Rondacker

Well-Known Member

Got me thinking about BCS.In a few month's you'll find something to be unhappy about, sell and rebuild.

Got me thinking about BCS.In a few month's you'll find something to be unhappy about, sell and rebuild.

Funny, but true. Right now I am content but definitely have visions of 2.0.

I wish I could brew more to really learn and figure out exactly what changes I would like to make iteratively or for round 2... problem is my friends are all bud/miller/coors light junkies and I can't drink it fast enough. I have 5 beers on tap right now and in a week will be the better part of >15 gallons. Need to hand out growlers!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Not gonna lie... It makes life much easier! I do have a slight problem where water somehow leaks past the lids. Clamping them down helps but I think repositioning the heads lower will help. Baby steps like everything else....

Not yet. I have been thinking about it and I am not exactly sure what is going on. The lid extends down, so it would seem that any water coming in at an angle should be blocked from getting out.

What I *think* is happening is the lid is getting wet and water is holding to the interface between the lid and edge of the kettle via adhesion. Any internal pressure rise (heating water, etc.) causes that water to push out. Alternatively, or in combination, the PBW causes that water to have less surface tension, allowing some of it to slip passed. I dunno - but it is a major issue because I can't stand there plugging up leaks for two hours while the cycles run!

The gasket idea is good. Just need to figure out the right stuff.

I'm going to be testing heating the strike in the HLT and filling the MLT with dry grain and then transferring strike water from HLT to MLT underletting the grain.

I started doing this. Fill the MT with dry grain then slowly pump strike water into the bottom of the MT. No need to use a mash paddle anymore. I haven't seen any effect on my efficiency so Im pretty sure I'm not getting any dough balls.

Good to know! Do you not stir your mash at all? Do you run a continuous recirulation?

(Sorry BrunDog for the OT!)

Correct, no stirring the mash at all. Haven't touched my mash paddle for the last 7 or 8 brews. I have a herms setup so I am continously recirulating the entire mash.

What temp is the strike water when you pump it in? Same as a single infusion?

I guess that would be a consideration. With recirculation before doughing-in (done that way on my rig, anyway), or pumping over heated strike water (most HLT systems), everything reaches a nearly equal temp (kettle, tubing, recirc hardware, etc.). Via underletting, the local grain is exposed to much hotter water, then as the water spreads to the edges, heat is pulled out into the kettle. This would create temp differences for some period of time, depending on how quickly the water is introduced (~5 minutes?).

In theory/worse case scenario, the local grain gets overheated and the edge grain starts converting at a lower temp than desired. I don't know if this would amount to a hill of beans, just something to consider.

I typically try to dough in as quickly as possible to get uniform temps fast. I get the grain in quick, give a couple of stirs, then get the re-circulation going ASAP. I am not big into stirring the mash for 5 mins like some guys do on their YouTube vids. Probably too anal, but hey that's me!

BTW I will send you my sketch. Just need to pull it out of the programming laptop, which I don't fire up unless I am editing it.

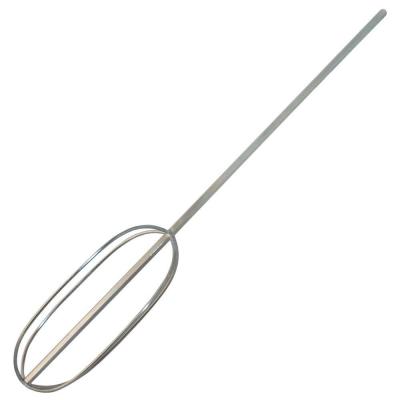

I didn't see a mixer Jon. Is that something that is in the works or you just didn't photo it?