Oxebar disconnects are very sensitive. If you put something in your keezer and it puts pressure on the gas line or disconnect, it can very quickly empty a 20lb CO2 canister by leaking out. DON'T DO THAT!!!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Don't Do That.

- Thread starter TAK

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

beren

Well-Known Member

Bleach plus acid, like vinegar. I think it’s 2tbsp of each in 5 gal water will kill almost anything. There was an interview with one of the people who designed starsan and I believe he called it a “stone cold killer”If it's truly mold, you can knock it down with about :30 seconds of contact time with Clorox bleach, followed by a thorough rinsing, boiling (in fresh water), soaking in PBW, another thorough rinse, capped off with a StarSan soak.

It works wonders. So I'm told. Don't ask.

shoengine

Whale Noun Member

That interview was on Basic Brewing Radio I believe. Love that podcast.Bleach plus acid, like vinegar. I think it’s 2tbsp of each in 5 gal water will kill almost anything. There was an interview with one of the people who designed starsan and I believe he called it a “stone cold killer”

So yesterday I decided to brew again (Trying to get one last one in before Mother's Day) and everything went great. No open valves, no messes, efficiency and volumes were on the dot.

Racked to the fermentor and pitched the kveik yeast at about 87° F. Hooked up the chiller and flipped off the lights, but waited around for the 120 seconds or so for the pump to turn on.

Which is a very, very good thing.

Lights are off, pump turns on and for the first second or so everything sounds fine. Then a spraying sound. I'm more used to the sound of liquid through a hose, which is muted, and really had no splashing noises. Very concerned, I flipped the lights on and just a hair above the hose barb on the inlet side of the coil is a tear almost the diameter of the hose and it is just dumping coolant. I quickly switched off the pump, found the tear and just cut it off above the tear and got it back on and cooling.

This just reinforces the habit of not assuming something will work as it always had. If I had walked out before it turned on, I would have 4.5 gallons of glycol and water on the floor and two dead pumps. Who knows, the chiller might've died too, trying to chill the ambient air to 40°.

One of my favorite sayings conveyed to me by an elderly gentleman decades ago is simply;

“There’s no education in the second kick of a mule!”

For those of you unfamiliar with Southern agricultural logic, it simply means that if you make the same stupid mistake again, (like walking up quietly behind a mule and surprising him), you can expect the same undesirable result as the first time, so there’s nothing new to learn in the second occasion that you didn’t learn in the first. However, some of us numbskulls seem to never learn!

I wanted to try adding gelatin to my keg and see if I can get a little cleaner beer. It’s never been a big deal to me since I typically drink dark stouts in a ceramic mug through the winter, and I often put my blonde ales in a thermal mug in the summer. But I did end up with an exceptionally clear beer back in the fall and decided that if I could replicate it without too much effort, it would be nice.

I had already injected priming sugar and ascorbic acid through the gas post back several weeks ago when I kegged this batch. I had checked the pressure and found that it had pegged the needle on my spunding valve as I moved it to the kegerator. I left it in there for a couple days to cool down thoroughly before adding the gelatin.

Today, I prepared my gelatin and drew it up into the large syringe and attached my ball lock connector. Now here’s where I went off course. This is the first time I’ve ever tried to inject anything into a keg that is already in the kegerator. I had to navigate the two kegs and two tanks and their associated lines to gain access to the gas post on my target keg. Once I had snaked it in their, I just popped it on. Did I pull the PRV to relieve the keg pressure first?? NO! Did I keep my hand on the back end of the plunger as I promised myself that I would always do?? NO!

So, as you may have guessed, I got kicked again! Yes that wonderful warm sticky shower as the plunger and all the contents of the syringe leave the back end of the syringe at high speed.

Yes that wonderful warm sticky shower as the plunger and all the contents of the syringe leave the back end of the syringe at high speed.

Maybe, just maybe, it takes me two kicks after all.

“There’s no education in the second kick of a mule!”

For those of you unfamiliar with Southern agricultural logic, it simply means that if you make the same stupid mistake again, (like walking up quietly behind a mule and surprising him), you can expect the same undesirable result as the first time, so there’s nothing new to learn in the second occasion that you didn’t learn in the first. However, some of us numbskulls seem to never learn!

I wanted to try adding gelatin to my keg and see if I can get a little cleaner beer. It’s never been a big deal to me since I typically drink dark stouts in a ceramic mug through the winter, and I often put my blonde ales in a thermal mug in the summer. But I did end up with an exceptionally clear beer back in the fall and decided that if I could replicate it without too much effort, it would be nice.

I had already injected priming sugar and ascorbic acid through the gas post back several weeks ago when I kegged this batch. I had checked the pressure and found that it had pegged the needle on my spunding valve as I moved it to the kegerator. I left it in there for a couple days to cool down thoroughly before adding the gelatin.

Today, I prepared my gelatin and drew it up into the large syringe and attached my ball lock connector. Now here’s where I went off course. This is the first time I’ve ever tried to inject anything into a keg that is already in the kegerator. I had to navigate the two kegs and two tanks and their associated lines to gain access to the gas post on my target keg. Once I had snaked it in their, I just popped it on. Did I pull the PRV to relieve the keg pressure first?? NO! Did I keep my hand on the back end of the plunger as I promised myself that I would always do?? NO!

So, as you may have guessed, I got kicked again!

Maybe, just maybe, it takes me two kicks after all.

Last edited:

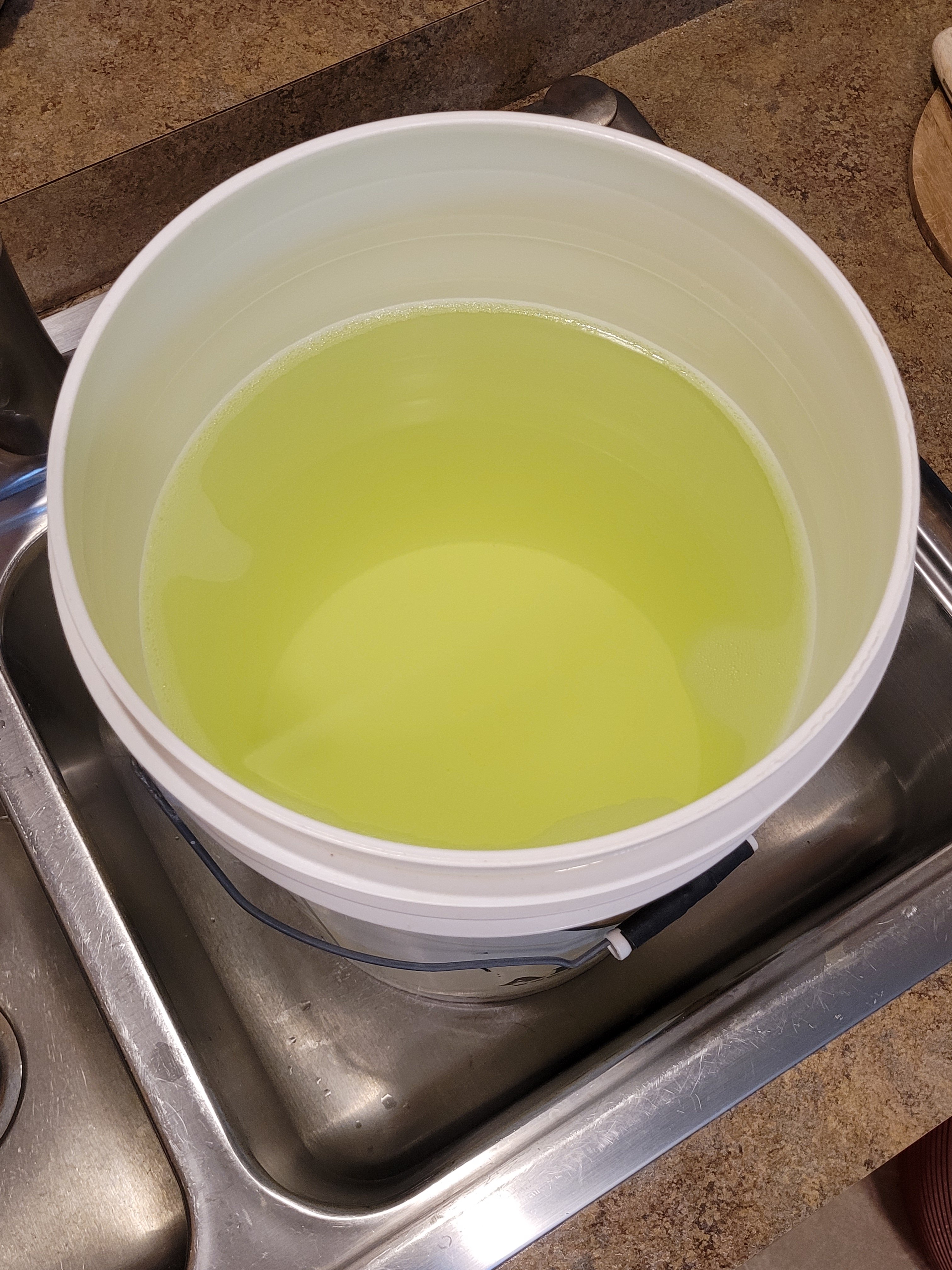

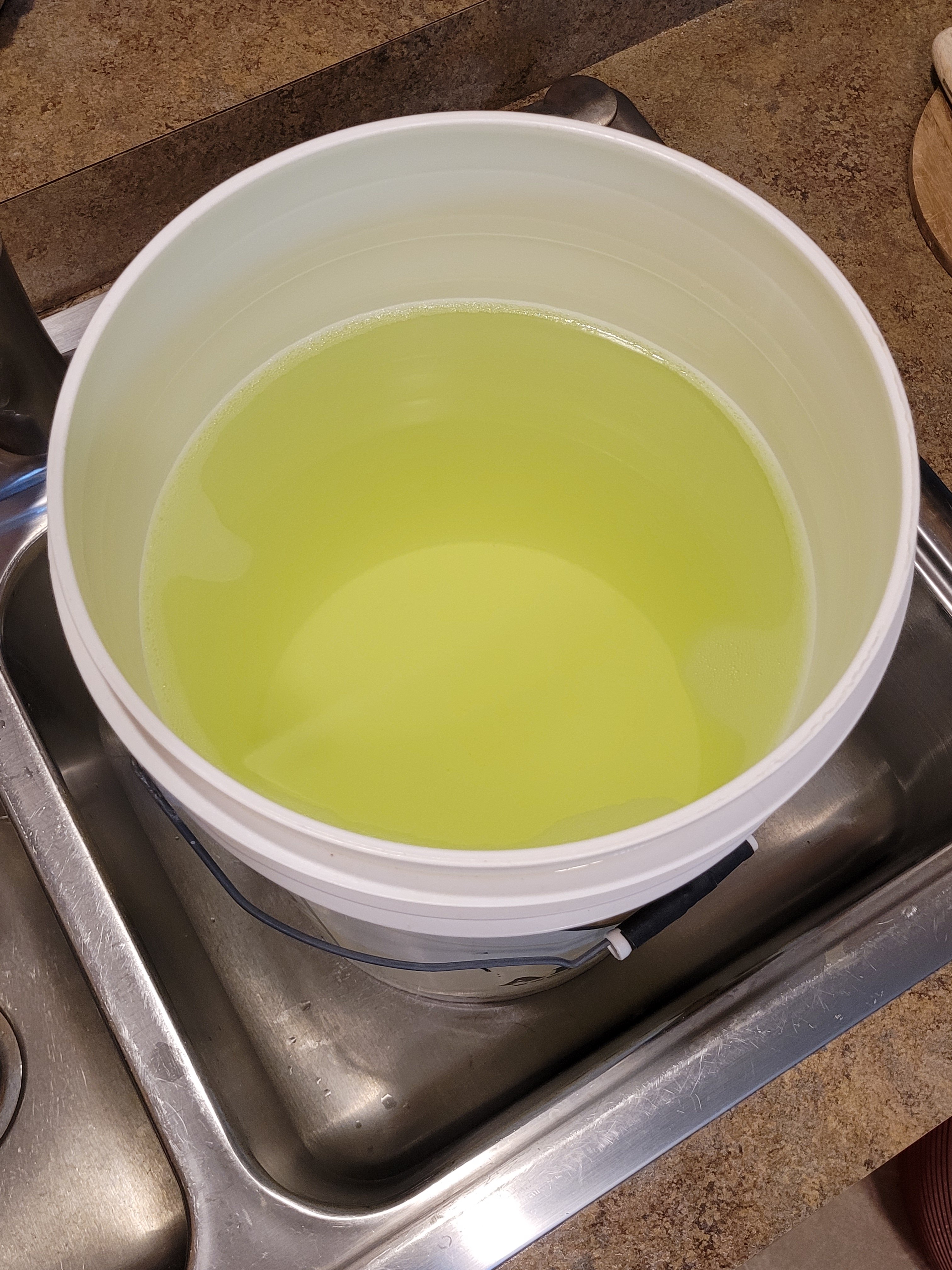

Don't put anything copper in your batch of Starsan. I wasn't thinking today and put my copper tubing diy carboy siphon thingy that I use once in a bazillion years into the bucket of Starsan I just mixed up. A bucket normally lasts me a long time, but not this one. Down the drain it went. I really didn't want to dunk my bottles in that grasshopper green stew of copper salts, so the quart spray bottle was the stand-in for bottle sanitation.

I really didn't want to dunk my bottles in that grasshopper green stew of copper salts, so the quart spray bottle was the stand-in for bottle sanitation.

Do the Dew!

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$33.98

DYKWSWYX Heavy Duty Brewing Gloves (1 Pair) - 55CM Long Chemical Resistant Plastic Gloves for Beer & Wine Making, Cleaning, Homebrew Equipment Protection

wuhanshijiayangzhiyimaoyiyouxiangongsi

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

Are you sure your dog didn’t walk by and lift a leg in that direction when you weren’t looking?Don't put anything copper in your batch of Starsan. I wasn't thinking today and put my copper tubing diy carboy siphon thingy that I use once in a bazillion years into the bucket of Starsan I just mixed up. A bucket normally lasts me a long time, but not this one. Down the drain it went. I really didn't want to dunk my bottles in that grasshopper green stew of copper salts, so the quart spray bottle was the stand-in for bottle sanitation.

View attachment 877020

Made a small batch of cider so didn't label bottles just made my notes and stuck them in the six pack holder I put the cider in. Spotted one a couple of days ago, notes and holder missing. I really like it and have no idea what I did to it or how old it is to be able replicate it. Don't do that.

Don't do that.

Sounds like - "you're gelling". Thought that was a good thing.One of my favorite sayings conveyed to me by an elderly gentleman decades ago is simply;

“There’s no education in the second kick of a mule!”

For those of you unfamiliar with Southern agricultural logic, it simply means that if you make the same stupid mistake again, (like walking up quietly behind a mule and surprising him), you can expect the same undesirable result as the first time, so there’s nothing new to learn in the second occasion that you didn’t learn in the first. However, some of us numbskulls seem to never learn!

I wanted to try adding gelatin to my keg and see if I can get a little cleaner beer. It’s never been a big deal to me since I typically drink dark stouts in a ceramic mug through the winter, and I often put my blonde ales in a thermal mug in the summer. But I did end up with an exceptionally clear beer back in the fall and decided that if I could replicate it without too much effort, it would be nice.

I had already injected priming sugar and ascorbic acid through the gas post back several weeks ago when I kegged this batch. I had checked the pressure and found that it had pegged the needle on my spunding valve as I moved it to the kegerator. I left it in there for a couple days to cool down thoroughly before adding the gelatin.

Today, I prepared my gelatin and drew it up into the large syringe and attached my ball lock connector. Now here’s where I went off course. This is the first time I’ve ever tried to inject anything into a keg that is already in the kegerator. I had to navigate the two kegs and two tanks and their associated lines to gain access to the gas post on my target keg. Once I had snaked it in their, I just popped it on. Did I pull the PRV to relieve the keg pressure first?? NO! Did I keep my hand on the back end of the plunger as I promised myself that I would always do?? NO!

So, as you may have guessed, I got kicked again!Yes that wonderful warm sticky shower as the plunger and all the contents of the syringe leave the back end of the syringe at high speed.

Maybe, just maybe, it takes me two kicks after all.

Sounds like - "you're gelling". Thought that was a good thing.

Snuffy

He ain't scared.

- Joined

- Nov 5, 2019

- Messages

- 1,904

- Reaction score

- 3,058

Mystery Brew!Made a small batch of cider so didn't label bottles just made my notes and stuck them in the six pack holder I put the cider in. Spotted one a couple of days ago, notes and holder missing. I really like it and have no idea what I did to it or how old it is to be able replicate it.Don't do that.

View attachment 877490

They said "when you rack your wine, don't leave headspace."

Fine then.

I won't.

Fine then.

I won't.

- Joined

- Nov 26, 2013

- Messages

- 9,915

- Reaction score

- 24,067

They said "when you rack your wine, don't leave headspace."

Fine then.

I won't.

View attachment 877514

I would have drop cloths on the floor if I ever did that.

And the walls.

And the ceiling.

Would that make them Lift Cloths?

That would make them "Reasonable Preparations" which explains why I don't have any.I would have drop cloths on the floor if I ever did that.

And the walls.

And the ceiling.

Would that make them Lift Cloths?

Fortunately, SWMBO has found my ceiling and wall cleaning abilities to be sufficiently acceptable that I'm allowed to continue making questionable life choices.

- Joined

- Nov 26, 2013

- Messages

- 9,915

- Reaction score

- 24,067

Dear Sufficient Cleaner,my ceiling and wall cleaning abilities to be sufficiently acceptable

I hate you.

Sincerely,

Banished to the basement and the garage.

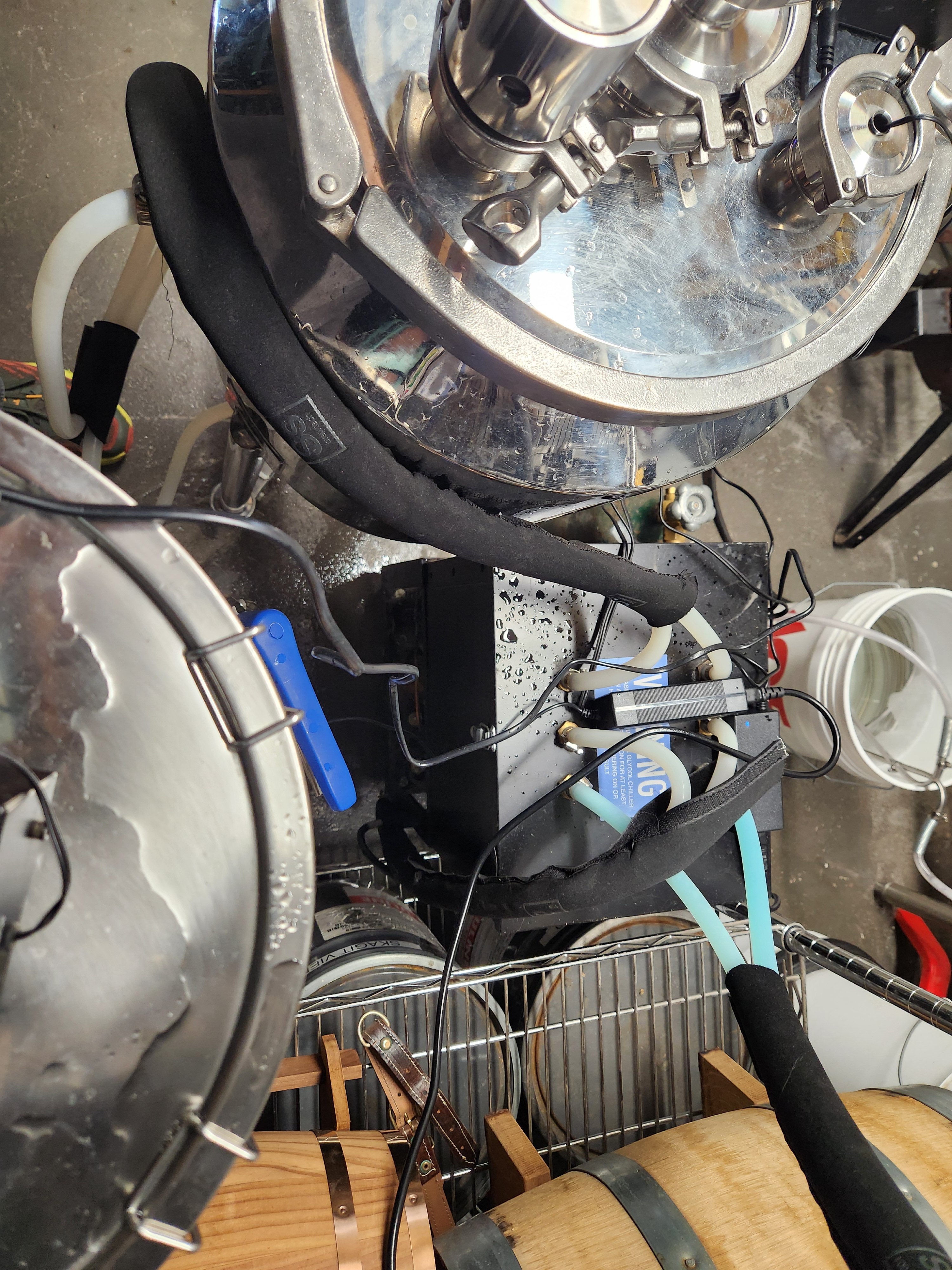

Don't start the 1/5 hp 1560 gpm submersible pump in your high tech keg washer without a keg present.

Looks like that spray ball really works dandy...Don't start the 1/5 hp 1560 gpm submersible pump in your high tech keg washer without a keg present.

<Ugh!>

crazyjake19

Well-Known Member

My latest "don't do that"... Don't make a starter of Wy1318 larger than 2L in a 4L flask. A 2.5L starter climbed right up and out of that and made a huge mess of my stir plate.

I've never had WY1318 climb up the walls like you're describing. But I've always been adding a drop of Fermcap-S per 1.5-1.8 liter starter when boiling. That seems to keep foaming down well enough.My latest "don't do that"... Don't make a starter of Wy1318 larger than 2L in a 4L flask. A 2.5L starter climbed right up and out of that and made a huge mess of my stir plate.

And the starters are always kept at room temps, around 72-74°F, rarely much higher.

I typically do 5 liter "overbuild" starters in a 5 liter e-flask when using 1318 and always put four drops of Fermcap in before putting it on the stir plate...

Cheers!

Cheers!

crazyjake19

Well-Known Member

I've never found a need to use Fermcap with anything else, but I might have to keep some on hand for large 1318 starters from now on. And my starters are always at 67-70ºF in the brew room, never higher.I've never had WY1318 climb up the walls like you're describing. But I've always been adding a drop of Fermcap-S per 1.5-1.8 liter starter when boiling. That seems to keep foaming down well enough.

And the starters are always kept at room temps, around 72-74°F, rarely much higher.

I left my pot of starter wort in the sink, bathed in cool water to chill while we ate dinner. My lady told my son to rinse his plate. I came back to a pot sitting in a sink full of cloudy water and not sure if some may have seeped into my pot.

Don’t do that.

Don’t do that.

Last edited:

Lampy

Well-Known Member

Sad! I share kitchen space with other adults and my kids, but I use the sink for wort chilling. I have started covering up the pot with not only a lid, but also plastic wrap or a plastic grocery bag.I left my pot of starter wort in the sink, bathed in cool water to chill while we ate dinner. My lady told my son to rinse his plate. I came back to a pot sitting in a sink full of cloudy water and not sure if some may have seeped into my pot.

Don’t do that.

- Joined

- Oct 12, 2020

- Messages

- 3,535

- Reaction score

- 6,773

Your son will grow up to be a Voter (if such a thing still exists then). This is a perfect learning opportunity: Next time you brew, include your son so that he can learn that there is much more to the world than that which is immediately obvious and often what we innocently do can have dire consequences we lacked the knowledge to forsee....Or: Install locked doors at brew-time and allow your son to grow up in blissful ignorance.I left my pot of starter wort in the sink, bathed in cool water to chill while we ate dinner. My lady told my son to rinse his plate. I came back to a pot sitting in a sink full of cloudy water and not sure if some may have seeped into my pot.

Don’t do that.

Follow me for more parenting advice!

(I don't have kids, but I do have to create barricades for my cat.)

Don't forget to relieve pressure from your conical before dumping trub when getting ready to clean it.. in my defense I had kegged before I left for vacation last week, decided to brew yesterday, so it sat for a week with co2 in it from the closed transfer... well, 8psi plus a pound or 2 of leftover dry hops equals my wife shaking her head and my dad laughing.. not the first time I was covered in hop sludge, but this one was a pretty good dosing, luckily I wear glasses haha.

Don't do that.

Don't do that.

Not ashamed to say I've done similar with a Fermzilla collection jar under 10PSI. It's amazing just how much hop matter can be forced out of a slightly unscrewed gasket sealed threaded joint.

Over the weekend, I decided to make a gallon of starter wort and can it in my pressure cooker for future use. Everything was going fine until the pressure cooker heated up and started leaking steam out of the overpressure relief plug. Having never paid much attention to the plug, I assumed that pushing down on it with an oven mitt on might seal it. What I didn't understand was that it is just a rubber plug that is inserted from the underside of the lid. So, when I pushed down on it, the plug fell into the pressure cooker with a blast of steam erupting from the now open hole in the lid. Obviously, I had to shut off the heat immediately.

Not wanting to waste a gallon of wort waiting to be canned, I jumped on Amazon, found replacement plugs and paid extra for overnight delivery first thing the following morning. Based on some quick Google research, it appeared that everything should be okay as long as I canned the jars within 24 hours of my first attempt.

The next morning, my Amazon shipment did not arrive. Now what? I then realized from my Amazon order that the overpressure plugs are just rubber plugs. So how could the original plug have failed in the first place?

It then dawned on me that by pushing down on the original plug I probably pushed it out of the hole, and it was probably sitting inside the pressure cooker intact. It was! I simply pushed it back into the lid from the underside and proceeded to can the wort without issue. Of course, the new plugs were delivered shortly after I finished canning the wort. I now have 4 replacement overpressure plugs that I will never need or will probably lose before I need one.

Not wanting to waste a gallon of wort waiting to be canned, I jumped on Amazon, found replacement plugs and paid extra for overnight delivery first thing the following morning. Based on some quick Google research, it appeared that everything should be okay as long as I canned the jars within 24 hours of my first attempt.

The next morning, my Amazon shipment did not arrive. Now what? I then realized from my Amazon order that the overpressure plugs are just rubber plugs. So how could the original plug have failed in the first place?

It then dawned on me that by pushing down on the original plug I probably pushed it out of the hole, and it was probably sitting inside the pressure cooker intact. It was! I simply pushed it back into the lid from the underside and proceeded to can the wort without issue. Of course, the new plugs were delivered shortly after I finished canning the wort. I now have 4 replacement overpressure plugs that I will never need or will probably lose before I need one.

Last edited:

Keep the extra plugs handy. They rarely fail, but if a mouse gets into the area where you keep your canning gear, it’s about the only thing on a pressure cooker he can chew on; and chew he will. I had to order a replacement plug a few years back when this happened to me.I now have 4 replacement overpressure plugs that I will never need or will probably lose before I need one.

- Joined

- Nov 26, 2013

- Messages

- 9,915

- Reaction score

- 24,067

You **will** keep those plugs.

Years from now, not today, not tomorrow, but none too soon somewhere in the rest of your life, you will come across them and have **NO** idea what they are, where they are used, what they are for.

Ask me how I know. Or rather, don't know.

Years from now, not today, not tomorrow, but none too soon somewhere in the rest of your life, you will come across them and have **NO** idea what they are, where they are used, what they are for.

Ask me how I know. Or rather, don't know.

Been there; done that! I now write on the packaging specifically what such things are for.You **will** keep those plugs.

Years from now, not today, not tomorrow, but none too soon somewhere in the rest of your life, you will come across them and have **NO** idea what they are, where they are used, what they are for.

Ask me how I know. Or rather, don't know.

Also, if you have an Ace/True Value style hardware store near by, they carry pressure cooker gaskets and plugs on the shelf.

Or take advantage of Amazon’s usual 30 day free return policy.Over the weekend, I decided to make a gallon of starter wort and can it in my pressure cooker for future use. Everything was going fine until the pressure cooker heated up and started leaking steam out of the overpressure relief plug. Having never paid much attention to the plug, I assumed that pushing down on it with an oven mitt on might seal it. What I didn't understand was that it is just a rubber plug that is inserted from the underside of the lid. So, when I pushed down on it, the plug fell into the pressure cooker with a blast of steam erupting from the now open hole in the lid. Obviously, I had to shut off the heat immediately.

Not wanting to waste a gallon of wort waiting to be canned, I jumped on Amazon, found replacement plugs and paid extra for overnight delivery first thing the following morning. Based on some quick Google research, it appeared that everything should be okay as long as I canned the jars within 24 hours of my first attempt.

The next morning, my Amazon shipment did not arrive. Now what? I then realized from my Amazon order that the overpressure plugs are just rubber plugs. So how could the original plug have failed in the first place?

View attachment 880409

It then dawned on me that by pushing down on the original plug I probably pushed it out of the hole, and it was probably sitting inside the pressure cooker intact. It was! I simply pushed it back into the lid from the underside and proceeded to can the wort without issue. Of course, the new plugs were delivered shortly after I finished canning the wort. I now have 4 replacement overpressure plugs that I will never need or will probably lose before I need one.

I envy you guys who have inhuman organizational skills, where everything is always in its place. At any one time I have one or two buckets in my garage containing random brewery parts, needing to be sorted into their correct homes. This almost never happens. The only small piece of equipment that ALWAYS goes where it belongs is the string loop I use to hoist the wilser bag after the mash; I've misplaced it too many times to count and don't have an extra handy. Twice I've had to fish it out from the yard waste bin after dumping spent grain. Yes, I could buy a roll of heavy nylon cord and make some extras, but that would require leaving the house.

I agree. In my world everything is in its place. The problem is its place is where it currently resides and I often don’t know where that is…. Until I buy a new one and go to put it away, in the same place I misplaced the old one.I envy you guys who have inhuman organizational skills, where everything is always in its place. At any one time I have one or two buckets in my garage containing random brewery parts, needing to be sorted into their correct homes. This almost never happens. The only small piece of equipment that ALWAYS goes where it belongs is the string loop I use to hoist the wilser bag after the mash; I've misplaced it too many times to count and don't have an extra handy. Twice I've had to fish it out from the yard waste bin after dumping spent grain. Yes, I could buy a roll of heavy nylon cord and make some extras, but that would require leaving the house.

Yes. Everything is always in its place. It's just that I usually can't remember where that place is.where everything is always in its place

And I thought I was the only one......

- Joined

- Nov 26, 2013

- Messages

- 9,915

- Reaction score

- 24,067

I still succumb to "I'll set this here. It's the right place for it. It'll be there in the right place when I need to remember where it is because that place is the place where I'll remember that it's there and where it is and what it's for.

Nope.

Nope.

Like the bittering hops, " I'll set these here so I don't forget to add them."

It certainly makes brewing a challenge.

Similar threads

- Replies

- 21

- Views

- 1K

- Replies

- 17

- Views

- 2K

- Replies

- 66

- Views

- 2K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)