Morrey

Well-Known Member

As we forge ahead with a relatively new process to most homebrewers, we seem to have areas of discovery ahead. As @doug293cz questioned (paraphrasing him), how do we know or predict what level of dryness an enzyme will take us if we just added in the mash and denatured afterward? Is there a way to predict or a certain amount to use??

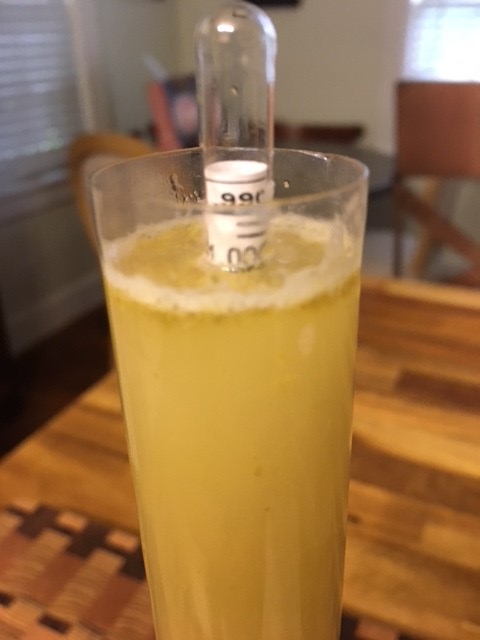

My final FG is .997. This is dry for sure. With cider this low, I add sorbate and do some back sweetening. @doug293cz suggested to consider blending another beer of similar qualities with a higher FG. I like this idea, and @cheesebach made other good points to consider.

I mashed at 148F for 90 minutes. Stirred at the 30 minute mark and temp was at 146.5F (safe zone) so I added 2 ml AMYL-GL. NOTES: Higher than my normal mash conversion efficiency, also, expected 1.050 and got 1.056. Was this a result of the enzyme? Then on to the boil at 90 min which denatured the enzyme.

Question: Is there any way I could "predict" my FG with a controlled dosage of enzyme followed by denaturing?

However, I kept going with the enzyme. After the boil, WP and hopping, I dropped temps down to 130F and added 3 ml more AMYL-GL. This addition never got denatured as it went into FV and remained to work the entire time in FV. NOTE: 5ml of enzyme is the suggested total dosage so I split it between the mash and then the FV.

Should I only add into the mash? How much? How do I predict other than experience?

My final FG is .997. This is dry for sure. With cider this low, I add sorbate and do some back sweetening. @doug293cz suggested to consider blending another beer of similar qualities with a higher FG. I like this idea, and @cheesebach made other good points to consider.

I mashed at 148F for 90 minutes. Stirred at the 30 minute mark and temp was at 146.5F (safe zone) so I added 2 ml AMYL-GL. NOTES: Higher than my normal mash conversion efficiency, also, expected 1.050 and got 1.056. Was this a result of the enzyme? Then on to the boil at 90 min which denatured the enzyme.

Question: Is there any way I could "predict" my FG with a controlled dosage of enzyme followed by denaturing?

However, I kept going with the enzyme. After the boil, WP and hopping, I dropped temps down to 130F and added 3 ml more AMYL-GL. This addition never got denatured as it went into FV and remained to work the entire time in FV. NOTE: 5ml of enzyme is the suggested total dosage so I split it between the mash and then the FV.

Should I only add into the mash? How much? How do I predict other than experience?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)