pricelessbrewing

Brewer's Friend Software Manager

He's moving his website, they should be back next week I think he said with the stainless elements.

Hot Rod Ordered and on the way. This will be my Heat Stick supplementing my indoor AG brews until my EBIAB build gets done this spring.

Nice I want to order one for the same thing but It doesn't look like bobby offers a 1500w stainless steel element and the 2000w is to big for my kitchen. I'm wondering if I got one off eBay if it would be the same fit in the hot rod?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

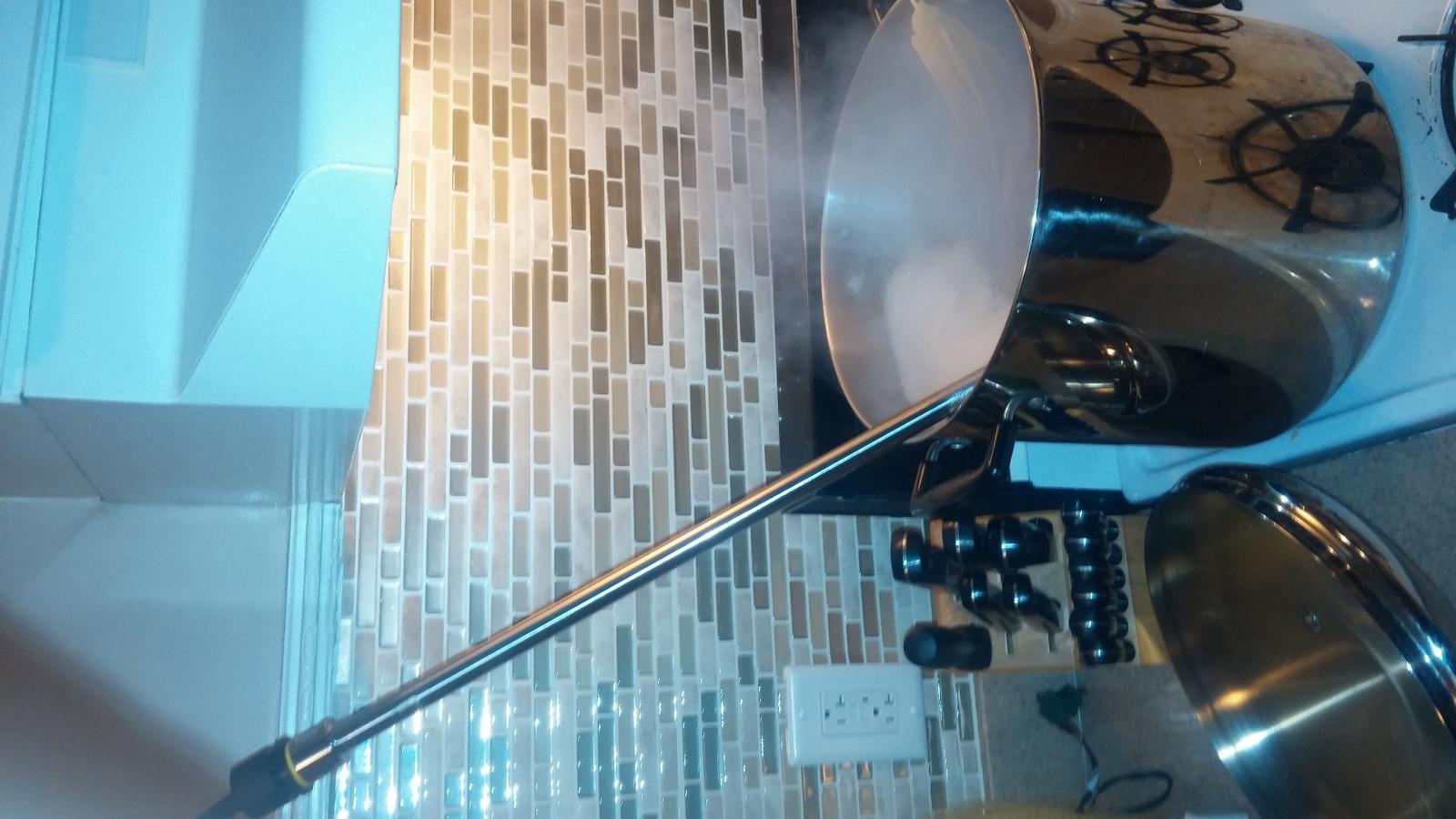

Sorry, that was not the picture that I intended to post. But it does show my alternative to having the bend in the tube.

Thanks Bobby for another great product.

Good notes. The two fender washer trick will work for pots that don't have any kind of rolled top lip, but I need to figure out a less invasive solution for a wider variety of pots. Honestly, this is really the reason the price is as low as it is. I'm selling the first 50 at near break even pricing because although the business end of the unit is fully up to my expectation, it's not a mature product in my mind without a universal mount.

On the crimp terminals... it definitely helps if you put a bit of a bend in the ring terminals for the element connection so that the wires are not jutting out directly to the side walls of the housing. I think I bent a 45 degree in them with a pair of needlenose pliers. Shrink the heatshrink on after bending.

Ok bbohanon I went with the 2000w element on your advice just placed my order looks like a great product way better than I was going to build