Thank you! that what happens when you put a crazy artist on a projectThat is one of the more remarkable combinations of art and function I have seen in a while - very nicely done!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your sculpture or brew rig

- Thread starter Onescalerguy

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

easy to see I like steampunk style?That is a thing of steampunk beauty!

- Joined

- Jun 12, 2014

- Messages

- 574

- Reaction score

- 191

Brew stand. 2.0 : in the process of a rebuild.

View attachment 569309View attachment 569312

Propane/rims to electric/herms

what did you use to insulate your mash tun?

TANSTAAFB

Well-Known Member

I watched your video, love the simplicity of the mash stirrer! And really curious about your BBQ, smoker stuff...you should join us over hereeasy to see I like steampunk style?It was interesting project to create all those parts. The control panels I draw with Inkscape and then used laser cutter. They are actually made of mdf that I just painted copper & some stains

https://www.homebrewtalk.com/forum/index.php?threads/637254/

Desert_Sky

Since 1998

My third rig. This one is a Brutus style 11 Gallon post boil rig. I fully plan on replacing the plastic cooler, just havent decided on a bottom drain MT yet.

As of now all manual with dual pumps and camlock QDs. Obviously I cant commit to a brand either

Last edited:

Pure gravity system, it's been modified a bit since this picture but I haven't taken another one yet. So far it's working well.

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

HootervilleHops

Well-Known Member

Adhesive backed PVN - polyvinyl nitratewhat did you use to insulate your mash tun?

don't ask me about it shmbo is a foam materials engineer. :0

- Joined

- Jul 6, 2013

- Messages

- 142

- Reaction score

- 56

@pinchegil

Can you tell us about the gas line connectors or post a link? I'm particularly curious about the burner end.

pinchegil

Strangedog Brewing

The are Tejas Smokers CVO250 . they are for high pressure propane I have two for my mash and boil kettle, my mlt is controlled using a honeywell so I have a two stage regulator to drop 35lbs to 11 inches of water because of this I called them and they opened the orifice for me. These are all connected to Bayou Classic BG14s. They are a really nice feature@pinchegil

Can you tell us about the gas line connectors or post a link? I'm particularly curious about the burner end.

https://tejassmokers.com/Brass-Fittings-Valves/22#brass9

They replace your orifices

Last edited:

steveoatley

someone has to fail, so the rest of you look good

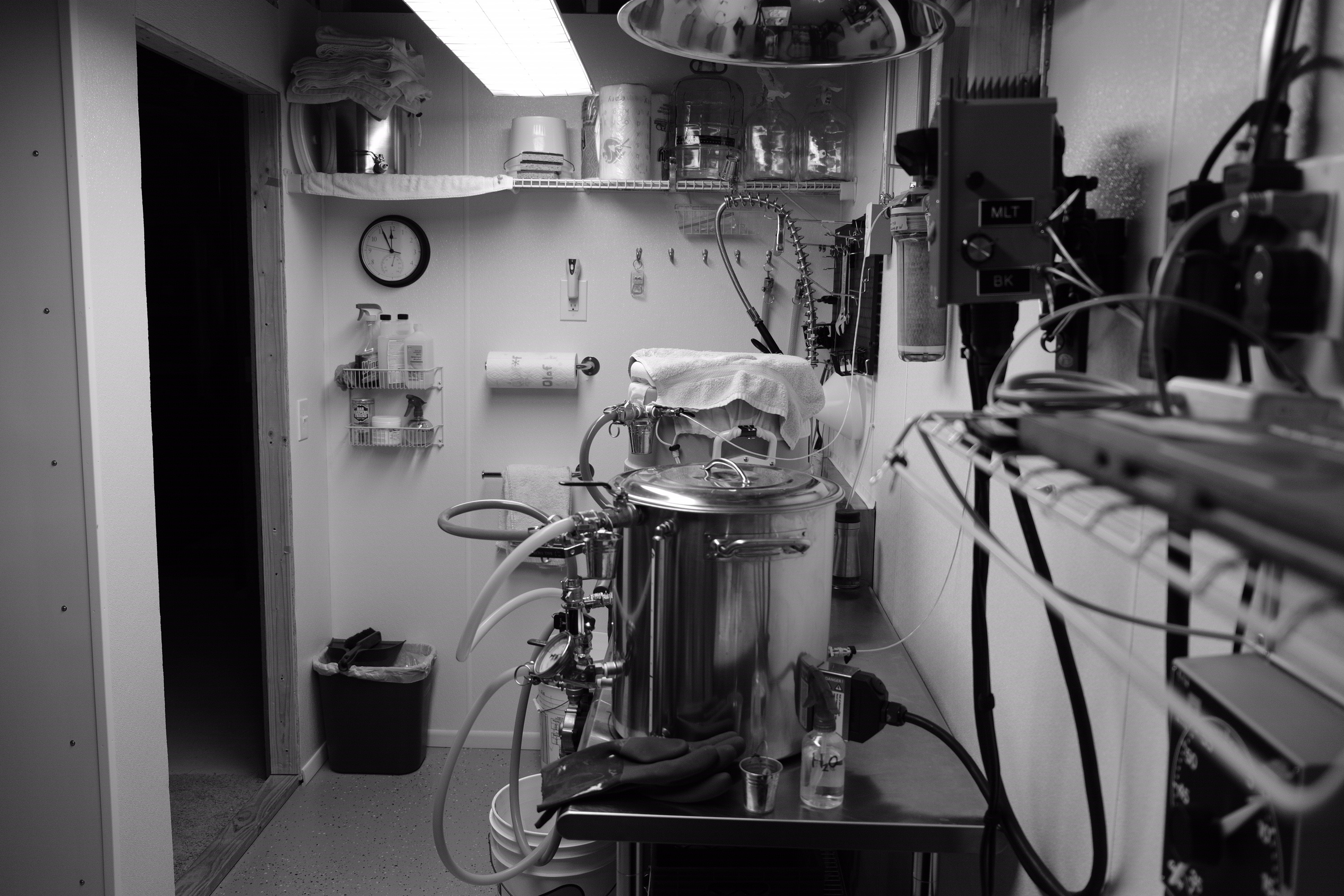

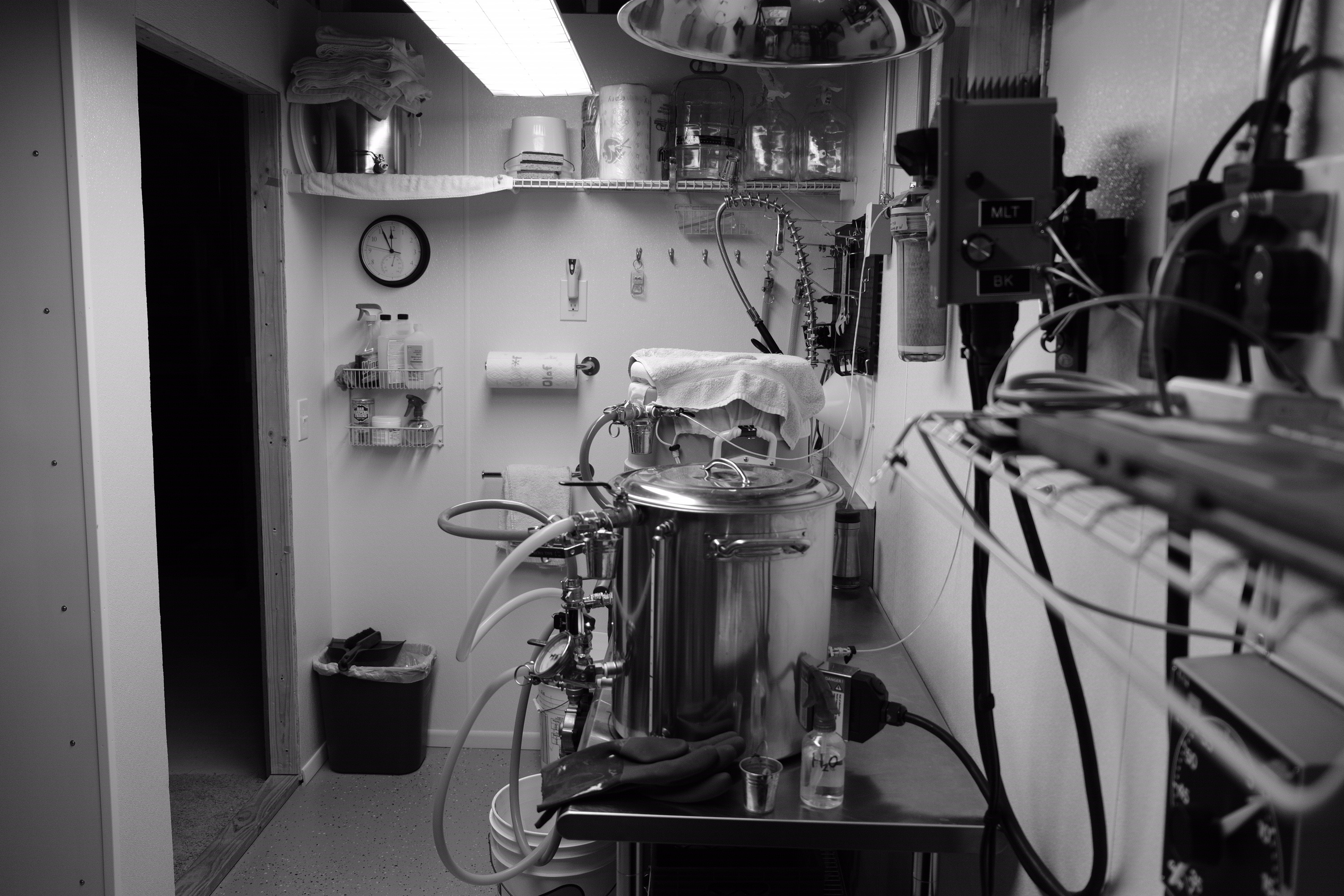

This thread inspired me... way back in the "old days"

to move to electric, and move indoors.

Here is my Electric Basement Brewery

Thanks to everyone at HBT for the inspiration !

And all the technical help

to move to electric, and move indoors.

Here is my Electric Basement Brewery

Thanks to everyone at HBT for the inspiration !

And all the technical help

- Joined

- Jul 6, 2013

- Messages

- 142

- Reaction score

- 56

Thanks for the link. I use the BG14s as well. Q: on a normal propane tank am I at low pressure?

"Low Pressure" is 11" WC which is roughly .4 psi - most propane gas grills run that low. But the typical brew burner will come with a 10 psi or greater regulator, so the answer is most likely No...Thanks for the link. I use the BG14s as well. Q: on a normal propane tank am I at low pressure?

Cheers!

pinchegil

Strangedog Brewing

the BG14s come with a high pressure orifice which is what you use for a normal propane regulator and tank so you are good to go!! You would only run low pressure if you were connecting it to NG from your house, or if you were adding automation using a furnace valve. In which case you would need to ream out the orifices."Low Pressure" is 11" WC which is roughly .4 psi - most propane gas grills run that low. But the typical brew burner will come with a 10 psi or greater regulator, so the answer is most likely No...

Cheers!

Throttle79

Cache Creek Brewing

10 gallon 50amp all-electric RIMS

- Joined

- Jul 6, 2013

- Messages

- 142

- Reaction score

- 56

Love the Springsteen reference! More like Brewwww-ceThis has taken a bit. But here it is. I am calling it Brew-ce. <snip>

Carlscan26

Well-Known Member

The are Tejas Smokers CVO250 . they are for high pressure propane I have two for my mash and boil kettle, my mlt is controlled using a honeywell so I have a two stage regulator to drop 35lbs to 11 inches of water because of this I called them and they opened the orifice for me. These are all connected to Bayou Classic BG14s. They are a really nice feature

https://tejassmokers.com/Brass-Fittings-Valves/22#brass9

They replace your orifices

How many turns do you have from full closed to full open? Do they fall back a little when you adjust them or do they stay exactly where you put them(if that makes sense)?

Electric BIAB. 10 gallon kettle to make 5 gallon batches.

pinchegil

Strangedog Brewing

I would have to check, when setting up I shut them, the I turned the regulator full up, then I cracked the needle valve till i could light burner, then I turned an eighth, then messed with the air, then did this again till I found the sweet spot. Since then, I just nudge them either way when i turn it on. Not sure you would have to do this at sea level but at 6400 feet and the type of day you will always have a little nudging. They will stay exactly in place if you do not touch themHow many turns do you have from full closed to full open? Do they fall back a little when you adjust them or do they stay exactly where you put them(if that makes sense)?

cyberbackpacker

Well-Known Member

- Joined

- Jul 12, 2017

- Messages

- 489

- Reaction score

- 422

There are a lot of photos scattered over many threads of brewing set-ups.I looked all over the web for pics and ideas for a simple sculpture.Maybe it'll help someone to see a bunch in one place.

This was a fairly simple project.

Cheers

- Joined

- Jun 12, 2014

- Messages

- 574

- Reaction score

- 191

View attachment 570418 This has evolved over the last couple of years. It runs like a champ now.

View attachment 570418

holy huge a$$ counterflow chiller batman!

is the smaller coil in the pot under the stand a HERMS/temp control thing? I notice you have a temp probe directly on the output side of it going back into the mashtun (I assume it's a mashtun).. how do you modulate the temperature in that? (is there a coil/heat stick in there I can't see?)

how much heat-loss do you get from recirculating through all that copper?

It’s actual brewers and vintners hose, only half inch id. Probably should have gone 3/4, but the flow rate is way more than adequate with our little giant pumps. I recall it being really difficult to get onto the barbed fittings. It was $7 per foot from McMaster. Here’s the link: https://www.mcmaster.com/#catalog/53715K41

It’s really durable stuff, never kinks, and our 3 original hoses are approaching 10y old and still going strong!

We used that fittings from Pro flow dynamics. No regrets other than ordering from pro flow twice, over a year apart. They switched suppliers so the fittings from the second order are compatible but slightly different. It bothers me a tiny bit but no leaks though!

- Joined

- Jul 12, 2017

- Messages

- 489

- Reaction score

- 422

The smaller coil is my original herms coil set up from back when I had 2-10 gallon coolers( mash tun , hot liquor tank) . There is a 4500 watt element in that 5 gallon pot and the controller on the left controlled that. The heat loss is about 10 degrees from one end to the other if you were not reheating it back up at the herms coil. I still use it as I like only heating 5 gallons of water to control temp, and my 20 gallon HLT is heating sparge water independently. HLT and BK both have 5500 watt ripple elements. The counter flow chiller takes you from boiling to whatever temp you incoming water is in one pass with Chugger pumps running full blast, in winter I have to slow the flow of incoming water or you will end up with wort in the high 40's or low 50's.holy huge a$$ counterflow chiller batman!

is the smaller coil in the pot under the stand a HERMS/temp control thing? I notice you have a temp probe directly on the output side of it going back into the mashtun (I assume it's a mashtun).. how do you modulate the temperature in that? (is there a coil/heat stick in there I can't see?)

how much heat-loss do you get from recirculating through all that copper?

Last edited:

[[...]I customized the Autosparge in the hopes of avoiding channeling during the recirculation. [...]

Neat looking system.

fwiw, I've been using the same Blichmann autosparge valve for a couple of years in a 20g mlt and ime if you use the product the way it was designed there will be no channeling, and no need for all that copper in your mash...

Cheers!

Similar threads

- Replies

- 11

- Views

- 1K

- Replies

- 130

- Views

- 7K

- Replies

- 45

- Views

- 4K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)