Assuming isolation means no flow... then yes, at least for the valves I use. It is a ball valve with a special V cut in it to "linearize" the flow. There is about zero flow below ~20% open. They work great IMO... I have one on the output of each of my two pumps.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BrunDog 50A eRig - no HLT for me!

- Thread starter BrunDog

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Assuming isolation means no flow... then yes, at least for the valves I use. It is a ball valve with a special V cut in it to "linearize" the flow. There is about zero flow below ~20% open. They work great IMO... I have one on the output of each of my two pumps.

I didn't know V ball valves were within the grasp of us lowly home brewers. I've used them plenty of times in industrial applications, but always assumed they would be too expensive for an individual to use it at home.

- Joined

- Mar 24, 2016

- Messages

- 558

- Reaction score

- 60

Brundog,

Do you treat your sparge water?

Thx

Do you treat your sparge water?

Thx

I have but generally don’t. Because I use stored RO water which both fills and sparges, it would take a bit of work: either acidify all the water then back it out with salts in the mash or acidify the stored water during the mash.

I have been putting all my salts in the mash with great success. Bru’NWater (sp?) has calculations for this and has been spot-on. Basically I let my strike water fill and heat, then add the salts right before or simultaneous to dough-in.

Since RO has no alkalinity, my understanding is acidifying it for sparge is not necessary. So I don’t. Getting good efficiency etc. so have been keeping this method.

I have been putting all my salts in the mash with great success. Bru’NWater (sp?) has calculations for this and has been spot-on. Basically I let my strike water fill and heat, then add the salts right before or simultaneous to dough-in.

Since RO has no alkalinity, my understanding is acidifying it for sparge is not necessary. So I don’t. Getting good efficiency etc. so have been keeping this method.

Upgrades coming...

- Joined

- Mar 24, 2016

- Messages

- 558

- Reaction score

- 60

Upgrades coming...View attachment 568228

Are you creating the 0-5v signal similiarly to your proportional valves?

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$33.98

DYKWSWYX Heavy Duty Brewing Gloves (1 Pair) - 55CM Long Chemical Resistant Plastic Gloves for Beer & Wine Making, Cleaning, Homebrew Equipment Protection

wuhanshijiayangzhiyimaoyiyouxiangongsi

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

Yessir!

BTW, there is a choice to create analog signals... First, for high impedance devices (like this one), you can use a basic R-C filter to create a low pass filter and feed the output to the control signal input of the device. R-C filter is just a resistor and capacitor in series from the interface output to ground, with the "output" the point they are connected.

Alternatively, BruControl now makes Analog Amplifier boards to convert an interface's PWM into an analog signal. The can convert 3.3V or 5V PWM into 0-5V, 0-10V, 0-12V, etc. for whatever control system needs it. These work well with higher impedance devices like the proportional valves. I have successfully run my proportionals using the above R-C filter, but technically the analog amplifier is a better route.

BTW, there is a choice to create analog signals... First, for high impedance devices (like this one), you can use a basic R-C filter to create a low pass filter and feed the output to the control signal input of the device. R-C filter is just a resistor and capacitor in series from the interface output to ground, with the "output" the point they are connected.

Alternatively, BruControl now makes Analog Amplifier boards to convert an interface's PWM into an analog signal. The can convert 3.3V or 5V PWM into 0-5V, 0-10V, 0-12V, etc. for whatever control system needs it. These work well with higher impedance devices like the proportional valves. I have successfully run my proportionals using the above R-C filter, but technically the analog amplifier is a better route.

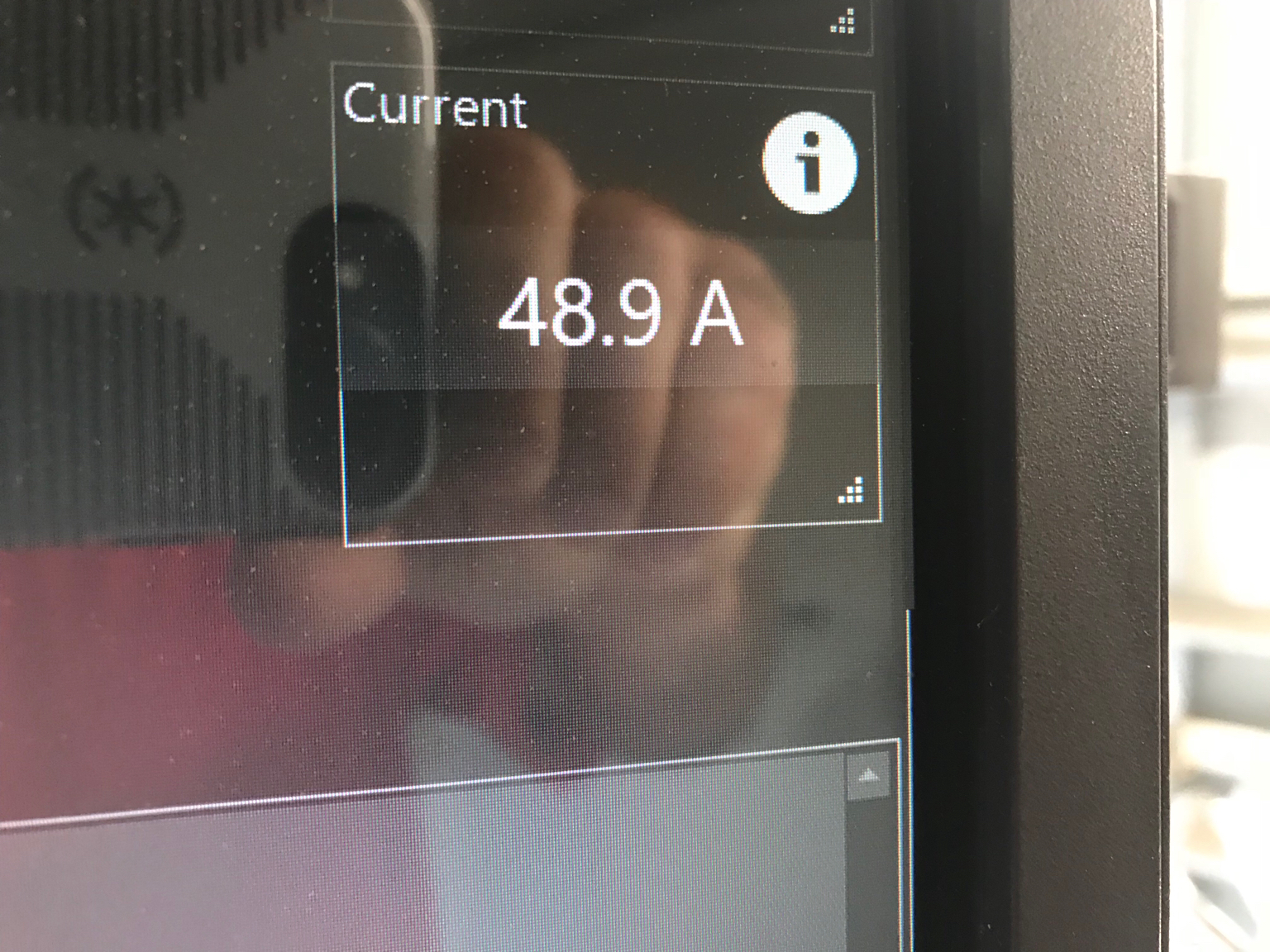

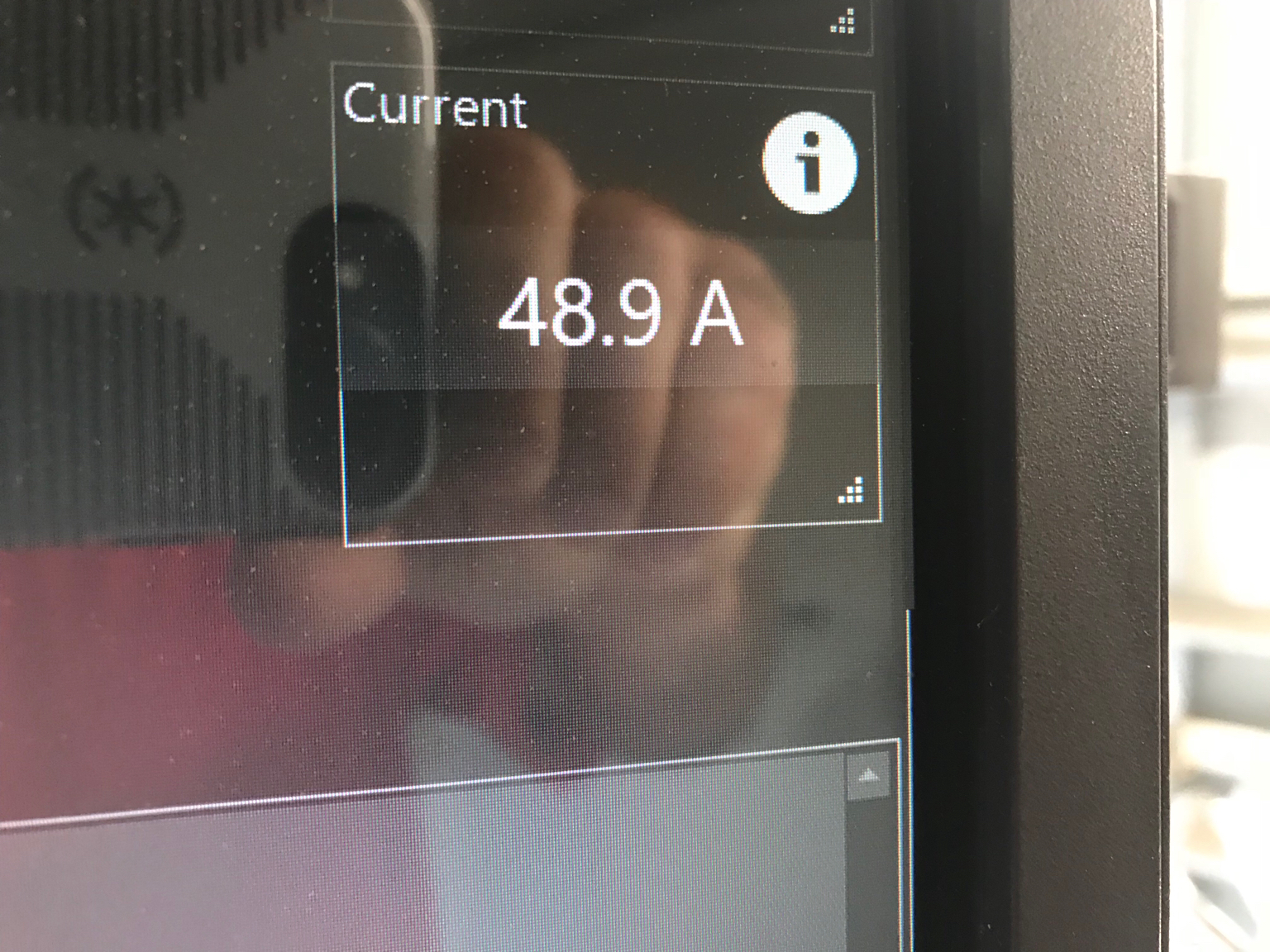

Something so satisfying about using the whole fifty! I feel like a hundred would be better somehow though...

augiedoggy

Well-Known Member

lol I have two of them in my big panel and had them both up to about 45/ 48 .. Still wish they made a 60 amp version since I have 120amps total coming in but wired my panel not to exceed 100.Something so satisfying about using the whole fifty! I feel like a hundred would be better somehow though...

View attachment 581338

What amp meter are you using to to bring this into Brucontrol? I'm assuming you're not using the typical ones with the panel mount display.Something so satisfying about using the whole fifty! I feel like a hundred would be better somehow though...

View attachment 581338

Does your cleaning cycle clean up all hoses and threaded fittings or is it necessary to clean them manually sometimes?

Well, I run PBW through everything that water, grain, or wort touches... So *theoretically* it is getting into all the same nooks and crannies... but in truth I have never taken the parts apart to see how clean it all gets. I would imagine its very possible there are certain areas where either PBW can't reach or is ineffective.

What amp meter are you using to to bring this into Brucontrol? I'm assuming you're not using the typical ones with the panel mount display.

It's in this thread or the BC one but I did a quick search and couldn't locate it. I'll try again in a couple of hours if isn't found before then.

@TexasWine--I believe it's this one. I actually have an extra one (ordered too many things at once and then didn't open the box) that I'd be willing to send you for a couplea bucks. You can PM if you're interested.What amp meter are you using to to bring this into Brucontrol? I'm assuming you're not using the typical ones with the panel mount display.

Last edited by a moderator:

Thats the one!

BrunDog, quick question about these (and other) current meters: they will not give you the total current including all 120v devices, right? I.e. my understanding is that the meter will give you 240v current plus the 120v current of anything that runs off the leg that goes through the little donut on the meter (in my case Hot2/black), but not 120v devices that run off the other hot leg. Is my understanding correct? Thanks!

BrunDog, quick question about these (and other) current meters: they will not give you the total current including all 120v devices, right? I.e. my understanding is that the meter will give you 240v current plus the 120v current of anything that runs off the leg that goes through the little donut on the meter (in my case Hot2/black), but not 120v devices that run off the other hot leg. Is my understanding correct? Thanks!

Yessir, correct. This is no different then panel mount contained units. If you wanted to measure the other leg, you could add a sensor there, but then know the 240V devices will be represented in BOTH sensors, then the 120V legs will be above those numbers. In my personal system, I know mentally there are a couple of additional amps going to the other leg.

Another solution would be to go all 240V devices (pumps, power supplies, etc.). Then you can measure all the current on one leg.

VinceBrews

Well-Known Member

- Joined

- Oct 26, 2013

- Messages

- 59

- Reaction score

- 6

Brundog, et al.

I have a Kal clone I built a couple years ago and I'm about ready to upgrade it and automate a lot of it. I've found your build very inspiring and I will be implementing a lot of what you've done, including BC. My specific question for today is about your automated CIP solution. In particular, there was a bit of discussion about the lids of your kettles leaking with the use of a CIP ball. I have 20g Bayou Classic kettles and I'm concerned about being able to seal the lids. There was discussion about using saran wrap, which is not a solution I'm particularly excited about. Have you solved this issue and how?

My apologies if this was answered already and I missed it.

Thanks,

Vince

I have a Kal clone I built a couple years ago and I'm about ready to upgrade it and automate a lot of it. I've found your build very inspiring and I will be implementing a lot of what you've done, including BC. My specific question for today is about your automated CIP solution. In particular, there was a bit of discussion about the lids of your kettles leaking with the use of a CIP ball. I have 20g Bayou Classic kettles and I'm concerned about being able to seal the lids. There was discussion about using saran wrap, which is not a solution I'm particularly excited about. Have you solved this issue and how?

My apologies if this was answered already and I missed it.

Thanks,

Vince

What are the white pvc canisters on the right?Hi HBT Brothers and Sisters,

I have learned so much incredible information via this forum, I thought it a good time to post up my rig and learnings as it may possibly help others. This is a 2 Vessel 50A electric rig that is mostly built, though upgrades will always be ongoing. It is similar to most other rigs, but here are some of the highlights:

- - 2 vessel, 50A, 2x5500W elements

- - BCS 462 powered

- - Direct sparge and strike water heating via RIMS tube

- - Dual voltage RIMS power

- - Dual flowmeters for autosparge and safety, powered via Arduino

- - Dual control box (main and console)

- - Inline O2 and poor man's sight glass

- - Cart design with onboard RO water storage

I will break these down into more detail in threads below. Please feel free to reply with any questions or comments. This is, like anything else, a work in progress. My next steps will be to possibly add electric ball valves, sight glass sensors, and anything else that gives me the tickles.

View attachment 301448

-BD

These are my chillers - homegrown tube-in-shell design. I posted it somewhere in the forum here - I can find if interested.

I was wondering if they were a home made RO system.These are my chillers - homegrown tube-in-shell design. I posted it somewhere in the forum here - I can find if interested.

I remember there being a video of your brew day on this rig. Do you have the link handy by chance?Assuming isolation means no flow... then yes, at least for the valves I use. It is a ball valve with a special V cut in it to "linearize" the flow. There is about zero flow below ~20% open. They work great IMO... I have one on the output of each of my two pumps.

Similar threads

- Replies

- 2

- Views

- 3K

- Replies

- 0

- Views

- 2K