You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brewzilla Gen4 Discussion/Tips Talk

- Thread starter stealthfixr

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

hungupdown

Well-Known Member

After initially suffering a few badly 'stuck' mashes in BZ g4, I now always leave for 15 - 20min before starting recirculation (and then recirculate slowly for 10min).There are some claims that letting the bed naturally settle helps avoid compaction. I've been trying it out and haven't seen significant effects, but can't rule it out entirely. It may depend on pump strength or something.

When searching for solutions, I found the G.Wheeler advice on avoiding a compacted grain bed. Which is to gradually add grain (after premixing dry), stirring just enough to break up dough balls, without knocking off any trapped air. This air increases grain buoyancy, and gives a more open grain bed.

Then allow a grain bed rest (of 15-20min) for the grain (and flour) to hydrate and swell. After the swollen grain interlocks, it shouldn't then collapse when recirculation starts.

Early recircilulation can wash through the flour, to settle on (heater) base, and can squeeze the grain tightly together.

Grain bed compaction, is more likely to be an issue in malt pipes with a tall narrow profile, such as the BZ G4 (rather than with wide shallow profiles).

I often mash with sticky grains, eg 60% malted wheat. But since changing method, never get stuck mashes.

Whirlpools works by forming a centre cone of trub.BZ Gen 4 is bottom drain. They sell an add-on... Bottom HED plate (heat exchanger disk?)... Works great. Yes... To whirlpool.

The basic BZ g4 has a center drain hole. So trub cone forms over drain.

The HED is a solid central plate (with gap to allow flow around the perimeter). So trub cone shouldn't affect flow.

So agree, HED great / only way to whirlpool in g4.

Barão

Well-Known Member

- Joined

- Jun 18, 2020

- Messages

- 191

- Reaction score

- 50

When searching for solutions, I found the G.Wheeler advice on avoiding a compacted grain bed. Which is to gradually add grain (after premixing dry) .....After initially suffering a few badly 'stuck' mashes in BZ g4, I now always leave for 15 - 20min before starting recirculation (and then recirculate slowly for 10min).

When searching for solutions, I found the G.Wheeler advice on avoiding a compacted grain bed. Which is to gradually add grain (after premixing dry), stirring just enough to break up dough balls, without knocking off any trapped air. This air increases grain buoyancy, and gives a more open grain bed.

Then allow a grain bed rest (of 15-20min) for the grain (and flour) to hydrate and swell. After the swollen grain interlocks, it shouldn't then collapse when recirculation starts.

Early recircilulation can wash through the flour, to settle on (heater) base, and can squeeze the grain tightly together.

Grain bed compaction, is more likely to be an issue in malt pipes with a tall narrow profile, such as the BZ G4 (rather than with wide shallow profiles).

I often mash with sticky grains, eg 60% malted wheat. But since changing method, never get stuck mashes.

Whirlpools works by forming a centre cone of trub.

The basic BZ g4 has a center drain hole. So trub cone forms over drain.

The HED is a solid central plate (with gap to allow flow around the perimeter). So trub cone shouldn't affect flow.

So agree, HED great / only way to whirlpool in g4.

You mix the dry grains in the basket first...and then put the basket in the water ?

Scarabrew

Well-Known Member

Has anyone tried to replace the "garden like" tap?

It doesn't have to be as fancy as a tri clamp version (like Brad used), but at least an intermediate threaded version.

It doesn't have to be as fancy as a tri clamp version (like Brad used), but at least an intermediate threaded version.

hungupdown

Well-Known Member

When searching for solutions, I found the G.Wheeler advice on avoiding a compacted grain bed. Which is to gradually add grain (after premixing dry) .....

You mix the dry grains in the basket first...and then put the basket in the water ?

Basket? I'm in Scotland, with many different device names.

I mx in a spare brewbucket. Then gradually add to water in (immersed) malt pipe.

I haven't messed with it, but the drain and pump are barb connections with 1/2" silicone*. I imagine you could swap to anything with a similarly sized barb.Has anyone tried to replace the "garden like" tap?

It doesn't have to be as fancy as a tri clamp version (like Brad used), but at least an intermediate threaded version.

View attachment 875202

*Kegland used molded silicone elbows and offsets. Take note if rearranging.

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$33.98

DYKWSWYX Heavy Duty Brewing Gloves (1 Pair) - 55CM Long Chemical Resistant Plastic Gloves for Beer & Wine Making, Cleaning, Homebrew Equipment Protection

wuhanshijiayangzhiyimaoyiyouxiangongsi

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

BandonBrewingCo

Well-Known Member

I only use it for draining during cleaning so not too pushed tbh, even if it does feel wobblyHas anyone tried to replace the "garden like" tap?

It doesn't have to be as fancy as a tri clamp version (like Brad used), but at least an intermediate threaded version.

View attachment 875202

Yeah, I actually removed the T and the bottom valve is not even connected.I only use it for draining during cleaning so not too pushed tbh, even if it does feel wobbly

DuncB

Well-Known Member

On my AIO I took the tap out and fitted a whirlpool with a ball lock.

BandonBrewingCo

Well-Known Member

No issues draining it?Yeah, I actually removed the T and the bottom valve is not even connected.

Nope. I recirc over the IC, then pump into the fermenter at same height as the Brewzilla. Works great.No issues draining it?

(I do store it upside down in case there's any residual moisture.)

BandonBrewingCo

Well-Known Member

Was thinking that alright. Good to know there's a plan b if the wobbly tap gets on my nerves too much.Nope. I recirc over the IC, then pump into the fermenter at same height as the Brewzilla. Works great.

(I do store it upside down in case there's any residual moisture.)

It has been very rare for me to have issues with grain. I know people who have done that BIAB within the malt pipe, it works. Your issues mostly would be remedied by milling less fine and waiting 10-15 minutes before turning the pump on. I have the same unit.Brewzilla gen .4 with BIABI

I have a problem with the tap and pump clogging due to the central hole. What do you think about using a BIAB bag inside the grain basket?

I do a single pass mill to credit card thickness and have 75-80% efficiency. Most of my initial issues seemed to stem from double pass milling and turning the pump on too early after doughing in. I also have the HED which seems to help collect a lot of trub.

Corey Foust

New Member

- Joined

- Apr 8, 2023

- Messages

- 2

- Reaction score

- 0

I had the same issue espically when doing 20+ pounds of grains. I use a large nylon bag between the tub and the grain tower which has helped alot. The nylon bag usually last 5-7 brews and then starts to melt due the heat in the tub (using a 65L 220w Gen 4).Brewzilla gen .4 with BIABI

I have a problem with the tap and pump clogging due to the central hole. What do you think about using a BIAB bag inside the grain basket?

I might consider puting the bag in the grain tower next brew to prevent it from getting hot. I never use the bag once I start to boil.

Love the gen 4, have brewed over 60 batches in the last 3 years. Its not perfect but it gets the job done. I recently had to upgrade my pump to what they now use in the gen 4.1 65L. My largest batch had 39 pounds of grain.

Barão

Well-Known Member

- Joined

- Jun 18, 2020

- Messages

- 191

- Reaction score

- 50

Thanks for the reply...I just didn't understand...do you use the grain bag on the outside or inside of the basket?I had the same issue espically when doing 20+ pounds of grains. I use a large nylon bag between the tub and the grain tower which has helped alot. The nylon bag usually last 5-7 brews and then starts to melt due the heat in the tub (using a 65L 220w Gen 4).

I might consider puting the bag in the grain tower next brew to prevent it from getting hot. I never use the bag once I start to boil.

Love the gen 4, have brewed over 60 batches in the last 3 years. Its not perfect but it gets the job done. I recently had to upgrade my pump to what they now use in the gen 4.1 65L. My largest batch had 39 pounds of grain.

Barão

Well-Known Member

- Joined

- Jun 18, 2020

- Messages

- 191

- Reaction score

- 50

Thanks for the feedback...I buy the malts already ground...I wait 15 minutes before turning on the pump...100% pump power...I adjust it using the ball valve...I use 4 liters of water/kg of grain...total water...without sparging...I transfer it to the fermenter using the TAP...I don't use the pump ...Even so I have problemsIt has been very rare for me to have issues with grain. I know people who have done that BIAB within the malt pipe, it works. Your issues mostly would be remedied by milling less fine and waiting 10-15 minutes before turning the pump on. I have the same unit.

I do a single pass mill to credit card thickness and have 75-80% efficiency. Most of my initial issues seemed to stem from double pass milling and turning the pump on too early after doughing in. I also have the HED which seems to help collect a lot of trub.

I use a Brew Bag inside the grain basket, works great for me. I mill as fine as my mill will go and typically get around 70% efficiency. I've never had the pump clog.Brewzilla gen .4 with BIABI

I have a problem with the tap and pump clogging due to the central hole. What do you think about using a BIAB bag inside the grain basket?

I use a wilser bag with no malt pipe.

The HED disc helps a lot catching hops and also keeping the center hole/pump unclogged.

I found it easier without the malt pipe. Also one less thing to clean

The HED disc helps a lot catching hops and also keeping the center hole/pump unclogged.

I found it easier without the malt pipe. Also one less thing to clean

I’m using a Brewzilla 3.1.1.I just received my Brewzilla Gen 4 last week (110 Volt system).

1. There are two ways to sparge. The first way is to mash, mash out, then lift the pipe to drain completely. Then start adding sparge water to the grain, using say a 2-liter measuring container, pouring gently over the grains. The second way is to mash, mash out, lift the pipe to drain completely, then remove what has been collected and leave it temporarily in a separate pot. Then drop the pipe with the grain, add your sparge water, stir, let it settle, then lift the pipe up to drain again. Repeat this if you want to add more sparge water. Once you are finished sparging, add the wort that was kept aside and you can begin your boil. You will likely get better efficiency using this latter method, but it wil take a little longer.

2. As far as I know, there is no need to do a whirlpool, especially since there are already two filters in place. I intend to use the bottom faucet to drain off a pint or so after chilling and before transferring the wort to the fermenter. That pint is used to remove any trub that might have accumulated in the "dome". The rest should be fairly clear.

I’m dumping my Sparge water into the lifted pipe as soon as I have it up.

I have 32l in the kettle overnight, with a timer to get it to strike temp for when I plan to start. I then take off my 8l Sparge water into a metal pot, leaving 24l to mash.

Pot goes onto the stove and I add some heat to get back to 65c during mash out. I’m trying to avoid tannin so don’t want Sparge too hot.

I’m recirculating through my entire mash time so I hope most sugars have been extracted by the time mashing is over.

Sparge is just to flush off remaining fermentables, but if I haven’t got them out yet, maybe I need to mash longer..?

I don’t understand why I need to take ages to sparge if I’ve been recirculating through a wet mash…?

Bottoms_Up

Well-Known Member

I consistently use a grain bag outisde of the grain basket (pipe). The pipe fits in it exactly. I feel that having the bag outside, instead of inside the pipe, allows the water to circulate more freely. With this set-up, I have no trub when I bring it to the fermenter. I also have no clogging issues.Brewzilla gen .4 with BIABI

I have a problem with the tap and pump clogging due to the central hole. What do you think about using a BIAB bag inside the grain basket?

Last edited:

Bottoms_Up

Well-Known Member

Sparging gently allows the sparge water to penetrate as much grain as possible, in order to absorb the rest of the sugars in the grain bed. If you sparge too quickly, it may form channels in the grain to let the sparge water through, thereby missing much of the grain.I’m using a Brewzilla 3.1.1.

I’m dumping my Sparge water into the lifted pipe as soon as I have it up.

I have 32l in the kettle overnight, with a timer to get it to strike temp for when I plan to start. I then take off my 8l Sparge water into a metal pot, leaving 24l to mash.

Pot goes onto the stove and I add some heat to get back to 65c during mash out. I’m trying to avoid tannin so don’t want Sparge too hot.

I’m recirculating through my entire mash time so I hope most sugars have been extracted by the time mashing is over.

Sparge is just to flush off remaining fermentables, but if I haven’t got them out yet, maybe I need to mash longer..?

I don’t understand why I need to take ages to sparge if I’ve been recirculating through a wet mash…?

Barão

Well-Known Member

- Joined

- Jun 18, 2020

- Messages

- 191

- Reaction score

- 50

Thanks for the answer... There is no problem of RIPPING the bag of grains outside the grain basket when lifting the basket and supporting it ?I consistently use a grain bag outisde of the grain basket (pipe). The pipe fits in it exactly. I feel that having the bag outside, instead of inside the pipe, allows the water to circulate more freely. With this set-up, I have no trub when I bring it to the fermenter. I also have no clogging issues.

Depending on the quality of the bag there is absolutely no reason to worry.Thanks for the answer... There is no problem of RIPPING the bag of grains outside the grain basket when lifting the basket and supporting it ?

Photo is from the internet of two different bags hoisted using two different methods. Granted it's not in an AIO system, but I did it this way before getting a false bottom in my old 3 vessel system.

Barão

Well-Known Member

- Joined

- Jun 18, 2020

- Messages

- 191

- Reaction score

- 50

THANKSDepending on the quality of the bag there is absolutely no reason to worry.

Photo is from the internet of two different bags hoisted using two different methods. Granted it's not in an AIO system, but I did it this way before getting a false bottom in my old 3 vessel system.

View attachment 877907

Thank you.Sparging gently allows the sparge water to penetrate as much grain as possible, in order to absorb the rest of the sugars in the grain bed. If you sparge too quickly, it may form channels in the grain to let the sparge water through, thereby missing much of the grain.

Mine doesn’t get a chance to form channels because I’m filling up before the liquid level gets below the top of the grain. It’s just an extension of the draining down from the malt pipe but a few degrees cooler.

My point is, what is the true value of sparging, if the wort has been recirculating for the whole mash?

I can understand the benefit if the mash is static, with a few stirs along the way.

Has anyone done any experiments to check this?

I’m using a Brewzilla 3.1.1.

I’m dumping my Sparge water into the lifted pipe as soon as I have it up.

I have 32l in the kettle overnight, with a timer to get it to strike temp for when I plan to start. I then take off my 8l Sparge water into a metal pot, leaving 24l to mash.

Pot goes onto the stove and I add some heat to get back to 65c during mash out. I’m trying to avoid tannin so don’t want Sparge too hot.

I’m recirculating through my entire mash time so I hope most sugars have been extracted by the time mashing is over.

Sparge is just to flush off remaining fermentables, but if I haven’t got them out yet, maybe I need to mash longer..?

I don’t understand why I need to take ages to sparge if I’ve been recirculating through a wet mash…?

Think of it like a washing machine. You add soap, and the agitation and soap and water clean the clothes. The machine drains, and spins, and much of the soaping water is removed. However, the rinse cycle will fill, agitate, and then drain and spin again. That ‘rinse’ gets off anything still on the clothes.

Sparging is similar. Through diffusion, the sugars still ‘stuck’ to the grain will move into the lower sugared water and then be able to be drained. Rinsing the grain with wort doesn’t work the same way- because diffusion requires a lower concentration in order for the higher concentration (the sugars) to move to the rinse water.

Think of it like a washing machine. You add soap, and the agitation and soap and water clean the clothes. The machine drains, and spins, and much of the soaping water is removed. However, the rinse cycle will fill, agitate, and then drain and spin again. That ‘rinse’ gets off anything still on the clothes.

Sparging is similar. Through diffusion, the sugars still ‘stuck’ to the grain will move into the lower sugared water and then be able to be drained. Rinsing the grain with wort doesn’t work the same way- because diffusion requires a lower concentration in order for the higher concentration (the sugars) to move to the rinse water.

That said, I myself no longer sparge. I do a full volume mash, and move on. The loss of a few gravity points doesn’t mean much to me, and my last batch two days ago with a full volume mash has an efficiency of 72% so that’s good enough for me.

The thing for me is, a full volume mash doesn’t fit in my Brewzilla so I started using the Brewzilla as an HLT and a boil kettle and dug out my old cooler MLT to mash in. Lots of reasons beside the volume- at my age and size and brewing indoors, I just can’t deal with that heavy malt pipe even with a bag in it. So I pump the heated water to my cooler, and BIAB full volume there, and gravity drain to the Brewzilla, and start the boil. In the mean time, I can squish the grain in the bag with my mash paddle, and drain any wort from the grain into the Brewzilla. It’s a piece of cake then to just take the entire cooler outside to dump the grain bag in my compost. (Unless I save some to make dog cookies).

It’s two vessels instead of one, defeating the purpose of the AIO I guess, but it’s the easiest way for me to deal with 15 pounds of wet grain and still have easy clean up and no mess/drips.

Barão

Well-Known Member

- Joined

- Jun 18, 2020

- Messages

- 191

- Reaction score

- 50

I'm referring to lifting the grain basket with the bag outside in the Brewzila gen 4... there are supports on the sides... it could tear the bagDepending on the quality of the bag there is absolutely no reason to worry.

Photo is from the internet of two different bags hoisted using two different methods. Granted it's not in an AIO system, but I did it this way before getting a false bottom in my old 3 vessel system.

View attachment 877907

Bottoms_Up

Well-Known Member

The Brew Bag is very sturdy with handles, But I raise the basket and the bag at the same time. I lift the basket itself with the bar, but use my other hand to hold the bag in place with one of the the handles of the bag. The bag is very light since almost all of the grain is inside the basket. There's only a little grain trub in the bag.Thanks for the answer... There is no problem of RIPPING the bag of grains outside the grain basket when lifting the basket and supporting it ?

This is the bag I use:

https://www.brewinabag.com/?srsltid=AfmBOooNlFaEBxjfJ3SE7ZvMW32g1hL4xcthpIRG-cEKXX8YqPiyNEpR

(Search for "Brewzilla G4 35 L Basket")

Last edited:

Barão

Well-Known Member

- Joined

- Jun 18, 2020

- Messages

- 191

- Reaction score

- 50

'm referring to lifting the grain basket with the bag outside in the Brewzila gen 4... there are supports on the sides... it could tear the bagThe Brew Bag is very sturdy with handles, But I raise the basket and the bag at the same time. I lift the basket itself with the bar, but use my other hand to hold the bag in place with one of the the handles of the bag. The bag is very light since almost all of the grain is inside the basket. There's only a little grain trub in the bag.

This is the bag I use:

https://www.brewinabag.com/?srsltid=AfmBOooNlFaEBxjfJ3SE7ZvMW32g1hL4xcthpIRG-cEKXX8YqPiyNEpR

(Search for "Brewzilla G4 35 L Basket")

If you are going to go that far why wouldn't you just remove the basket and just do a bag? Seems like you'd just be adding extra stuff to clean with limited reward.'m referring to lifting the grain basket with the bag outside in the Brewzila gen 4... there are supports on the sides... it could tear the bag

If you want to do BIAB, I'd probably do it in the kettle with no basket. Or do it within the basket.

Those feet in the outside of the basket might tear the bag, cut them off if you want the bag on the outside?

Thank you. That is a helpful way to think of it.Think of it like a washing machine. You add soap, and the agitation and soap and water clean the clothes. The machine drains, and spins, and much of the soaping water is removed. However, the rinse cycle will fill, agitate, and then drain and spin again. That ‘rinse’ gets off anything still on the clothes.

Sparging is similar. Through diffusion, the sugars still ‘stuck’ to the grain will move into the lower sugared water and then be able to be drained. Rinsing the grain with wort doesn’t work the same way- because diffusion requires a lower concentration in order for the higher concentration (the sugars) to move to the rinse water.

So if the “clothes” are packed in tightly, the “rinse” has to be more careful because there is still quite a bit of “soap” left after the water drains the first time. If the “clothes” are loose, more soap would be in solution and less in the clothes when it first drains out. The “rinse” has less to do if most of the “soap” went out with the first draining.

Aren’t we into parti-gyle territory now?

In essence, we are sparging to strip off anything that is hanging around, without refilling the water and mashing again.

Might be fun to try that one day, maybe with a small batch, then refill, mash, and see how much sugar is left in the second runnings, before adding that to the fist lot

Thank you. That is a helpful way to think of it.

So if the “clothes” are packed in tightly, the “rinse” has to be more careful because there is still quite a bit of “soap” left after the water drains the first time. If the “clothes” are loose, more soap would be in solution and less in the clothes when it first drains out. The “rinse” has less to do if most of the “soap” went out with the first draining.

Aren’t we into parti-gyle territory now?

In essence, we are sparging to strip off anything that is hanging around, without refilling the water and mashing again.

Might be fun to try that one day, maybe with a small batch, then refill, mash, and see how much sugar is left in the second runnings, before adding that to the fist lot

No. The point isn't how tight they are packed, although of course you want the grain loose in the bag or malt pipe. It's the process of diffusion that we're looking at. Diffusion is why you use water instead of wort to rinse the grains.

If you are batch sparging, you add the water all at once to the drained mash and stir thoroughly and drain, If fly (continous) sparging, you slowly add the sparge water to the mash at the same rate it is drained. Both work.

Thank youNo. The point isn't out tight they are packed, although of course you want the grain loose in the bag or malt pipe. It's the process of diffusion that we're looking at. Diffusion is why you use water instead of wort to rinse the grains.

If you are batch sparging, you add the water all at once to the drained mash and stir thoroughly and drain, If fly (continous) sparging, you slowly add the sparge water to the mash at the same rate it is drained. Both work.

Bottoms_Up

Well-Known Member

Yes, that was what I was describing. I've rested the basket and bag on those rests numerous times, with no sign of wear on the bag. The mesh is quite tough - not cloth, and almost impossible to tear. Since it's not cloth, it also dries quite rapidly.'m referring to lifting the grain basket with the bag outside in the Brewzila gen 4... there are supports on the sides... it could tear the bag

Barão

Well-Known Member

- Joined

- Jun 18, 2020

- Messages

- 191

- Reaction score

- 50

thanksYes, that was what I was describing. I've rested the basket and bag on those rests numerous times, with no sign of wear on the bag. The mesh is quite tough - not cloth, and almost impossible to tear. Since it's not cloth, it also dries quite rapidly.

I've done some experiments. I'll dig them up and share. One was Anvil AIO where I mashed: full volume no recirc, full volume with recirc, mash then batch sparge. Sparge made a notable efficiency difference.Thank you.

Mine doesn’t get a chance to form channels because I’m filling up before the liquid level gets below the top of the grain. It’s just an extension of the draining down from the malt pipe but a few degrees cooler.

My point is, what is the true value of sparging, if the wort has been recirculating for the whole mash?

I can understand the benefit if the mash is static, with a few stirs along the way.

Has anyone done any experiments to check this?

I also did an experiment in a 3-vessel setup comparing batch sparge and fly sparge while also recording times.

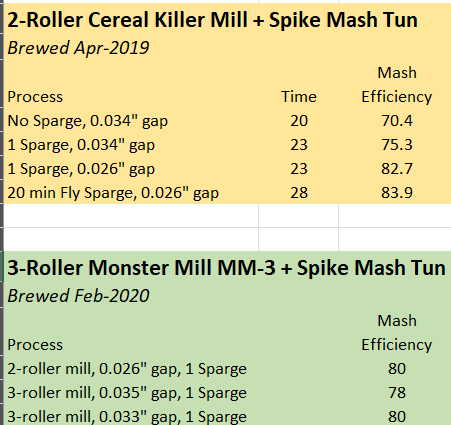

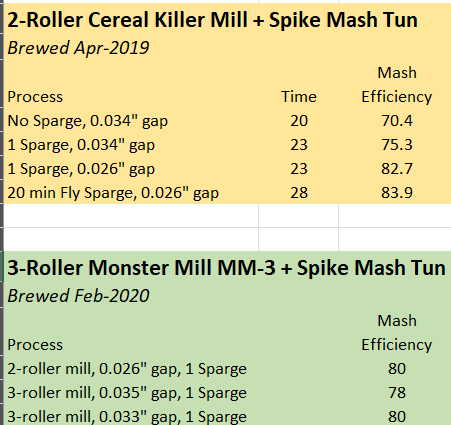

First I did some experiments while evaluating a 3-roller grain mill. I iterated through a couple different sparge processes using a 2-3 vessel system, utilizing a recirculating mash RIMS system. I did this with multiple batches of grain from the same sack to try to minimize grain variation contribution. Then I just did the mash, collected the data, and made the following tables noting the time for the "transfer time from mash end to full boil volume of wort collected".

These were done about a year apart, so the grain batches weren't the same between the 2-roller and 3-roller mill. But all of the 2-roller trials where from the same sack of grain, and all of the 3-roller trials were from its own sack of grain.

These were done about a year apart, so the grain batches weren't the same between the 2-roller and 3-roller mill. But all of the 2-roller trials where from the same sack of grain, and all of the 3-roller trials were from its own sack of grain.

And here's from my review of the Anvil 6.5-gallon unit...

I used a simple mash of 5 lbs of Viking Xtra Pale Malt and 0.3 lbs of Briess 2-row Brewers Malt, along with brewing salts + acid to hit a mash pH of 5.57. The grains were from the same 55 lb sack of each malt. I mashed for 1 hour at 149F, followed by a ramp up to 168F for a 10 min mash out. I mashed 3 different batches: 1) Full volume mash, no recirc, 2) Full volume mash with recirc, 3) Loose mash with 2.4 qt/lb with recirc followed by 1.5 gal sparge poured through the mash basket while up on its posts. The mash efficiency difference was striking. The full volume mash without recirc achieved 72%, with recirc it increased to 74%, and the recirc + sparge reached 87%. From this data, it would appear that the sparge made a significant effect. Unfortunately, I didn’t have enough of the same batch of grain to do a 4th combination of no recirc + sparge.

I used a simple mash of 5 lbs of Viking Xtra Pale Malt and 0.3 lbs of Briess 2-row Brewers Malt, along with brewing salts + acid to hit a mash pH of 5.57. The grains were from the same 55 lb sack of each malt. I mashed for 1 hour at 149F, followed by a ramp up to 168F for a 10 min mash out. I mashed 3 different batches: 1) Full volume mash, no recirc, 2) Full volume mash with recirc, 3) Loose mash with 2.4 qt/lb with recirc followed by 1.5 gal sparge poured through the mash basket while up on its posts. The mash efficiency difference was striking. The full volume mash without recirc achieved 72%, with recirc it increased to 74%, and the recirc + sparge reached 87%. From this data, it would appear that the sparge made a significant effect. Unfortunately, I didn’t have enough of the same batch of grain to do a 4th combination of no recirc + sparge.

Similar threads

- Replies

- 6

- Views

- 424

- Replies

- 46

- Views

- 13K

- Replies

- 46

- Views

- 16K