CSI - CandiSyrup

Well-Known Member

If we're after a BLAM spec for color and flavor D-180 would be the better choice for the Westvleteren 12 so you're probably in great shape.

I can honestly say my beers using wlp530 got a little better, but i get a more noticeable belgian character using wlp500 and wlp570 the 500 more fruity and the 570 more spicy. I am going to try 530 one more time. If i am not happy with it i may try a blend of the 500 and 570 next time

Sent from my iPhone using Home Brew

Good to know.

This is my first time brewing it. I'm not opposed to a mellower beer, in fact I prefer that. I'm just trying to figure out if I made a mistake.

It's a lot easier when you can do a side-by-side taste test. I was hoping for a reference point from someone who's had the real deal. I won't be dropping $40 for a bottle anytime soon.

It's not per the recipe, but I used 2 lbs of the D180 and 1 lb of the D90. I would guess there are mostly overlaps in terms of taste between the two, but some sublte differences as well.

BTW, I love the taste that I ended up with. I don't think you will be disappointed with the D180. I beleive the sugar PPG is the same for D90 and D180.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

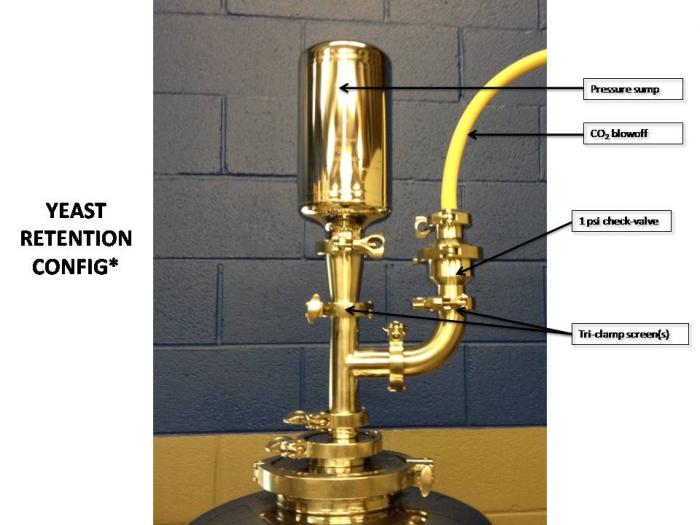

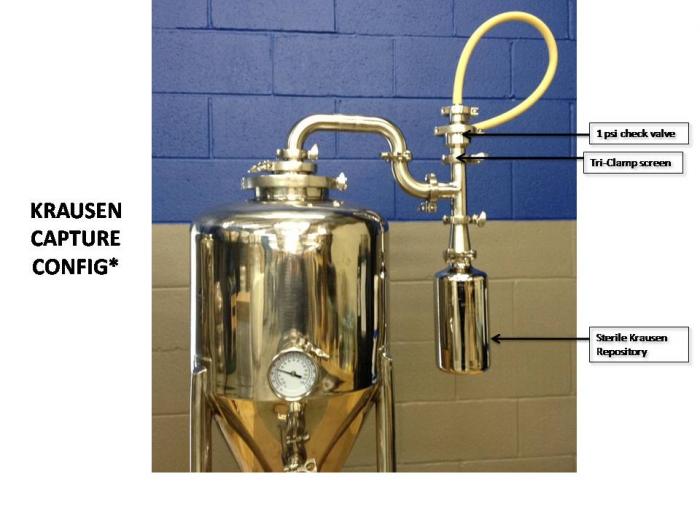

This is the harvest configuration. This is completely sealed and sterile for clean krausen capture.

Is something like this available on the market for purchase or was it a custom fabrication to fit on the conical? I'm just using buckets and top cropping for harvest but would like to jump to a conical with more harvesting options. I like the top crop more for the yeast health but finding a way to do it with a conical is the goal to work for.

Sent from my Galaxy Nexus using Home Brew mobile app

We've been tinkering with subtle changes with the Westvleteren 12 clone for just over 4 years now. This is a snapshot of highlights we've learned to date:

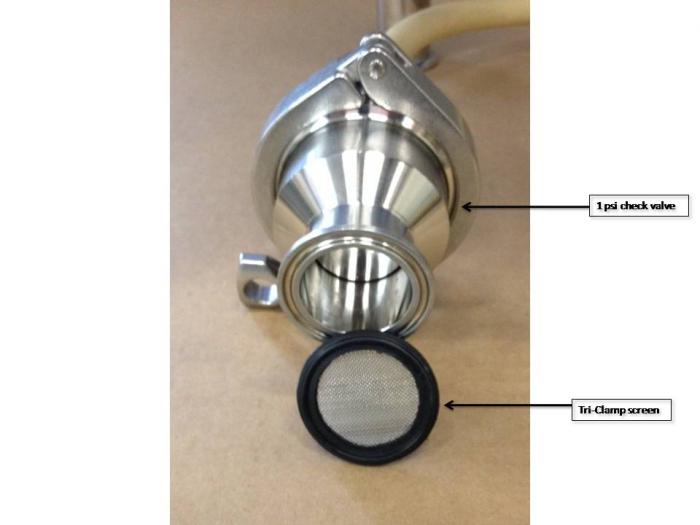

To my knowledge there is nothing on the market like this. It can be assembled with a combination of tri-clamp components (tri-clamp Eagle stainless bottle, reducer, stainless check valve, elbows, and T's). We also have a sight glass for viewing krausen flow that sits on the top of the fermentor (not pictured). There is one Belgian Brewery doing something similar which we modified for our testing fermenters, (17.5gal). The key need for us was to create a sealed system for a sterile yeast harvest. I forgot the total cost but it pays for itself quickly in krausen harvest.

Edit: for the Westmalle strain we harvest from a Westmalle Extra brew. A good harvest is about 350-400 grams of refreshed krausen.

What company manufactured the conical you are using in the photos?

CSI -

Have you compiled this into a new recipe?

What company manufactured the conical you are using in the photos?

I think brewer's hardware (and many others) buy from Chinese manufacturers and resell. There are some US manufacturers that you can choose if you want to. It is important to me to support sanitary pipers and welders in the US, but might not be important to others (no judging, just throwing it out there.)

I think whiskey barrel aging would make an interesting beer, but I don't really think it's appropriate for this beer. Try brewing the original recipe once and see if you think barrel aging would add to the effect. I can't see it enhancing the beer, just muddying flavors.

Sent from my iPad using Home Brew

Great thread! I'm planning on doing the Old World Version this week. Coincidentally, I have a Balcones Whisky Barrel on the way. Any thoughts on aging this beer in a whisk(e)y barrel? Pros, cons?

Thanks,

Mike

If doing the Old World you may consider holding back on the Belgian Pale by about 50% and replace it with Pils....closer to the actual Westy 12 this way.

Thanks, I'm actually using the recipe on your site.

working within my limited means as an overseas brewer with limited access to pro-quality ingredients...

There are several US home-brew stores that will ship yeast with cold packs - if you buy a few vials and have them shipped to where you live would that be economical?

With typically two weeks or longer of transit time, I'm not so certain the ice packs would hold out for a shipment to China. We've got a guy in Shanghai who imports liquid yeast and keeps some in stock or can import it on demand (very possibly the same as you're suggesting), but he charges about $25/vial and while I know he keeps it refrigerated, I'm not sure how fresh it would be when it got to me.

If I had a stir plate and flask, and a pressure cooker for slanting and/or a larger fridge/freezer for storing slants/extra slurry from starters, I would probably start building a collection, but the fact is that I'm in an apartment with a fridge that's about 25% too small for our food needs already, and with the exception of this proposed brew, I'm still a total yeast novice - pitching rehydrated dry yeast or, if I'm living on the edge, pitching on a yeast cake is all I've really needed to do so far.

One day, I hope to be as obsessed and knowledgeable as the old hands here on the forum, but for now, I'm a six-months-of-experience, dry yeast, feed-grade malt, BIAB sort of guy. I know that's not a very promising profile for someone trying to make anything even close to a Westy 12 clone, but barring a dump-worthy infection, the worst case scenario is that I'll end up with beer, and I'm willing to risk that.

CSI, you mentioned before about doing a repitch at bottling time using fresh krausen. I won't be able to do so, but I will be able to make a small starter to pitch. What yeast count do you recommend for this at pitching?

Hey,

I'm 8 days into fermentation and this beer still has vigorous activity happening! Still has a thick krausen and is bubbling like crazy!

OG was 1.083 (a little low because I didn't boil down enough), I cooled the wort down to 63 degrees and pitched a 1.5 litter starter of 3787. Held at 66 degrees for 2 days, 68 for 2 days, 70 for 2 days, and is now currently at 72 degrees. I had high krausen by day 2 and needed a blow off tube for 5 days.

I normally don't worry about these things, but 8 days after pitching yeast I still have a ton of activity going on. I've never really seen that before. I'm not sure if I should start to cool this down or keep it at 72 degrees? Any help/ideas?

Thanks,

Mike

The only thing I am normally concerned about is drying out the ale too much. If you hit 1.013 and you still have activity, crash it for 3-4 days way down to 35-40F and dump the primary yeast cake. Hitting FG is important enough to go to the trouble of an early crash.

So its ok to stop primary fermentation early? Lets say the beer can ferment down to 1.010 and you stop it at 1.013 by crashing and or moving vessels. I was under the assumption that after sugar is consumed the yeast clean up off flavors. Is this true?

yup, i'm with you on that one. you should control your FG by recipe and process before fermentation, not by artificially stopping fermentation mid-way through.

If it looks like you're going to miss your target FG, fix it in the next batch. don't ruin the current batch by stopping the yeast in their tracks, before they've had time to re-absorbe diacetyl, accetylaldehyde, etc.

I second what sweetcell is saying, I undershot gravity the first time trying the old world traditional recipe and let it ferment down completely (holding temp) it stopped at like 1.003. This beer had enough complexity to it (and quite a bit dry) but at six months it is a close cousin in a head to head tasting to the original. I would have preferred to hit my targets but I'd rather still have an excellent beer at the end of the day! That same beer just took first in the World Cup of beers for the Belgian strong ale style!

Sent from my iPhone using Home Brew

So if you end up with a low FG like above its best to mash higher next time? I did a belgian with a 20% sugar addition fermented around 156 to try to get fg around 1.014 and it stopped at 1.025

Sent from my iPhone using Home Brew