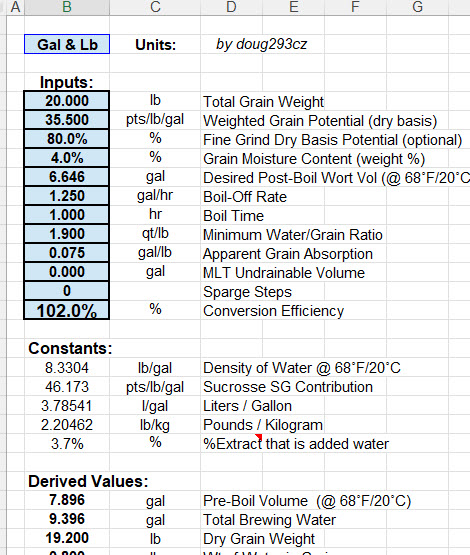

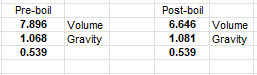

While most of my recipes have a conversion efficiency in the near 93-100% range, there are a few outlier recipes that were 102%. My thoughts are that one or more of the mashed grains had a higher than expected starch contribution, or possibly the result is due to a plus or minus 2% error factor.

Are there other explanations for getting higher than 100% conversion efficiency?

Are there other explanations for getting higher than 100% conversion efficiency?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)