Trying to understand the benefits to BC Pro over Advanced. What third party applications may come in handy?

Hi,

I develop a website called

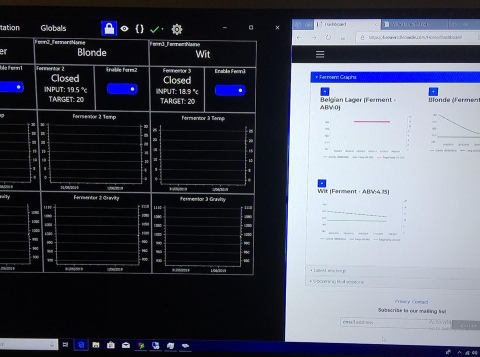

Brewers Chronicle which allows brewers to record all their boil and fermentation details. I am just finishing up a plug-in (and documentation) for CraftBeerPi 3 this month, but one of my clients is already using BruControl to control their local fermentation devices and I have written a Windows service which sync's data between BruControl and Brewers Chronicle.

This service requires the professional version of BruControl to access the API for data exchange.

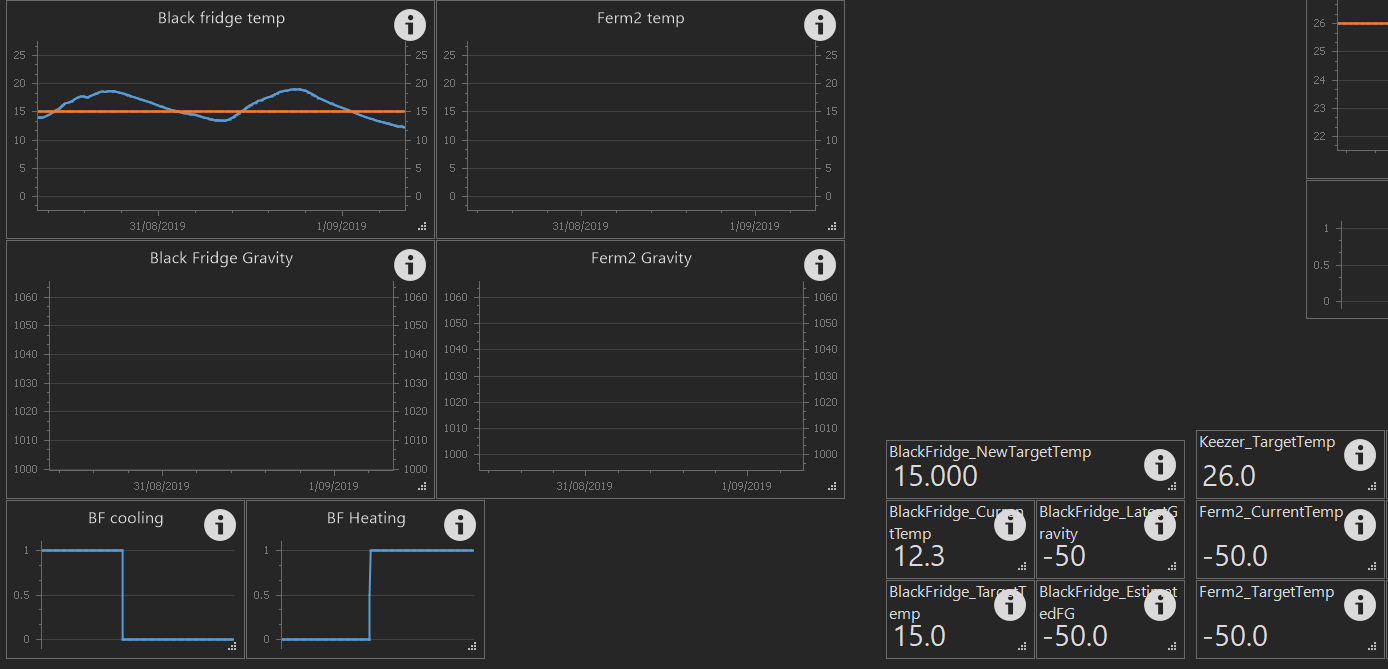

Brewers Chronicle provides a dashboard of current ferments with graphs for temperature and gravity readings accessible from anywhere on any device. You can also produce a ferment report which includes temperature, gravity and pH graphs, all your boil session details, and all ferment temperature gravity readings.

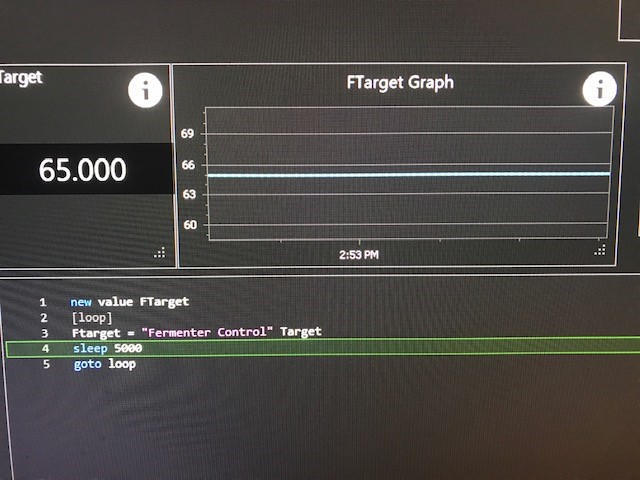

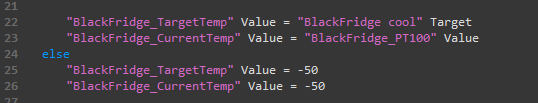

If you are using a Tilt or iSpindel device, then you can create a gravity-based ferment temperature schedule. Part of the sync'ing process passes down the latest calculated target temperature based on received gravity readings and applies it to the relevant device in BruControl. So you then have fully automated gravity-reading controlled ferments.

There is also a feature for receiving SMS's when your ferment temps go out of range from your target temperature. No more brews being cooked over the weekend when you are not there. Not sure how this will work for international numbers as I am based in Australia.

This client install includes LCD's fitted to the Arduino enclosure so you can geek out on values right next to your fermentor.

So I see a really good fit between BruControl and my website. BruControl fully controls all local operations, but passes out all the historical and reporting data to Brewers Chronicle.

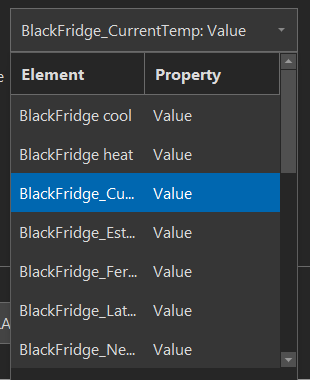

At this stage I don't have any documentation on the setup, but it a few global variables per fermentor and some fairly basic scripting. My windows service does the bulk of the work.

I am planning on producing documentation next month for the integration. I'll be looking for a couple of people to trial it out, so will post here when I'm ready.

Thanks,

Angus.

PS: Hope you don't mind the massive advertisement,

@BrunDog

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)