I'm sorry to hear that Seatazz. I really hope that they keep you on and if they don't that you land an even better gig somewhere else. Good luck, these are crazy times.

John

John

This stinks, and training your replacement just adds insult to injury. I’m gonna send some good vibes your way that your next gig is even better for you.Gonna drink a LOT of homebrew tonight. To make a long story short, two years ago the owner of the company I work for (originally a small air/ocean freight concern with offices in Seatac, Kent, Portland, and Vancouver BC) sold us to a huge conglomerate super-corporation that hadn't (and still doesn't) any idea of how ocean freight works. I've been a container dispatcher for 13 years, and I'm pretty damn good at it. Fast forward a couple years, and we're not making the money they expected; add the coronavirus kerfluffle and about 70% of our staff was laid off, with the rest of us expected to take on more responsibilities. I'm salary; expected to work longer hours so the hourly folks can work shorter hours. I'm not the complaining sort, I gladly took on more work to save the company. The manager (former owner), has other ideas now and apparently my job is on the line, based on some issues over the last few weeks that I had little to no control over. I was told today to fast-track training of my new supervisor on how to do my job; being in the workforce as long as I have, I know what that means. Get her trained, and they can get rid of me.

I know I can find another job (have a few tentative offers on the table) but at 52 it's hard to change. So tonight, with the husband at the pub playing cards with his buddies, I'm going to let my homebrew do what it does best; get me schnockered. And since I no longer work my second job, which had the constant threat of random drug tests hovering over my head, I might also pay a visit to our neighborhood "green" store tomorrow night. Gonna be a weird weekend.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Came home after a wonderful (sarcasm level 10000) day at work with the idea of putting the Irish Death on tap; took the American strong off to accommodate it. As soon as I pulled the co2 connect off that keg I got the dreaded fwoosh of offgassing; yet ANOTHER failed poppit. Fortunately @BobbyM got my order here in record time, and I have plenty of new poppits to replace it; except I apparently installed this post with my impact wrench (not really) and I can't get it loose; no worries, just grab said impact wrench and gently try to turn it. Except the battery is dead. Arrrrrgh. And the 20lb co2 tank that I got when I bought the kegerator is starting to, well, tank. I have a full 5lb as backup but I don't want to put it on if I don't have to. Oh well, at least there's still IPA and Wit....

I brewed a kind of brown-stout ale, dark in color but not roasty at all that I will be inoculating with the air in my garden, under a kind of tent where I usually drink my beer (including some lambics) and next to my neighbor's fruit trees, so the place is promising and so is the ambient temperature today, it might rain during the night but my hopes are that the tent will have enough residents in it plus all the stuff the wind is bringing now from the surroundings, maybe if I'm lucky something will come flying from the vineyards

After life happening for the last few weeks I am coming back strong with a double brew day. A “light” lager and a mixed-ferm table saison are on the list for today.

Hopefully my Anvil Foundry will be here in a week or two and I can brew my first full batch of beer now that I have a kegging system waiting on it!

Darn it, I hope so. 20lb exchange where I go is about $28, and I really don't want to have to get it exchanged again. Half tempted to turn the gas off when I go to bed tonight just in case, but I'm paranoid now. I don't like messing around with co2 (or electricity either) but sometimes needs must.@seatazzz, Sounds like you may have found your leak. Always nice when a sneaky problem becomes easy to spot.

I have 50/50 luck with ambient bugs: the grapes from my garden gave good bugs and all of my sours use that culture, on the other hand, I received a sour culture from a pro brewery that had 300+gallons going in a foeder and after two years of waiting it still tasted like a$$. I wish you the best!

Amen to that Hoppy! Tazz, life is full of doors. For each door that closes, another door opens to rooms full of Windows of opportunities! Hang tough!This stinks, and training your replacement just adds insult to injury. I’m gonna send some good vibes your way that your next gig is even better for you.

The wife had caught another cup and I mopped up nearly as much, so it looks like the loss was under a quart. An hour more cleaning, pulling the drain tubing off my drip tray and rinser and cleaning them bright again, draining and cleaning the catch keg, updating my tap list to account for the lost stout, and we were back in bidness.

The wife had caught another cup and I mopped up nearly as much, so it looks like the loss was under a quart. An hour more cleaning, pulling the drain tubing off my drip tray and rinser and cleaning them bright again, draining and cleaning the catch keg, updating my tap list to account for the lost stout, and we were back in bidness.

Gotta love a happy ending.Today...mostly due to stupid luck, I saved a keg of imperial chocolate stout from disaster.

During the week my normal "first pour" typically happens at the stroke of 5pm by intent. But today I was cleaning up after priming the east end of the house, and didn't get to the brewery until 5:13 - when I discovered the stout bubbling up through the handle end of my Micromatic stout faucet! WTH! And YIKES!

Immediately called The Spousal Unit down for emergency assistance as I observed my stout was slowly disappearing down through the drip tray drain into the 3 gallon catch keg inside the keezer. Good it wasn't all over the place - bad that I had no idea how much stout had already been lost.

First instinct was to pull the handle and let it snap back hoping it would seal up tight. A really bad move - instantly the leak rate easily tripled, now flowing at around a quarter-ounce per second. I had the wife hold a 1/2 gallon plastic bucket under the faucet while I used a shop towel to soak up enough of the stout still in the tray to lift the keezer lid just enough to reach in and pop the beer QD off the stout keg.

Flow then stopped, we mopped up the keezer top so I could open the lid fully. I pulled the catch keg and discovered there was barely a cup of stout therein!The wife had caught another cup and I mopped up nearly as much, so it looks like the loss was under a quart. An hour more cleaning, pulling the drain tubing off my drip tray and rinser and cleaning them bright again, draining and cleaning the catch keg, updating my tap list to account for the lost stout, and we were back in bidness.

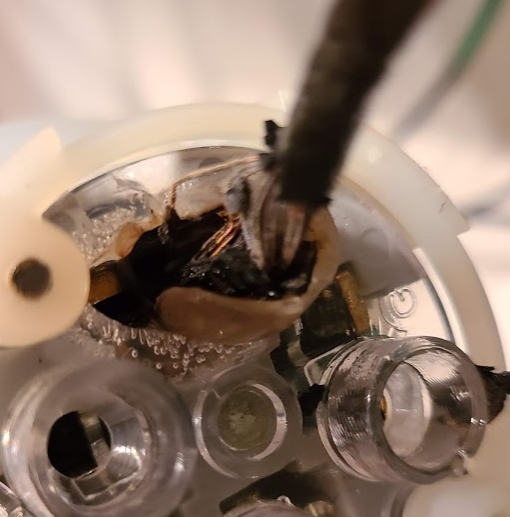

I pulled the Micromatic faucet and took it apart. This diaphragm is the culprit...

View attachment 685324

Right at the seam between the bottom tapered section and the immediately adjacent reversed taper above there's a breach. Clearly fatigue failure.

It's a $5 part direct from Micromatic (and I bought two) but it'll likely take most of a week to get here. I stuck my 6th 525ss Perl in its place for the time being but will probably have to drop the nitro pressure waaaaay down to get a tame pour out of it

Could have been so much worse though - like, if it had happened at any other time of the day. That keg had over 4 gallons in it last night, my catch keg is only 3 gallons, and once that is full and the drip tray overflows there would be an epic mess...not to mention a tragic loss of my nitecap for a month. That would be "double-plus ungood!"

I'm now trying to remember how many years I've been running this faucet so I can hopefully PM that diaphragm well before it fails. Kinda like the timing belt on an interference engine, if it fails it's catastrophic. Pretty sure it's at least 8 or 9 years old...

Cheers!

So you collect magnets? I collect coasters that I turn into magnets, most of them are Belgian but I'm trying to include more national (Spain) onesSWMBO went to her LCS (Local Craft Store) and picked up a page of magnet material for me, so...

View attachment 685303

On the carpet! If my wife..... You are very brave... CudosGot the double tap tower set up, had to improvise, Arctic King has some weird twist lock where the tower goes, had to drill and hope and pray nothing important was running through the top! Got the beer transferred to kegs, just 30 lbs pressure and let it chill down to 45° over next 24 hours then carb up with the quick carb lids. Wooooohoooo!!!View attachment 685473View attachment 685474

Actually she was giving me a come to Jesus evil eye kind of look!On the carpet! If my wife..... You are very brave... Cudos

I know I checked for leaks yesterday with soapy sudsey water...lost 1/2 of my co2 Damn it @!#%#!÷. Rechecked and was leaking at the regulator connect. Seems to be ok now. Holding steady at 12 pounds pressure to carb. Put up my metal beer wall art, wife is taking it hard...officially a beer cave now!

!!