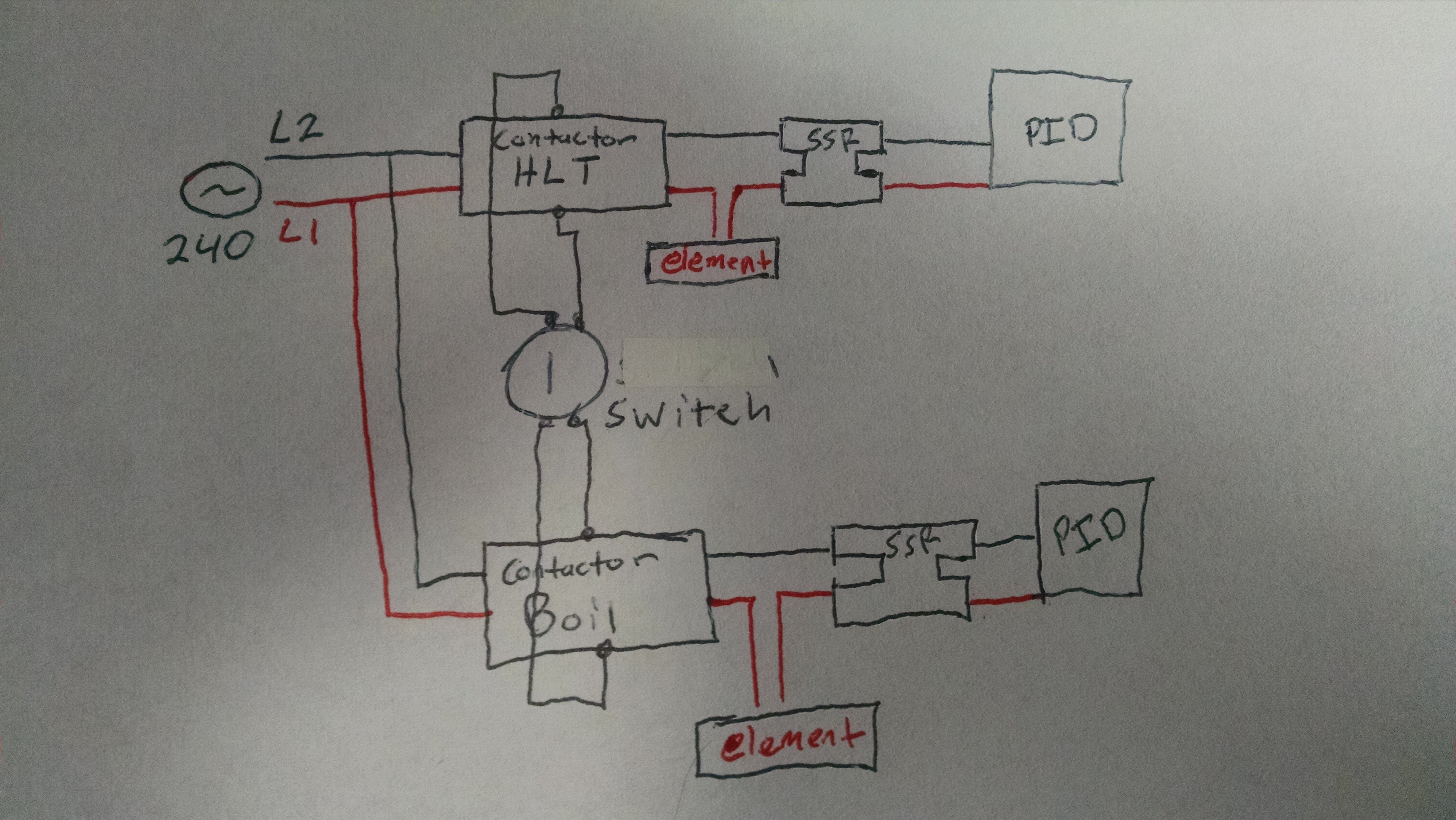

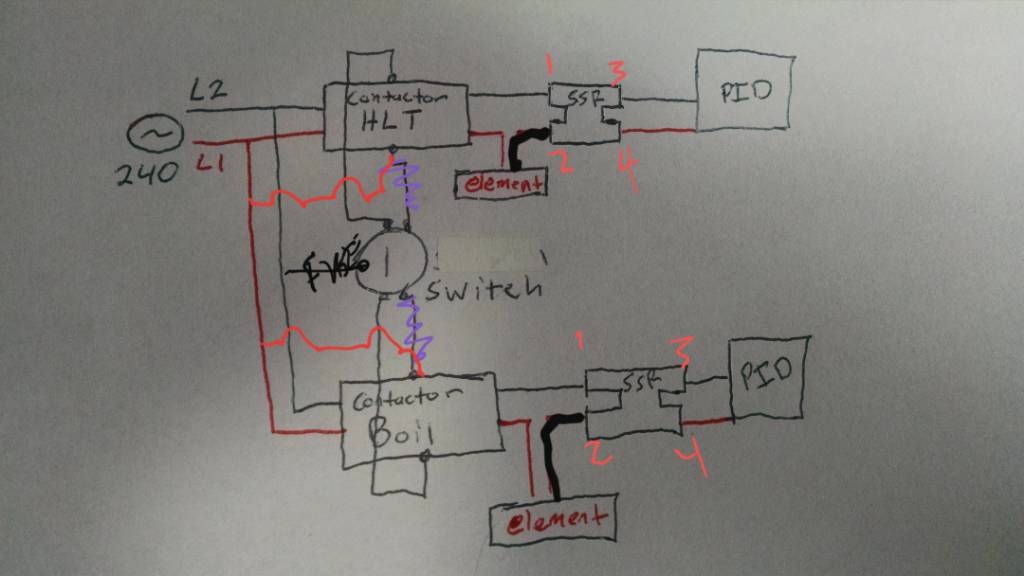

The contactor is a mechanical isolation of both L1 AND L2 from the element. The SSR is using a pulse width signal from the controller to effectively transition the element from 110V to 240V at a rate that the controller decides by switching only one leg, L1 or L2. ...

I don't believe the statement about transitioning the element voltage between 110 volts and 240 volts is accurate for the majority of electric systems.

In order to switch the element voltage between 120 and 240 volts, you would need another switch to connect one side of the element between the L2 and the neutral while keeping the other side of the element connected to L1.

For most electric systems using a controller, the typical practice is to switch the element between the full 240 VAC and 0 VAC (off).

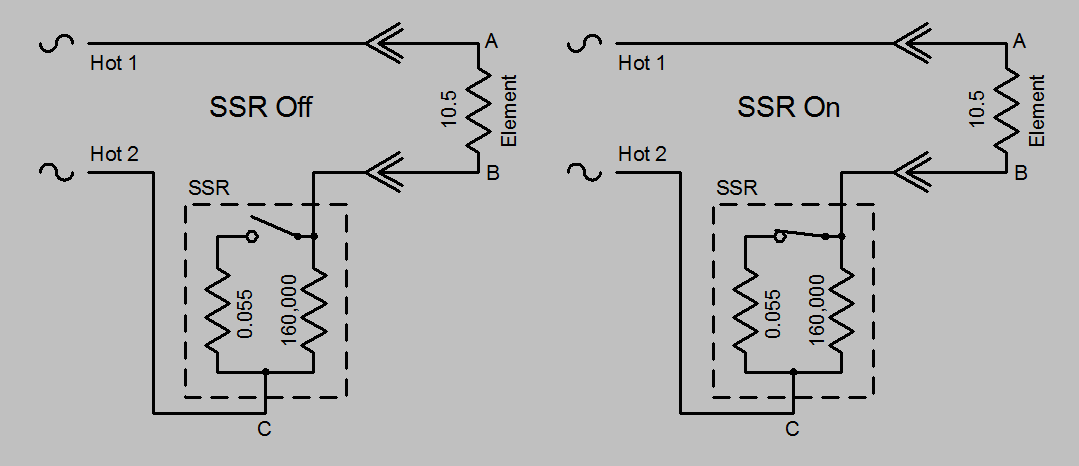

SSR behavior is widely misunderstood. An SSR is not a voltage switch, but rather a current modulator that doesn't eliminate current flow when off, but rather just reduces it by a few orders of magnitude. SSR's typically leak something on the order of 1mA when off, when working with line voltages.

A good model for understanding SSR behavior is a pair of resistors, one a high value resistor that is always connected between the power terminals, and the other a low value resistor that is switched to be either disconnected, or connected in parallel with the high value resistor. This is shown in the schematic below:

To analyze this circuit we need to use Ohm's law, which can be written three different ways, depending on what value you want to calculate:

V = I * R

R = V / I

I = V / R

And we also need the equation for power, which has some alternates if you substitute the first and third forms of Ohm's law into the basic formula:

P = I * V

P = I^2 * R

P = V^2 / R

The value of the larger resistor in the SSR model is picked to get about 1.5 mA leakage @ 240V, so the value is:

R = V / I = 240V / 0.0015A = 160,000 ohms

The voltage drop across the SSR at operating current (22.9 A for 5500 W element) is about 1.25 V, so the value of the smaller resistor needs to be:

R = V / I = 1.25V / 22.9 A = 0.055 ohms

A 5500W element at 240V needs to have a resistance of:

R = V^2 / P = 240V^2 / 5500W = 10.5 ohms

And finally the operating current for 5500 W @ 240 V is:

I = P / V = 5500W / 240V = 22.9 A

The circuit is powered by Hot 1 and Hot 2 both of which are 120 V measured against ground. Since they are 180° out of phase with each other, the voltage measured between points "A" and "C" will be 240 V always (whether the element is plugged in or not, and whether the SSR is off or on.) Point "A" will always be 120 V to ground, as will point "C".

What happens to the voltage at point "B" is what gets interesting.

With the element plugged in, and the SSR off, we have a 10.5 ohm resistor in series with a 160,000 ohm resistor. The total resistance for the loop is then 160,000 + 10.5 = 160,010.5 ohms, and the current flowing is 240V / 160,010.5 = 0.0014999 A, so let's just call it 0.0015 A (1.5 mA - the extra 10.5 ohms of the element has almost no effect on the current flow.) The voltage difference between points "A" and "B" (i.e. voltage on the element) is:

V = I * R = 0.0015A * 10.9 ohms = 0.016 V

So, the voltage at point "A" to ground will be 120 V, and point "B" to ground will be 120 - 0.016 = 119.984, and the power on the "off" element will be 0.0015^2 * 10.5 = 0.0000236 W. Thus the SSR is very effective at removing power from the element, but does not remove voltage from the element. The voltage difference between points "B" and "C" will be 120V + 119.984V = 239.984 V. The power being dissipated by the "off" SSR will be 0.0015^2 * 160,000 = 0.36 W.

With the element plugged in, and the SSR on, the two resisters in the SSR are in parallel, and the formula for the combined resistance from "B" to "C" is:

R[total] = R[1] * R[2] / (R[1] + R[2]) = 0.055 * 160,000 / (0.055 + 160,000) = 0.0549998 ohms

(let's call it 0.055 ohms - here the large resistance in parallel with the small resistance has essentially zero effect.)

So, now we have a 10.5 ohm resistor in series with a 0.055 ohm resistor, for an effective resistance of 10.555 ohms. The current will then be 240V / 10.555 = 22.74 A. The voltage across the element (point "A" to "B") will be 22.74A * 10.5 ohms = 238.75 V. Voltage from "B" to "C" will then be 240V - 238.75V = 1.25 V, and "B" to ground will be 118.75 V. The power to the element will be 238.75V * 22.74A = 5429 W, and the power dissipated in the SSR will be 1.25V * 22.74A = 28 W (which is why they need heat sinks.)

With the element unplugged, and the SSR on or off, there will be 0 current flowing from "A" to "C" (and likewise 0 from "A" to "B" and "B" to "C".) With 0 current, there is 0 voltage drop, so "A" to "B" and "A" to "C" will measure 240 V, and "B" to "C" will measure 0 V. "A", "B", and "C" will all measure 120V to ground.

Brew on

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)