clamp over float valve.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Spike Solo Owner's Thread

- Thread starter RichardU

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Punx Clever

Well-Known Member

- Joined

- Nov 27, 2007

- Messages

- 495

- Reaction score

- 575

Ho do you guys with solos and RO water filters fill the kettle?

Before brew day?

Just check on it every so often?

Day before. I get 4-6 gph out of my RO unit. Usually brew on Saturdays, so get home from work on Friday, set up system, start filling water, check on it every couple of hours while I do chores, cook dinner, etc.

Day before. I get 4-6 gph out of my RO unit. Usually brew on Saturdays, so get home from work on Friday, set up system, start filling water, check on it every couple of hours while I do chores, cook dinner, etc.

View attachment 723992

This is a recipe for a flood. If it hasn't happened yet, you've just been lucky but you will one day get distracted.

$5 float valve Plastic Float Valve For Reverse Osmosis RO System#SP-FV

$18 stainless clamp over mount (or make something DIY) PT-FVBS Stainless adjustable Float valve bracket kit small

As someone who recently flooded my laundry room/ with probably 25-50gallons of water while filling a 5 gallon cube, that inevitably leaked into my basement, I would have gladly payed the $23 mentioned here to not have to do that clean up, removal of drywall in my basement ceiling, etc.This is a recipe for a flood. If it hasn't happened yet, you've just been lucky but you will one day get distracted.

$5 float valve Plastic Float Valve For Reverse Osmosis RO System#SP-FV

$18 stainless clamp over mount (or make something DIY) PT-FVBS Stainless adjustable Float valve bracket kit small

I'm not going to lie, but that foil wrapped 240V plug has me worried for you man. I would consider wrapping that in something that isn't conductive if you're worried about getting anything on the plug.Brewed yesterday and loved the solo.

Of course, I totally screwed up right from the start of brewing. Up until 3 batches ago I've just had my lhbs mill my grains and then I come directly home and dump em into my waiting prepped/heated mash water. Been doing this for 8 years now.

So, naturally I dumped 2/3 of the grain in and then realized what I had done, stopped, and pulled the basket out.

I actually laughed. I milled the dry grains I had and then milled the soggy grains too. It looked like it sorta "hurt" the grains but they were far from correctly milled. I then proceeded with my brew day.

63% mash efficiency.

This doesn't mean anything to me tho and I look forward to finding out what kinda numbers I hit with a real crush.

That said I ended up at 1.053 after the boil rather than the beersmith predicted 1.063.

Beersmith was, however, DEAD on with all water/wort volumes. 6 gallons into the fermenter almost exactly.

Because 2/3 of my grains were merely bruised u had no issue with stuck recirculation.

The mash temp was consistently 2⁰F lower than what the solo was reading. This made it easy as I just turned up the solo controller 2⁰. I continued to check temps during the mash, but don't think it'll be necessary in the future.

You know, I honestly just wasn't thinking straight. I had it sitting on the table and it was the right size, so I just laid it on there. Bad move.As someone who recently flooded my laundry room/ with probably 25-50gallons of water while filling a 5 gallon cube, that inevitably leaked into my basement, I would have gladly payed the $23 mentioned here to not have to do that clean up, removal of drywall in my basement ceiling, etc.

I'm not going to lie, but that foil wrapped 240V plug has me worried for you man. I would consider wrapping that in something that isn't conductive if you're worried about getting anything on the plug.

You're a real homebrewing hero. That is the elegant solution I was hoping existed.This is a recipe for a flood. If it hasn't happened yet, you've just been lucky but you will one day get distracted.

$5 float valve Plastic Float Valve For Reverse Osmosis RO System#SP-FV

$18 stainless clamp over mount (or make something DIY) PT-FVBS Stainless adjustable Float valve bracket kit small

Last edited:

Punx Clever

Well-Known Member

- Joined

- Nov 27, 2007

- Messages

- 495

- Reaction score

- 575

This is a recipe for a flood. If it hasn't happened yet, you've just been lucky but you will one day get distracted.

Based on that, I suspect that you'd also say that checking on my smoker every couple hours or so while cooking up a brisket is a recipe for a catastrophic fire.

Nah, I disagree. I took the time to figure out what my production rate is on my RO system and check on it several times throughout the fill to confirm liquid level and production rate. At ~5gph with final volumes between 14 and 20 gallons it is plenty safe.

I have no trouble keeping track of multiple processes at the same time, especially when one of them is relatively slow, like a home-brew scale RO system.

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$33.98

DYKWSWYX Heavy Duty Brewing Gloves (1 Pair) - 55CM Long Chemical Resistant Plastic Gloves for Beer & Wine Making, Cleaning, Homebrew Equipment Protection

wuhanshijiayangzhiyimaoyiyouxiangongsi

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

Based on that, I suspect that you'd also say that checking on my smoker every couple hours or so while cooking up a brisket is a recipe for a catastrophic fire.

Nah, I disagree. I took the time to figure out what my production rate is on my RO system and check on it several times throughout the fill to confirm liquid level and production rate. At ~5gph with final volumes between 14 and 20 gallons it is plenty safe.

I have no trouble keeping track of multiple processes at the same time, especially when one of them is relatively slow, like a home-brew scale RO system.

I dont have any opinions on what you do with your smoker. Every person I know that once collected brewing RO like you are doing has flooded some room at least once. Knowing there is a less risky way to do it, for a small investment, but not doing it doesnt make you brave.

Oceangrace24

Well-Known Member

I've already sent Spike an email asking for advice, but I thought I would ask everyone here in case someone might know what is going on.

My Solo+ system arrived today. I had my electrician friend over to install the 240 circuit to run the system.

I have a shed that I am brewing in that has a subpanel feeding from the garage.

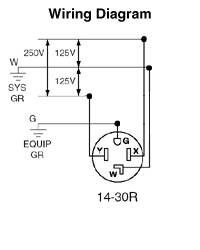

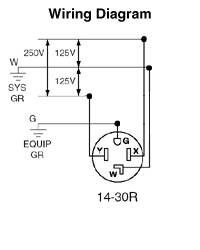

He ran 10/3 wire from the subpanel to a 50amp Spa Panel so we could have the GFCI breaker in the spa panel.

Connected the Spa Panel to a 14-30 outlet.

He plugged in the controller and with everything turned on, he tested all the outlets on the Panel with a meter.

The problem is that we are showing 240v out of the pump and Acc outlet. The outlet for the Element is showing 120v.

These should be reversed, correct? Did he wire something incorrectly between the subpanel, spa panel and outlet, or is there something wrong with the controller?

My Solo+ system arrived today. I had my electrician friend over to install the 240 circuit to run the system.

I have a shed that I am brewing in that has a subpanel feeding from the garage.

He ran 10/3 wire from the subpanel to a 50amp Spa Panel so we could have the GFCI breaker in the spa panel.

Connected the Spa Panel to a 14-30 outlet.

He plugged in the controller and with everything turned on, he tested all the outlets on the Panel with a meter.

The problem is that we are showing 240v out of the pump and Acc outlet. The outlet for the Element is showing 120v.

These should be reversed, correct? Did he wire something incorrectly between the subpanel, spa panel and outlet, or is there something wrong with the controller?

10/3 Romex or some kind of SJ cord? If it was romex, that would be correctly 4 wires. If not, you need 4 wires to feed 14-30.

Oceangrace24

Well-Known Member

10/3 romex is what was used.

The reasonable explanation is that somewhere a hot and neutral got flipped and that can be in your wiring or in the controller box itself. Start by probing your 14-30 receptacle with a volt meter. This is what you should get. 240v between the left and right. 120v between the top and either left or right and also 120v between the bottom and either left or right. Posting each of your readings in all those scenarios, if it's not as I described, can reveal how it's mixed up.

Oceangrace24

Well-Known Member

We did all that and got the correct readings for each part. That means it has to be in the control panel I guess? Hopefully Spike has an answer tomorrow.

Spike will likely want to swap the controller out for you but it would be easy enough to trace the lines to figure out where it went wrong. It may be right on the line input socket. I guess it depends on your patience.

vindee

Well-Known Member

Almost sounds like without a neutral to the controller you will have unpredictable results. You will need neutral for proper 120 volts and the ground for obvious reasons.I've already sent Spike an email asking for advice, but I thought I would ask everyone here in case someone might know what is going on.

My Solo+ system arrived today. I had my electrician friend over to install the 240 circuit to run the system.

I have a shed that I am brewing in that has a subpanel feeding from the garage.

He ran 10/3 wire from the subpanel to a 50amp Spa Panel so we could have the GFCI breaker in the spa panel.

Connected the Spa Panel to a 14-30 outlet.

He plugged in the controller and with everything turned on, he tested all the outlets on the Panel with a meter.

The problem is that we are showing 240v out of the pump and Acc outlet. The outlet for the Element is showing 120v.

These should be reversed, correct? Did he wire something incorrectly between the subpanel, spa panel and outlet, or is there something wrong with the controller?

Spike will tell you you need to run 4-wire for this setup.

EDIT: I didn't read everything here. If you ran 10/3 with a ground then your cabling is good. Refer to the other posts here.

Last edited:

- Joined

- Apr 7, 2021

- Messages

- 56

- Reaction score

- 48

I have brewed 13 batches in my Solo with a Spike condenser lid. The learning curve was steep, but my process is now repeatable and under control. OG and FG are matching Brewsmith’s estimates exactly (that’s probably luck, not skill). I get a very pronounced trub cone in the whirlpool. My wort is clear with little or no grain. My mash doesn’t get stuck. My efficiency is equal to my old picnic cooler setup. Brewing indoors out of the wind and weather makes brew day a lot more pleasant. Cleanup is easy...not fun...but easy. All in all, this is a fantastic piece of equipment that works great. I am down to one remaining issue...or it may not really be an issue at all. I get a lot more foaming with the condenser lid than I used to with an open brew kettle. This causes a lot of hop matter to stick to the side of the brew kettle just above the wort level. Does anybody else have this problem? Is it even a problem? Is there a solution if it is a problem? My beer tastes better than ever so that might be the answer. Thanks, everybody, who posts on this forum. Your ideas, observations, and knowledge are a big help.

user 295610

Active Member

- Joined

- Dec 28, 2020

- Messages

- 33

- Reaction score

- 10

I've only done four batches with my condensing lid, but I'm able to turn the PID down to 28% and still keep a rolling boil without any foam. What are you setting your PID at after you get a boil?I have brewed 13 batches in my Solo with a Spike condenser lid. The learning curve was steep, but my process is now repeatable and under control. OG and FG are matching Brewsmith’s estimates exactly (that’s probably luck, not skill). I get a very pronounced trub cone in the whirlpool. My wort is clear with little or no grain. My mash doesn’t get stuck. My efficiency is equal to my old picnic cooler setup. Brewing indoors out of the wind and weather makes brew day a lot more pleasant. Cleanup is easy...not fun...but easy. All in all, this is a fantastic piece of equipment that works great. I am down to one remaining issue...or it may not really be an issue at all. I get a lot more foaming with the condenser lid than I used to with an open brew kettle. This causes a lot of hop matter to stick to the side of the brew kettle just above the wort level. Does anybody else have this problem? Is it even a problem? Is there a solution if it is a problem? My beer tastes better than ever so that might be the answer. Thanks, everybody, who posts on this forum. Your ideas, observations, and knowledge are a big help.

- Joined

- Apr 7, 2021

- Messages

- 56

- Reaction score

- 48

I’m at 60% power in manual mode once the boil gets started. Do you know your evaporation rate at 28% power? I measured mine and am at 1.25 gallons per hour at 60%. Reducing power further sounds like a good thing to try. Thanks!I've only done four batches with my condensing lid, but I'm able to turn the PID down to 28% and still keep a rolling boil without any foam. What are you setting your PID at after you get a boil?

user 295610

Active Member

- Joined

- Dec 28, 2020

- Messages

- 33

- Reaction score

- 10

I’m at 60% power in manual mode once the boil gets started. Do you know your evaporation rate at 28% power? I measured mine and am at 1.25 gallons per hour at 60%. Reducing power further sounds like a good thing to try. Thanks!

I have the Solo 10 gallon and the evaporation rate is between 0.5 - 0.6 gal/hr.

Oceangrace24

Well-Known Member

Well, we found the issue with the electrical causing my issues in my controller. My 240 outlet was wired correctly by my electrician.

Spike put me in touch with ebrewsupply. They walked me through opening up the panel. We found that the black hot wire and the white common wire were reversed. Evidently they just hired a new QC person who missed it.

He walked me through changing them back to being correct. Looks like the contactors are most likely blown so they are shipping me out those parts and a couple more to make sure we get everything right.

All the parts inside the controller are all industry standard to make any repairs easier.

While it's a bummer it was not correct, really happy with Spike and Ebrewsupply with the response and help with the issue.

Glad my electrician actually tested the panel or I most likely would have plugged in the pump and fried it and needed a replacement.

Sounds like it was just a one off incident.

Hope to be brewing soon!

Spike put me in touch with ebrewsupply. They walked me through opening up the panel. We found that the black hot wire and the white common wire were reversed. Evidently they just hired a new QC person who missed it.

He walked me through changing them back to being correct. Looks like the contactors are most likely blown so they are shipping me out those parts and a couple more to make sure we get everything right.

All the parts inside the controller are all industry standard to make any repairs easier.

While it's a bummer it was not correct, really happy with Spike and Ebrewsupply with the response and help with the issue.

Glad my electrician actually tested the panel or I most likely would have plugged in the pump and fried it and needed a replacement.

Sounds like it was just a one off incident.

Hope to be brewing soon!

Switchback

Member

- Joined

- Jul 5, 2020

- Messages

- 15

- Reaction score

- 3

How did you get the Blichmann autosparge connected to the triclamp basket? I just ordered a Solo 15 and would like to do that but haven't figured on the connections yet.That was something I experienced too. Got set up to use the Blichmann AutoSparge from my 3v system in the basket... no more over-run mash for me.

That's 40lbs of grain to run a partigyle for 5g of Rye Wine and 10g of Rye Mild. I've use loc-line off of the autosparge for smaller grain bills, but this was a good picture of how it sits in the basket.

Oceangrace24

Well-Known Member

How is it going with everyone regarding mash temperatures and consistency?

One of my top reasons for making the jump to electric was for mash temperatures. I want to be able to control my mash as precisely as possible. I want to be able to mash a beer at 152° and then turn around and mash the same recipe at 154° to see the difference and so forth.

I read some early posts about the temperature being off between the temp probe and the middle of the grain bed.

Just wondering if anyone has made any progress on getting these more consistent.

Should be brewing here on my new Solo 20 in the next week or so.

One of my top reasons for making the jump to electric was for mash temperatures. I want to be able to control my mash as precisely as possible. I want to be able to mash a beer at 152° and then turn around and mash the same recipe at 154° to see the difference and so forth.

I read some early posts about the temperature being off between the temp probe and the middle of the grain bed.

Just wondering if anyone has made any progress on getting these more consistent.

Should be brewing here on my new Solo 20 in the next week or so.

I've only brewed one batch on my solo, but checked the temperature of the grain bed a few times during the mash and it was consistently 2⁰ lower than the probe read

user 295610

Active Member

- Joined

- Dec 28, 2020

- Messages

- 33

- Reaction score

- 10

Five batches in on my Solo 10, and I think I'm finally starting to hit my stride with the system. Good recirculation is pretty key in controlling the grain bed mash temp. I'm using 0.035" triple roller milled 2-row, adding rice hulls as 3-5% of grain bill, allow grains to sit for 10 minutes before starting the pump, and my recirculation flow has no issues up to 1/4 pump flow rate. My grain bed is also 2 deg below probe temp, but that's because I'm losing 2 deg through the recirculation hosing and pump. But that's easy to compensate for with a bump on the PID temp. All and all, really happy.

Has anyone tried the BrauSupply hop blocker with the Solo?

https://brausupply.com/collections/...s/products/hopblock-filter-plate-and-dip-tube

https://brausupply.com/collections/...s/products/hopblock-filter-plate-and-dip-tube

Attachments

Oceangrace24

Well-Known Member

I didn't buy a CF chiller with my Solo because I have a Jaded Hydra chiller that I plan on using. I read earlier that someone else uses one and they used a hook and some zip ties to hang it from the side to keep it off the element.

Would there be any good reason why I couldn't take the grain basket, clean it out during the boil, and then put it back in the kettle at the end of the boil and set the IC on the bottom of the basket to keep it off the element?

Would there be any good reason why I couldn't take the grain basket, clean it out during the boil, and then put it back in the kettle at the end of the boil and set the IC on the bottom of the basket to keep it off the element?

I didn't buy a CF chiller with my Solo because I have a Jaded Hydra chiller that I plan on using. I read earlier that someone else uses one and they used a hook and some zip ties to hang it from the side to keep it off the element.

Would there be any good reason why I couldn't take the grain basket, clean it out during the boil, and then put it back in the kettle at the end of the boil and set the IC on the bottom of the basket to keep it off the element?

I think that would work. 2 other options I am considering.

https://www.brewhardware.com/product_p/biabbottom17.htm

https://jadedbrewing.com/products/the-electrichair

Oceangrace24

Well-Known Member

I may have to look into one of those options as well. Not sure my chiller will be immersed enough when doing 5 gallon batches, but should be ok for 10 gallons.

Y'all might wanna try a CFC.

I gave it a try and have found that I like using it.

I gave it a try and have found that I like using it.

Oceangrace24

Well-Known Member

I'm sure they are great. But I already had a Jaded IC, so I didn't want to spend the money on something else when I have something that will work well.

Probably a good idea not to try the CFC! I was foolish enough to try the exchilerator and now my Hydra will never get used again. Chilling beer in one pass from ~200F to ~64F as it flows from boiler to fermenter is a game changer.

I’d like to know as well! Maybe you can be the test pilot and let us know.Has anyone tried the BrauSupply hop blocker with the Solo?

https://brausupply.com/collections/...s/products/hopblock-filter-plate-and-dip-tube

I’d like to know as well! Maybe you can be the test pilot and let us know.

Building my new brewery now and I certainly will be the ginny pig if it comes to that. I'm targeting the solo for my brew system but I want to make a number of changes. 1) I want to use the blichmann brew commander, 2) I am looking for a hop filter, Brau Supply is my current target, 3) I want to add the blichmann sparge arm to mitigate the stuck mash / scortched element risk, 4) I am going to get the SS brew cube and side shelf for my stand. Any other ideas?

- Joined

- Apr 7, 2021

- Messages

- 56

- Reaction score

- 48

KVbeer, thank you again for sharing your PID settings. I never would have thought to go that low. After some “dry run” trial and error, I tried 35% (15 gallon Solo, 240 Volt). I hit all of my numbers with zero foam and no hops sticking to the side of the kettle. Win! I see you are living in Maine. I lived in Millinocket for a few years. I was “from away”. Thanks again for the tip. Cheers.I've only done four batches with my condensing lid, but I'm able to turn the PID down to 28% and still keep a rolling boil without any foam. What are you setting your PID at after you get a boil?

user 295610

Active Member

- Joined

- Dec 28, 2020

- Messages

- 33

- Reaction score

- 10

My pleasure, glad it was an easy fix. I was born and raised in Maine, moved away for 16 years, moved back almost four years ago, and some would still consider me "from away". Tough crowd.KVbeer, thank you again for sharing your PID settings. I never would have thought to go that low. After some “dry run” trial and error, I tried 35% (15 gallon Solo, 240 Volt). I hit all of my numbers with zero foam and no hops sticking to the side of the kettle. Win! I see you are living in Maine. I lived in Millinocket for a few years. I was “from away”. Thanks again for the tip. Cheers.

Oceangrace24

Well-Known Member

I have brewed 13 batches in my Solo with a Spike condenser lid. The learning curve was steep, but my process is now repeatable and under control. OG and FG are matching Brewsmith’s estimates exactly (that’s probably luck, not skill). I get a very pronounced trub cone in the whirlpool. My wort is clear with little or no grain. My mash doesn’t get stuck. My efficiency is equal to my old picnic cooler setup. Brewing indoors out of the wind and weather makes brew day a lot more pleasant. Cleanup is easy...not fun...but easy. All in all, this is a fantastic piece of equipment that works great. I am down to one remaining issue...or it may not really be an issue at all. I get a lot more foaming with the condenser lid than I used to with an open brew kettle. This causes a lot of hop matter to stick to the side of the brew kettle just above the wort level. Does anybody else have this problem? Is it even a problem? Is there a solution if it is a problem? My beer tastes better than ever so that might be the answer. Thanks, everybody, who posts on this forum. Your ideas, observations, and knowledge are a big help.

Add some Fermcap as you are getting up to boil temperature before the hot break starts. Or, wait and add it as your hot break starts to rise to see the effect that it has on the foam. It will basically eliminate it completely. I'll add about 10-15 drops. It's like $5 for a small bottle and I have had the same bottle for 2 years. I add it to my starters, to my boil and then to my fermenter. I also use it when I am cooking pasta! The stuff is magic.

Oceangrace24

Well-Known Member

I had my first brew Saturday on my 20G solo. I was hosting a brew session for my homebrew club, so there was 5-8 people always around me and the system while brewing, so It probably wasn't the most focused brew day. But that is ok, it was meant to be a learning day anyway.

I brewed an easy drinking Mexican Lager. Things went well for the most part. I had a few small issues that I am sure will improve with more batches and tweaking.

My observations, tweaks and results:

I brewed an easy drinking Mexican Lager. Things went well for the most part. I had a few small issues that I am sure will improve with more batches and tweaking.

My observations, tweaks and results:

- Efficiency ended up decent. According to brewfather, mash eff: 71%. Probably due to the amount of stirring I did.

- Draining was terrible. Took forever and I ended up 1 gallon short of my pre-boil target. I ended up boiling at a very, very gentle boil to try and not lose as much volume so I would have 11 gallons for the fermenter.

- I used a loc-line ring on my mash recirculation. This seemed to work well. I had to monitor the flow from the pump constantly to make sure it was draining fast enough. I hooked up a tube from the whirlpool port to use as a sight glass. This worked well and helped.

- I stirred the mash every 10 minutes at least or any time I noticed the level dropping. There was a fine line between having enough flow with the recirc to fill all of the outlets of the loc-line and the wort draining from the basket during the mash. But I finally got a happy point. I'll be adding mash enzymes next time.

- Mash temperature: One thing I noticed when setting everything up and reading this thread was the distance of the temp probe to the heating element. When I first put in my element in the kettle, I noticed that the Convex portion of the curve in the element was facing the temp probe. So I tuned the element over to make sure the probe was facing the concave portion of the element. I figured this would keep the element as far away from the probe as possible. Mash temps were pretty good. I am sure the fact that I was stirring the mash so often helped with this. I used a thermapen to measure the grain bed and it was about 2 deg off from the probe temp. This is about what I expected and was good with that.

- I measured my mash pH about 10 minutes in and almost freaked out. My recipe called for 10ml of lactic acid to get my mash to 5.2pH using brewfather. I took a sample 10 minutes coming out of the loc-line recirculation, cooled it down and it was in the 3.5 range. WHAT? So i stirred up the mash and took a sample off the top, chilled it and it was exactly 5.2. Not sure why the sample coming through the recirc was different, but I didn't worry at that point.

- I mentioned earlier in this thread that I already owned an IC and asked about putting the basket back in to rest the chiller on. This is what i did, but it came with issues. I will be hanging the chiller from the side in the future unless I get one of the devices from Jaded that lets your chiller rest above your element. The issue I had was when I put the basket back in with about 15 minutes left in the boil to sterilize it, the boil came up the sides of the kettle/basket and started coming out where the basket rests against the kettle. Pulled the basket and then just put it back down after the boil was over.

- I noticed grain in the boil while it was boiling and worried that I was going to have a bunch in the kettle at the end due to all the stirring. After the boil and doing a 10 minute whirpool, I really didn't notice much at all after draining. Element looked perfect after a quick rinse. I do about a 0.035 crush.

- I ended up with only 10Gallons in my fermenter once I racked it over. Was expecting/shooting for 11 gallons. I use a CF10, so I think the volume is measure before my added BF value, elbow and sight glass.

- I made a 4L starter and I typically make the starter, crash it, decant, and then pitch. Well, I didn't make the starter early enough and was only able to crash it for 24 hours. Most of the yeast dropped, but it wasn't as clear as I wanted. So with the idea that I was a bit short on my volume into the fermenter anyway, I went ahead and pitched the whole thing. This dropped my SG a few points, but not enough for me to worry this time.

- This was my first brew using pumps and valves and all that tubing. I love the quick disconnects. I only pulled a hose off an open valve once so that is a win, figured it would be more. Still learning that even with closed valves, there is still some liquid inside that will come out.

- Lifting the basket was no problem with 2 guys, but I will be getting a hoist for solo brewing. I'm Wondering if having the basket level while draining will help the drain rate instead of it being tilted and draining to one side.

user 295610

Active Member

- Joined

- Dec 28, 2020

- Messages

- 33

- Reaction score

- 10

I had the same concern, so I added a brace under the basket port to hold it level while lautering.Lifting the basket was no problem with 2 guys, but I will be getting a hoist for solo brewing. I'm Wondering if having the basket level while draining will help the drain rate instead of it being tilted and draining to one side.

Oceangrace24

Well-Known Member

Did that make any difference?I had the same concern, so I added a brace under the basket port to hold it level while lautering.

user 295610

Active Member

- Joined

- Dec 28, 2020

- Messages

- 33

- Reaction score

- 10

It certainly helps the wort drain through the grains evenly, so it looks like a better setup if nothing else. But in practice, I was also changing my grain crush and adding rice hulls in some batches so it's really hard to tell if it made any difference in my numbers. I also press the grains after lautering, and having the brace in place to keep the basket level I think helps get the last of the wort out, too.Did that make any difference?

- Joined

- Apr 7, 2021

- Messages

- 56

- Reaction score

- 48

OceanGrace24, thanks for replying.Add some Fermcap as you are getting up to boil temperature before the hot break starts. Or, wait and add it as your hot break starts to rise to see the effect that it has on the foam. It will basically eliminate it completely. I'll add about 10-15 drops. It's like $5 for a small bottle and I have had the same bottle for 2 years. I add it to my starters, to my boil and then to my fermenter. I also use it when I am cooking pasta! The stuff is magic.

Similar threads

- Replies

- 6

- Views

- 506

- Replies

- 2

- Views

- 495

- Replies

- 10

- Views

- 2K

- Replies

- 1

- Views

- 2K

Latest posts

-

-

-

For Sale Father's Passing: Homebrew Equip. Mega Sale

- Latest: leedspointbrew

-

-

-

-

-