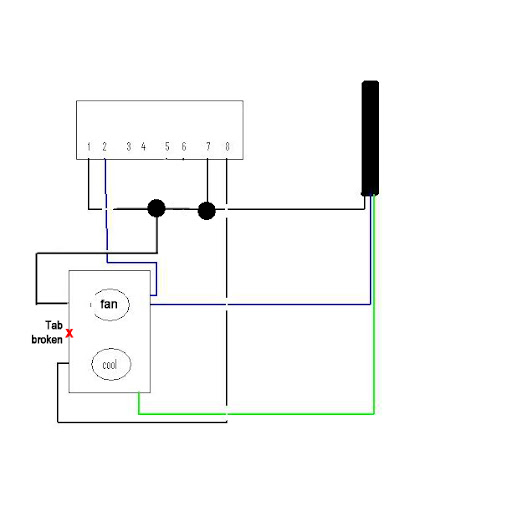

weeple2000 said:I have a stc-1000 that I will put in a project box with an outlet like in the first post. It will be used to control my keezer, however, and a fan. I would like the fan to only turn on when the compressor is running. So I want to only use the cooling function.

Do I still need to wire a hot outlet? Do I still follow the wiring diagram in the first post, or can I just wire 7 & 8 to the outlet and forget about 5 & 6?

What is your rationale for only running the fan when the compressor is running? This has been brought up many many times before. Run the fan the whole time, it works better, especially for a keezer.I have a stc-1000 that I will put in a project box with an outlet like in the first post. It will be used to control my keezer, however, and a fan. I would like the fan to only turn on when the compressor is running. So I want to only use the cooling function.

Do I still need to wire a hot outlet? Do I still follow the wiring diagram in the first post, or can I just wire 7 & 8 to the outlet and forget about 5 & 6?

Your description of how to accomplish the goal is only slightly less confusing than your reason for even having one.Yeah, that's exactly what I did. Skip 5&6. Wire the hot right into the hot side of the non-switched outlet. Break the tab on the hot side but not on neutral.

What is your rationale for only running the fan when the compressor is running? This has been brought up many many times before. Run the fan the whole time, it works better, especially for a keezer.

Your description of how to accomplish the goal is only slightly less confusing than your reason for even having one.

My snarky comment was more directed at the confusion over all the 'yes you need a hot outlet, just take the hot wire and wire it to the hot unswitched outlet and then break the tab on the hot one, but not the other', which was made even more confusing due to the fact that he specifically asked to have a second outlet switched to only come on when the compressor was on.That snark seems unnecessary. It's confusing as to why you would have a plug always hot to constantly run a fan when you are yourself advocating running a fan the whole time? I don't think it's confusing to just skip wiring 5&6 and just run a hot right into one of the two plugs in the outlet. Then that plug will always be on instead of being switched.

My snarky comment was more directed at the confusion over all the 'yes you need a hot outlet, just take the hot wire and wire it to the hot unswitched outlet and then break the tab on the hot one, but not the other', which was made even more confusing due to the fact that he specifically asked to have a second outlet switched to only come on when the compressor was on.

Although I am still confused, unless you meant "wouldn't" in your opening statement.

RE: wiring. I feel a more practical/versatile way to configure it, if you are only using a single duplex outlet, is to have a heating outlet and a cooling outlet. An 'always on' outlet is usually close by, especially when using the controller. Some add a second duplex outlet that is 'always on'.

I don't know why many peoples first instinct is to want to have their fan switched with the cooling/heating, especially when a critical time to have the fan on is just after cooling has shut off. A fan is also needed when cooling has been off for a long time to prevent stratification in a keezer, which causes your shanks/faucets to heat up and cause foaming.