Did you see the pictures? This is the glass you need Halfempty.Unless there are pics of said “brew shed” it doesn’t exist.Post them up so we can all see your brew space and drool.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your sculpture or brew rig

- Thread starter Onescalerguy

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

user 225792

Twisted Mustache Brewing

- Joined

- Jun 30, 2016

- Messages

- 16

- Reaction score

- 4

Brew tree I designed and built in 2007. Had the stand professionally welded since I am horrible at that skill. We call it the "Tower of Power. Each vessel has a 55,000 BTU burner (propane).

Built this out of a fragrance stand that was being scrapped and a stainless countertop I found at my grandparents. Works great! I had to cut the stand down and re weld some of the box steel up for the gravity fed HLT.

It’s still a work in progress, I need to figure out a way to hang some hooks to put the lids.

It’s still a work in progress, I need to figure out a way to hang some hooks to put the lids.

Attachments

Hotrod from Brewhardware. I have one in my system. Nice!Here’s my RIMS system with electric HLT.

Couldn't open it. With a name like Tower of Power the pic was blocked because it either resembles a part of the male Anatomy, Frank Zappa complained, or John Blickmann has the patent for his tower of power. Hmmmm?

Brew tree I designed and built in 2007. Had the stand professionally welded since I am horrible at that skill. We call it the "Tower of Power. Each vessel has a 55,000 BTU burner (propane).

Isn't your oxygen tank a bit close to the burner, or is it just there to have it in the pic? Very nice setup though.

Brewbuzzard: Thanks for your reply and comment. Yes in that shot the tank is too close to run the burner under our hlt safely, but it’s now been converted to an electric here’s kettle, controlled by a PID in the panel, so we very rarely use the hlt burner these days. The o2 tank lives against the wall to the left, and is only moved into place for knocking out. We plan to give it a longer hose and quick disconnect in the future. Right now it’s connected with a hose barb and clamp. There is always room for improvement!!

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

user 225792

Twisted Mustache Brewing

- Joined

- Jun 30, 2016

- Messages

- 16

- Reaction score

- 4

Let's try this again. First post didn't show the photo....

Brew tree I designed and built in 2007. Had the stand professionally welded since I am horrible at that skill. We call it the "Tower of Power. Each vessel has a 55,000 BTU burner (propane).

Brew tree I designed and built in 2007. Had the stand professionally welded since I am horrible at that skill. We call it the "Tower of Power. Each vessel has a 55,000 BTU burner (propane).

hafmpty

Well-Known Member

Let's try this again. First post didn't show the photo....

Brew tree I designed and built in 2007. Had the stand professionally welded since I am horrible at that skill. We call it the "Tower of Power. Each vessel has a 55,000 BTU burner (propane).

View attachment 573086

You’re good. It’s showing up now. Nice setup.

Now I see it, looks nice.Let's try this again. First post didn't show the photo....

Brew tree I designed and built in 2007. Had the stand professionally welded since I am horrible at that skill. We call it the "Tower of Power. Each vessel has a 55,000 BTU burner (propane).

View attachment 573086

Here is my HERMS system. Thinking about going electric once I get my new garage built.

Here’s a system I cobbled together to hold me over until I get my electric brewery installed and running. Been slow returning to brewing since my move from south Jersey to Florida.

Attachments

Komodo

Well-Known Member

AMAZING! What a thing of wonder and joy.

First post in a couple years just because I saw this (I've been brewing the whole time).

Just about to add new video about the smoker and grill stuff.. most likely tomorrow! Hope you enjoy!I watched your video, love the simplicity of the mash stirrer! And really curious about your BBQ, smoker stuff...you should join us over here

https://www.homebrewtalk.com/forum/index.php?threads/637254/

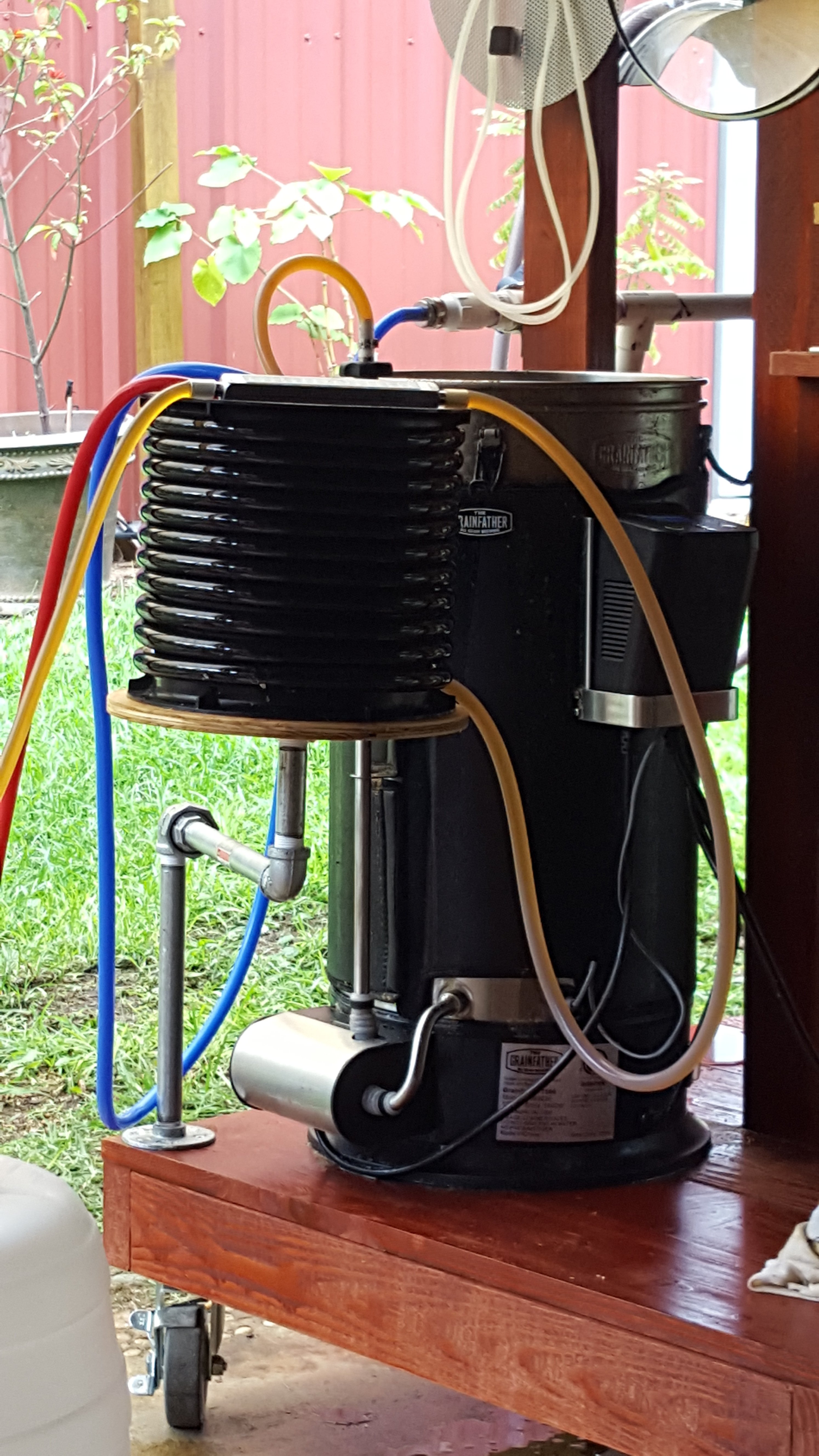

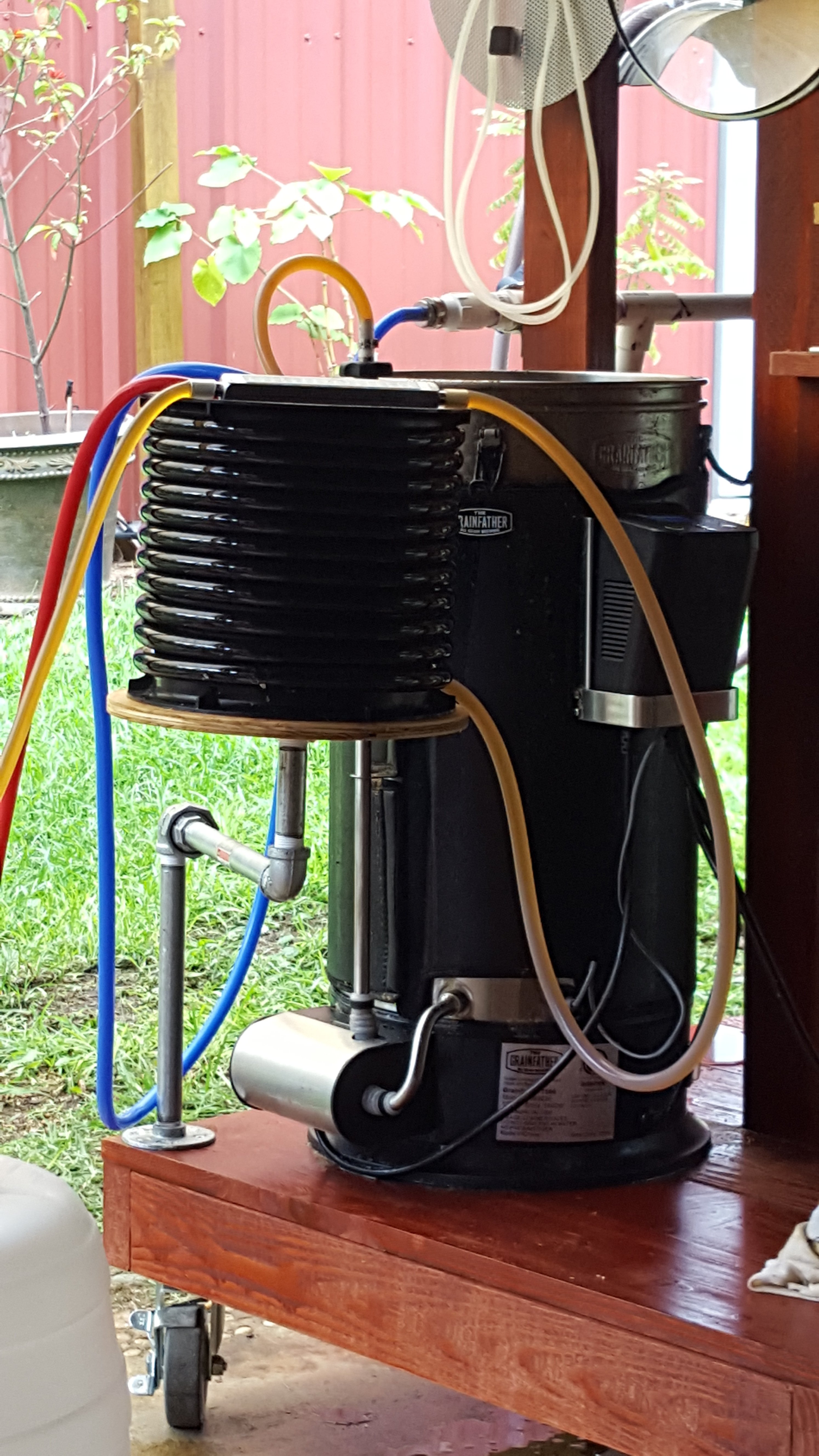

I may as well hop on the bandwagon here. I used some of the ideas posted here for my Grainfather brew stand which some of you will recognize. I implemented something that I haven't seen before and that is a swing-out table for the chiller. Thanks goes to Fred Flintstone for the pipe design. Special thanks goes out to the "Our Gang" kids school of carpentry.

Debuting yesterday, I have a double wide brew stand on wheels. With a work bench, storage space and my water iron filters mounted to the side. The extra elevation given from the wheels makes it easier on my back when stooping over the Grainfather.

Debuting yesterday, I have a double wide brew stand on wheels. With a work bench, storage space and my water iron filters mounted to the side. The extra elevation given from the wheels makes it easier on my back when stooping over the Grainfather.

Attachments

Last edited:

Looks very nice. I have a sink something like yours.Here’s a system I cobbled together to hold me over until I get my electric brewery installed and running. Been slow returning to brewing since my move from south Jersey to Florida.

That is beautiful! Does it do time travel as well?

AMAZING! What a thing of wonder and joy.

First post in a couple years just because I saw this (I've been brewing the whole time).

Well thanks! I am happy you liked my little project

I am just working on a youtube channel and have added few videos there. Just today I added new video about the grill and smoker I buit to my cabin. go and take a look if you are interested:

https://www.youtube.com/channel/UCKxDop_iEM_OGU0gXwY7Q2w?

You need to ask?That is beautiful! Does it do time travel as well?

I've seen similar yellow flex hoses used with bg14s, so I'm going to say "yes".

Cheers!

Cheers!

I used the same size on my old gas rig and had no supply problem. The point that did give me issues was the valve I used. I used a regular gas ball valve which did not have as smooth an operation as a needle valve. The ball valve dumps too much gas all at once and can blow out the pilot light and remove your eyebrows.Will these 1/4" ID 2 foot lenth hoses fit the bill, or will it be too small to run a BG14?

Back says rated for 40k BTU. They were on clearance for $5 at Home Depot, so I shot first and am asking second.

Attachments

Carlscan26

Well-Known Member

I used the same size on my old gas rig and had no supply problem. The point that did give me issues was the valve I used. I used a regular gas ball valve which did not have as smooth an operation as a needle valve. The ball valve dumps too much gas all at once and can blow out the pilot light and remove your eyebrows.

Brewbuzzard, what did you use to control the solenoid?

Just a manual switch. The pilot light was before the solenoid. It could just as well have been a PID and relay. I was planning to add an electric control panel but decided to go all electric and built a building to put it in so I did away with propane. Now I need to sale the gas rigBrewbuzzard, what did you use to control the solenoid?

Last edited:

Loving the mail boxes - as long as the backs were cut out.

You can easily cook a Chugger motor to thermal shutdown with inadequate ventilation...

Cheers!

You can easily cook a Chugger motor to thermal shutdown with inadequate ventilation...

Cheers!

budaboff

Well-Known Member

- Joined

- Feb 2, 2013

- Messages

- 51

- Reaction score

- 8

Loving the mail boxes - as long as the backs were cut out.

You can easily cook a Chugger motor to thermal shutdown with inadequate ventilation...

Cheers!

The backs are gone...and now so is the bottom. Maybe a stronger box would support it better but after a run through, I wasn’t happy with the support. The pumps are now mounted to the frame with the arches installed as covers. I probably would fare better with just rolling steel, but these were cheap enough to cut apart.

Other issues I’m running into:

1. Back flow into pots when I stop the pump

2. Best way to clear the lines after shutting off the pump

Not sure what you mean by back flow when the pump stops. If needed, I'll close a valve somewhere.The backs are gone...and now so is the bottom. Maybe a stronger box would support it better but after a run through, I wasn’t happy with the support. The pumps are now mounted to the frame with the arches installed as covers. I probably would fare better with just rolling steel, but these were cheap enough to cut apart.

Other issues I’m running into:

1. Back flow into pots when I stop the pump

2. Best way to clear the lines after shutting off the pump

As far as wort in lines, I chalk that up as lost liquid unless I can salvage some of it with out spilling it all.

budaboff

Well-Known Member

- Joined

- Feb 2, 2013

- Messages

- 51

- Reaction score

- 8

Not sure what you mean by back flow when the pump stops. If needed, I'll close a valve somewhere.

As far as wort in lines, I chalk that up as lost liquid unless I can salvage some of it with out spilling it all.

When I stop the pump, the liquid start flowing back up into my mash tun. I just need to remember to close valve first, I just wasn’t expecting that to happen.

ancientmariner52

Well-Known Member

When you stop pumping, the liquid will flow until the pressure due to gravity is equalized. If you've been pumping uphill, then yes, backflow happens. Get in the habit of shutting the discharge valve then immediately stopping the pump.When I stop the pump, the liquid start flowing back up into my mash tun. I just need to remember to close valve first, I just wasn’t expecting that to happen.

To clear wort from the pump and lines, I add clean water to the kettle and use it to push the remaining wort out of the system. You need to be able to see the discharge to be able to tell when the color changes. Even with my small rig, this saves a couple bottles of beer.

Similar threads

- Replies

- 11

- Views

- 1K

- Replies

- 132

- Views

- 8K

- Replies

- 45

- Views

- 4K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)