cactusgarrett

Well-Known Member

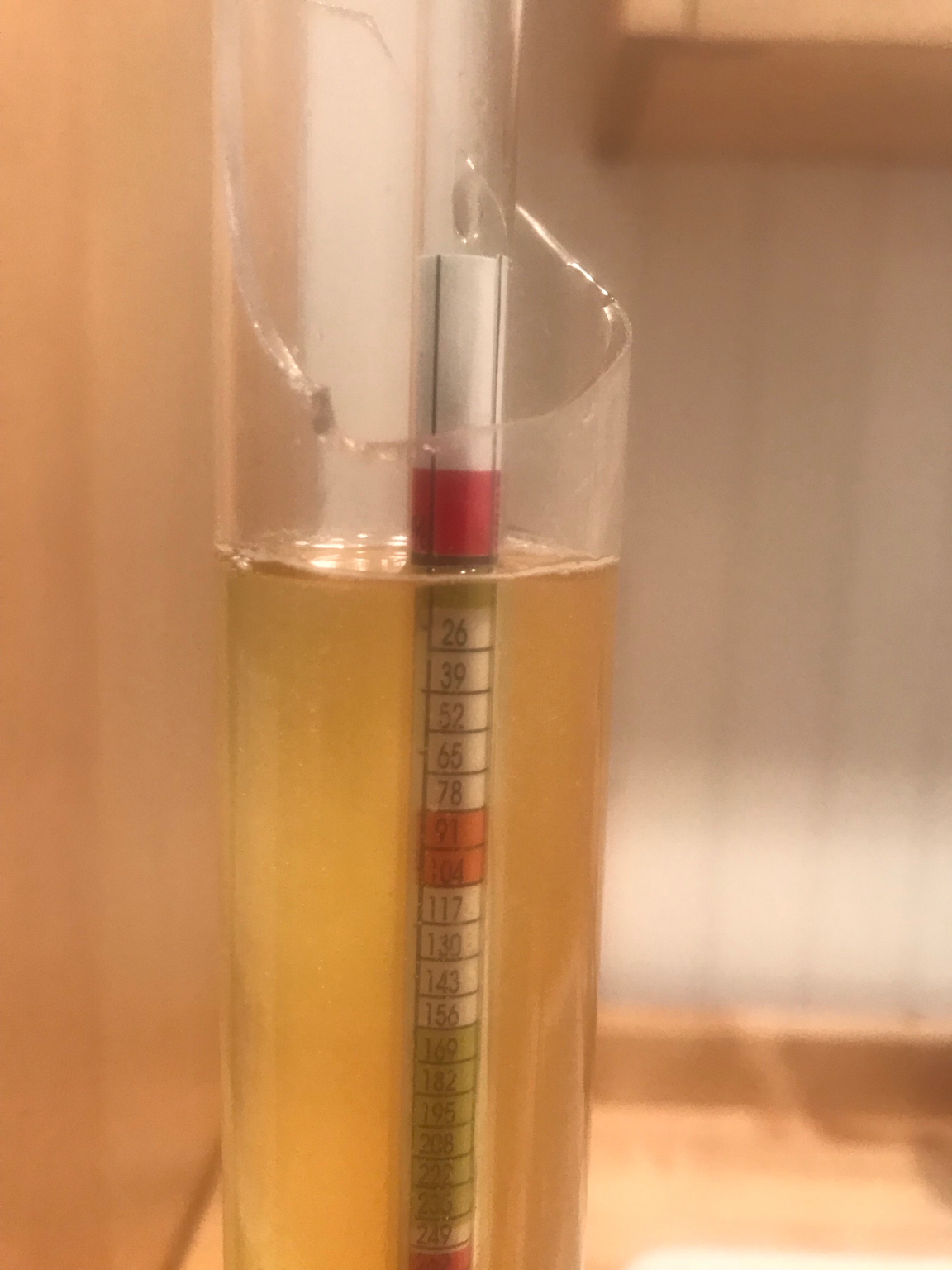

If you're worried, you can hedge your bets and toss some enzyme in the fermenter on the back end of fermentation. I would bet it'd work better there than the mash/kettle, if had to pick one versus the other.Just a follow up...I pitched 4days ago, krausen is almost dropped so I took a gravity reading. Dropped from 1.054 to 1.010, tastes a lil sweet yet. I know it’s got a few points to go, but I wouldn’t expect this sweetness at 1.010, it’s almost like there’s lactose in it. Maybe the glucoamylase broke it down to something the WLP007 can’t fully ferment? Anyway, the glucoamylase did it’s job hopefully the yeast finish its job as well...targeting 1.000-1.002 and already at 81% attenuation.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)