I recently finalized my months-long decision on a brewing system and decided that I'd go 3 vessel RIMS or HERMS and made my first hot side purchases: The SS Brew Kettle BME and the Infussion Mash Tun, both in 10 G. I'll figure out the third vessel and which direction I go with heating the mash at a later date, but compared to my makeshift 6 gallon BIAB set-up, this is a huge step up for me.

What I recieved was not up to my expectations, and to be fair to SSBT, They were quick to respond to my issues and offer some solutions. Also, big props to OBK here in Canada as they immediately offered me my choice of a return or exchange at no cost to me. I'm posting this for a few reasons.

1) I want to gauge what others are experiencing from SSBT as I was planning on purchasing more from them in future. I am now obviously second guessing that. Once I receive my exchanges, I'll have a better idea on that.

2) I want to make sure that others in the community are aware of what I recieved. I believe you should have access to all the information (good and bad) before making a purchase. Stuff happens, and it's important to know what level of support you'll receive when that stuff happens.

3) I want to hear from the community if I'm making too big a deal out of this stuff. For example, is rust on welds inside a kettle a major concern, or an easy fix?

Here are the issues:

Infussion Mash Tun

Issue # 1 - Bottom Plate Screw

As you can see above, one of the four screws that holds the bottom plate on had its threads totally sheared off during installation. I found this screw on the bottom of the box after I noticed the bottom plate hanging down a bit.

Issue # 2 - Warped Base

This segways nicely into issue #2 (you can also see how loose the bottom plate is due to that missing screw from Issue #1). The base of the unit is heavily warped, especially in the top left corner in the photo above. This warping causes the feet to be out of level, and the whole unit rocks unsteadily. I doubt this is a safety concern given how short the legs are, but it certainly is annoying.

SSBT suggested the MT was dropped in shipping. I think that's fair enough, though I question why this is only spot welded. We will see on the second go around if this issue persists.

SS Brew Kettle BME

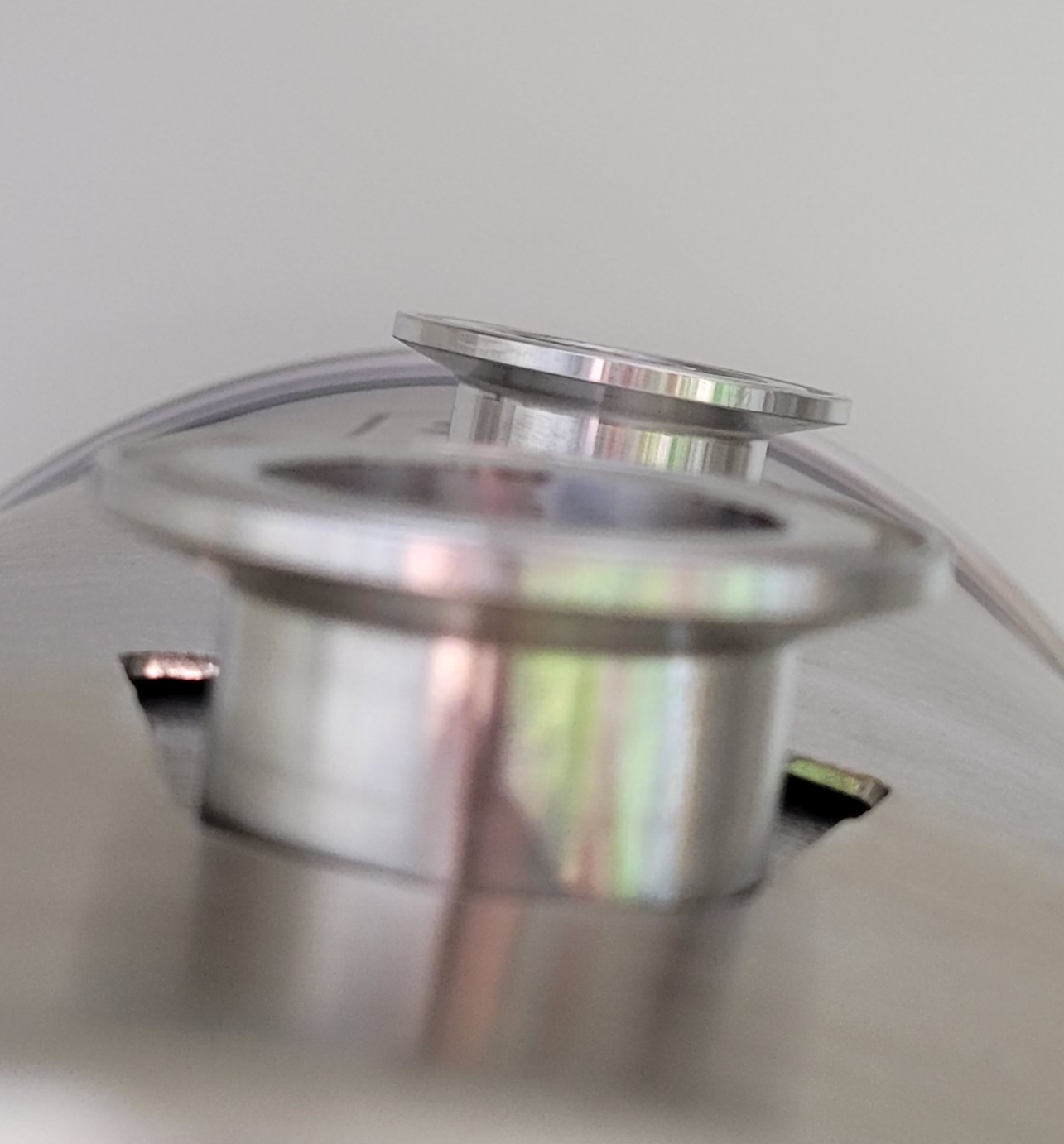

Issue # 3 - Rust on the Outport

This issue is the one that concerns me the most, as it will be touching the beer and will only get worse with time. The welds on the main port on the brew kettle are rusting. I followed the instructions and cleaned both of these units with TSP, and followed that with a soak in Star San, both mixed to the manufacturers recommendations. I scrubbed a lot of rust off this port, but without using something abrasive the photos above are the best I could do. The entire time, I couldn't help but think "why am I having to do this on a premium product?"

This issue is the one that concerns me the most, as it will be touching the beer and will only get worse with time. The welds on the main port on the brew kettle are rusting. I followed the instructions and cleaned both of these units with TSP, and followed that with a soak in Star San, both mixed to the manufacturers recommendations. I scrubbed a lot of rust off this port, but without using something abrasive the photos above are the best I could do. The entire time, I couldn't help but think "why am I having to do this on a premium product?"

SSBT recommend using bkf to get this off. I want to know if that will solve this issue once and for all assuming that I acidulate afterwards, or if this is a more serious flaw.

Issue # 4 - Alignment

The final two issues with these products involve the alignment of the ports on and the levelness of the SS Brewtech logo. Starting with the ports, I left the ball valve on to demonstrate how out of alignment it is with the thermometer well. Secondly, the logo on the front of the kettle is off by about 1.5 degrees. It's enough you can tell just by looking at it. Though not an egregious issue, considering everything else that is wrong with these two units, it really does help paint a picture of poor manufacturing quality control.

The final two issues with these products involve the alignment of the ports on and the levelness of the SS Brewtech logo. Starting with the ports, I left the ball valve on to demonstrate how out of alignment it is with the thermometer well. Secondly, the logo on the front of the kettle is off by about 1.5 degrees. It's enough you can tell just by looking at it. Though not an egregious issue, considering everything else that is wrong with these two units, it really does help paint a picture of poor manufacturing quality control.

Very curious to hear your thoughts and experiences with SSBT! Thanks you for reading.

What I recieved was not up to my expectations, and to be fair to SSBT, They were quick to respond to my issues and offer some solutions. Also, big props to OBK here in Canada as they immediately offered me my choice of a return or exchange at no cost to me. I'm posting this for a few reasons.

1) I want to gauge what others are experiencing from SSBT as I was planning on purchasing more from them in future. I am now obviously second guessing that. Once I receive my exchanges, I'll have a better idea on that.

2) I want to make sure that others in the community are aware of what I recieved. I believe you should have access to all the information (good and bad) before making a purchase. Stuff happens, and it's important to know what level of support you'll receive when that stuff happens.

3) I want to hear from the community if I'm making too big a deal out of this stuff. For example, is rust on welds inside a kettle a major concern, or an easy fix?

Here are the issues:

Infussion Mash Tun

Issue # 1 - Bottom Plate Screw

As you can see above, one of the four screws that holds the bottom plate on had its threads totally sheared off during installation. I found this screw on the bottom of the box after I noticed the bottom plate hanging down a bit.

Issue # 2 - Warped Base

This segways nicely into issue #2 (you can also see how loose the bottom plate is due to that missing screw from Issue #1). The base of the unit is heavily warped, especially in the top left corner in the photo above. This warping causes the feet to be out of level, and the whole unit rocks unsteadily. I doubt this is a safety concern given how short the legs are, but it certainly is annoying.

SSBT suggested the MT was dropped in shipping. I think that's fair enough, though I question why this is only spot welded. We will see on the second go around if this issue persists.

SS Brew Kettle BME

Issue # 3 - Rust on the Outport

SSBT recommend using bkf to get this off. I want to know if that will solve this issue once and for all assuming that I acidulate afterwards, or if this is a more serious flaw.

Issue # 4 - Alignment

Very curious to hear your thoughts and experiences with SSBT! Thanks you for reading.