stickyfinger

Well-Known Member

I saw in an earlier post that you used the FermFast glucoamylase, a 10g packet, how much wort was there? Also curious what your OG was and yeast used?

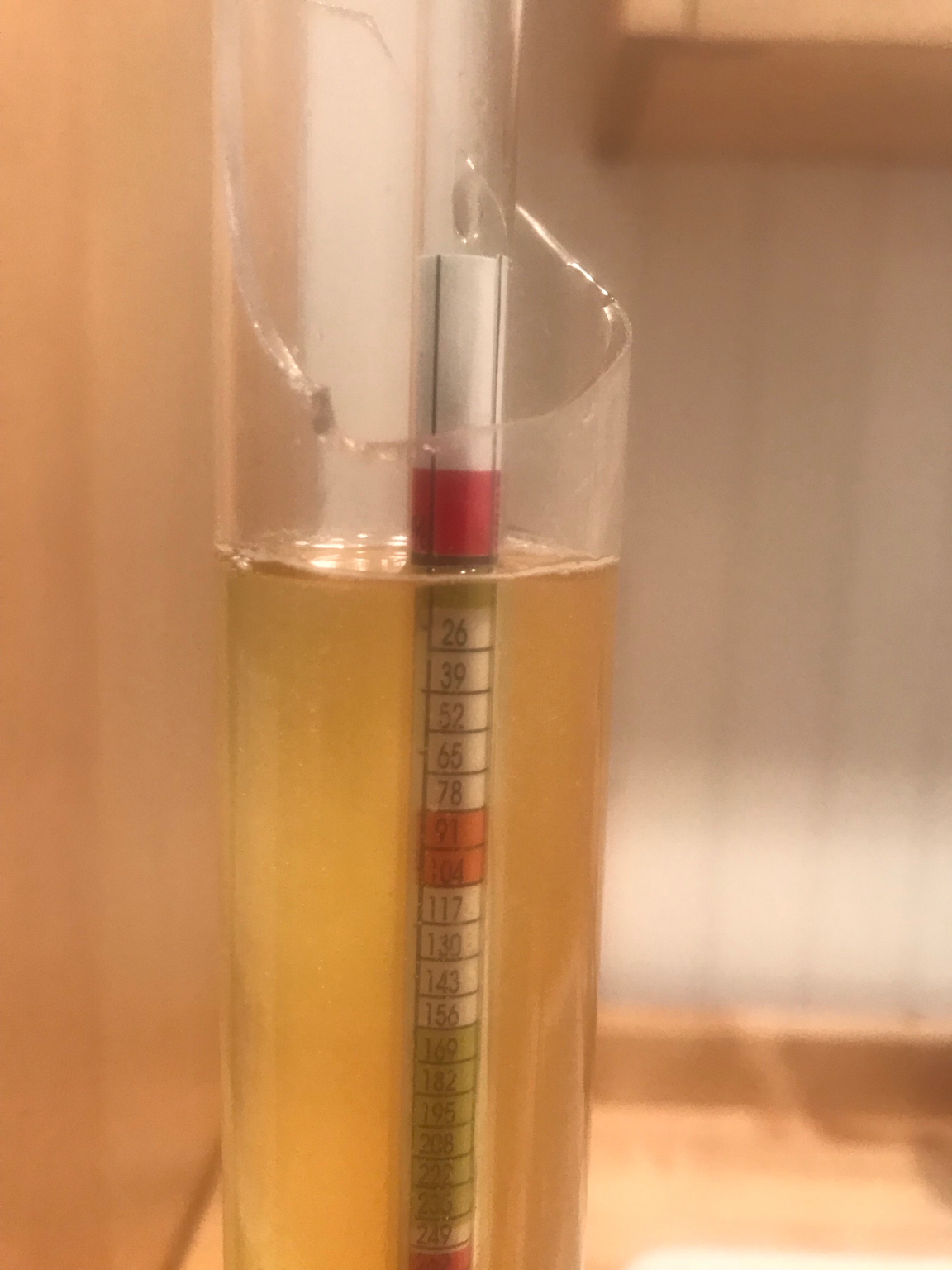

i had 19 gallons of wort and used about 8g of the enzyme. it was a club brew and my friend’s daughter wanted to add it but she spilled some lol. i only added it to the kettle so that everyone could take advantage of some enzymatic activity with their share of wort. the pH is better for the enzyme in the fermenter - probably why it isnt as good in the kettle.

my OG was 1.049. my friend fermented his share (undiluted) which was closer to 1.070-something. He also stopped at 1.004. He used US05. I used DryHop from Imperial.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)