First, let me say is good to be back and have the time to write again. I missed it, but I have more time for the hobby and/so have more time to share.

I love projects, and I have been racking my brain for years watching and wondering about e-brewing. Now almost everywhere I look, it seems to me people have turned to electric mashing/brewing/biab-ish combo-type setups for convenience and control. Well, I have evolved! I will still do single infusion brews on my new setup, but now I will have the ability of "hopefully" 100% controlling step infusion mashes. (I haven't bet it all on that horse, as there are many variables for external wort heating devices. Mine I would think is no different, but now...I get to have fun experimenting and trying it out numerous ways to see how capable it is.) However, the intention of this build is to control finer tuned temperature ramps with near boiling water infusions. I'm 99% confident it can handle this task. There are multiple reasons I want to brew step infusions now, but I couldn't see the point doing the whole ramp with a 120vac element in a rims tube, or recirculating through a herms tube. Reading about them only mind you, they all took too long IMHO and so, for my brewery I chose manually adding boiling additions and focused on "over-doing" control. I'll layout some pics and hopefully explain how my hybrid setup works.

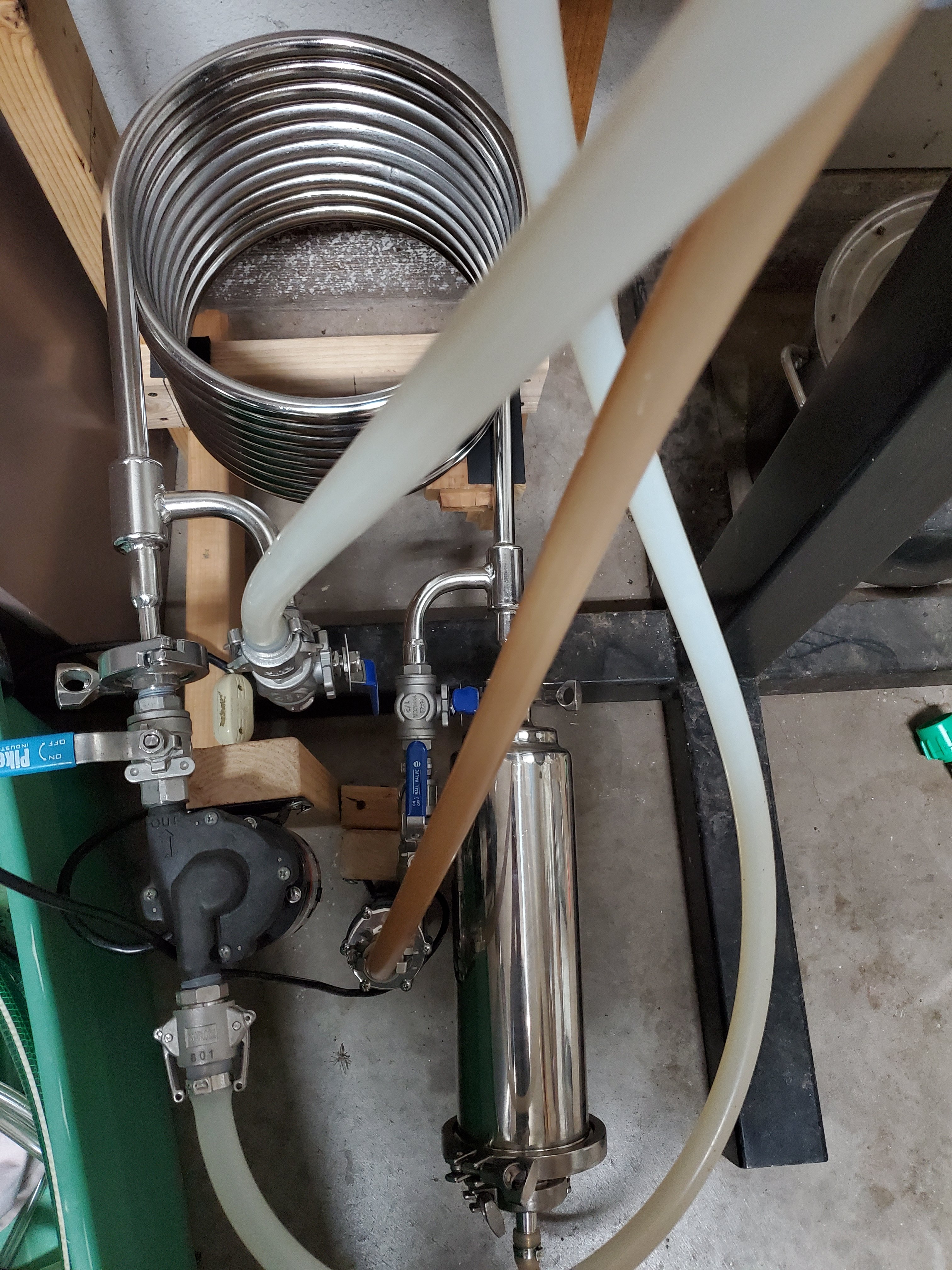

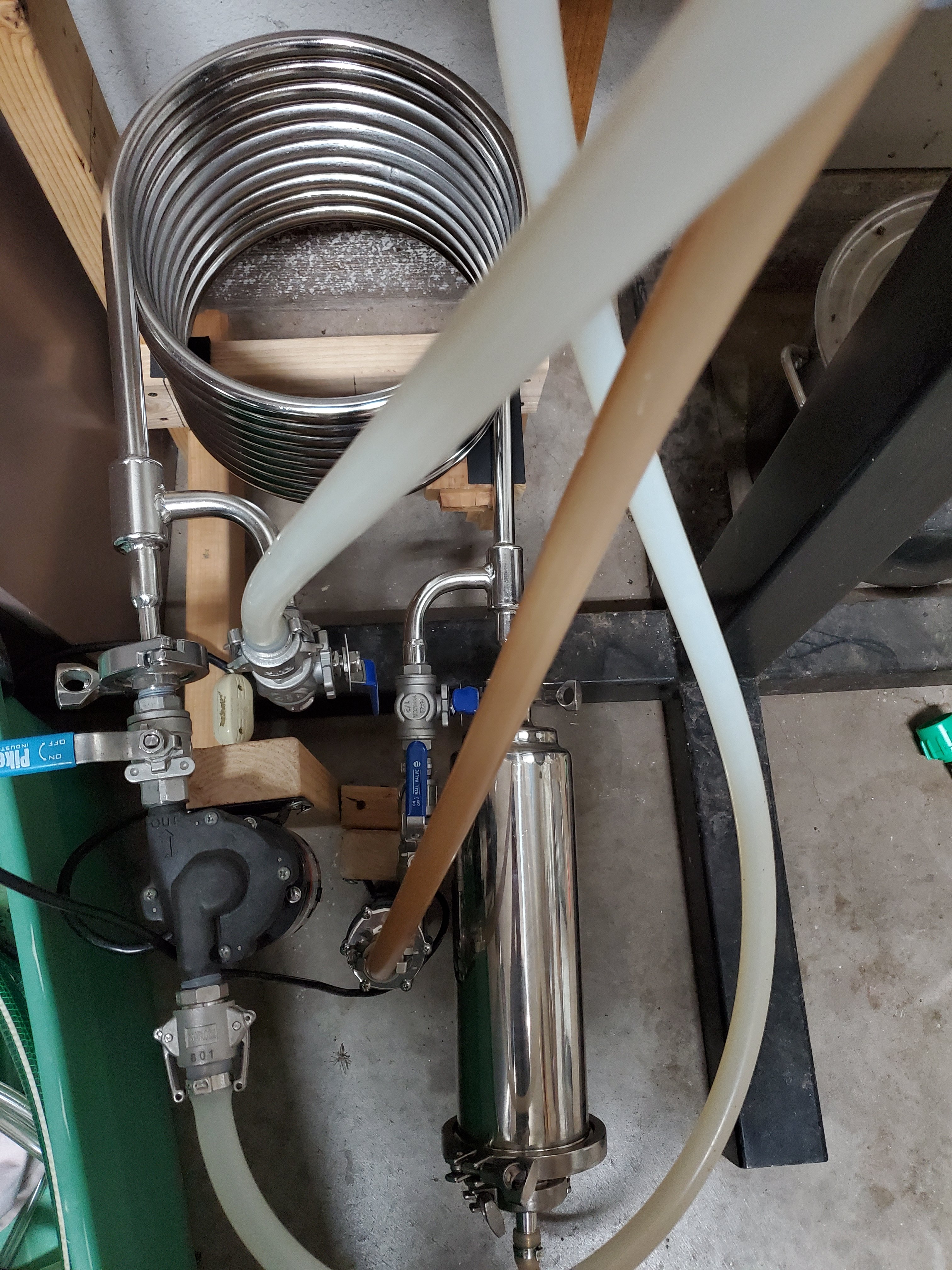

The upper vessel is my old HLT. It is controlled by Ranco controller attached to the vessel, it's an old custom job I did years ago (notice the pipework going through it, lol I used to think stuff like that was cool... but what happens when the Ranco breaks you supercool idiot????) From HLT drain, water goes into the "Super-Badassed-THANK YOU-Bobby_M-RIMS tube" pulling almost it's max current @120vac if it needs to. Essentially boosting incoming water temperature "if needed" on its way to the HERMS coil, before returning to the HLT. The RIMS tube element is controlled by the PID in the black box on the left of the 2nd vessel down (Mash Tun). More on the box in a minute. The temperature sensor (I chose a PT100) for the box PID is located at the top of the MT, on the left side of the converted three-way ball valve so it "receives" what the mash is receiving. That is the whole RIMS-HERMS control I was after with a ZERO% chance of scorching...EVER! Overkill... yes! It will do as it is told, and it will put the lotion on the skin when told to, so I don't care what it cost to relieve any variables. The three-way valves on the HERMS coil change it into my counterflow wort chiller when the time comes, so I get double duty out of it.

As for the wort side, that's easy to explain. Bottom of MT to wort pump (furthest left in picture), then through the coils from top to bottom (anti RIMS-HERMS water direction) before being filtered inline with a wort strainer on its way to the temperate sensor and MT. The strainer is bypassed initially to allow for debris to return to the MT before a filter bed is set. Nothing special, just custom for what I want to do.

After knock out from the MT and transfer, there is going to be a ton of stuff left in the lines.

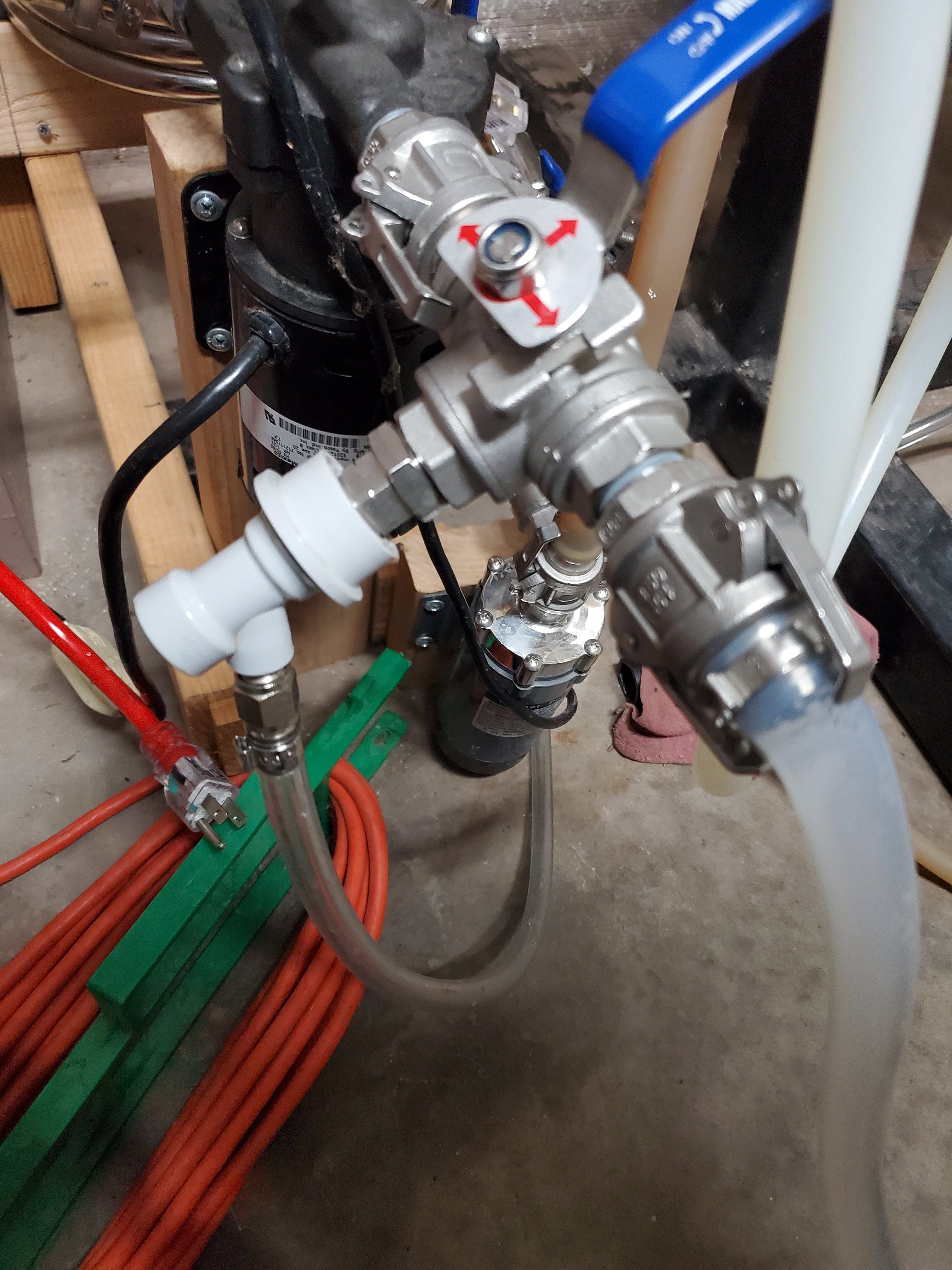

That's where this little guy comes in. I'm going to hook CO2 up to my brewery to push lines clear, or unstick a stuck sparge, at low pressure of course. When I'm in the kettle, I'll clean the wort lines and get everything ready for whirlpool and chilling. Here's where the OVER-SIZED wort strainer comes in. I'm hopeful it will take 100% of the kettle hop bill during whirlpool, as well as break material. It's 4" and girthy, we will see. This CO2 valve with ball lock fitting will allow me to push almost 100% of my product to the fermenter. With this valve I will also have the ability to flood my MT with CO2 for low oxygen experimenting. I want to try lots of things!

Here some up close pics of the control box. It is wired with input from two separate legs of power from the breaker for each circuit. Circuit 1 powers lower red receptacle for RIMS element. It will not come on unless Circuit 2 RIMS pump is on, the key is turned, and the RIMS element button is on. Safety third! The volt meter comes on with RIMS element to tell me what it is pulling as a reference. Everything else on the box is powered by Circuit 2. Buttons are top left Wort Pump, bottom left RIMS Pump, bottom right RIMS Element, top right HLT Ranco ETC.

Here's a top and side view of the heat exchanger and pumps.

I attached this to the top of the RIMS tube to allow air to escape.

I have thought about this for a very long time, of how I wanted some things changed (in my brewing setup) for ease or just ease of mind. Hope you guys enjoy! I can't wait to try it out very soon. Questions, comments, I take them all. I would like to thank Bobby_M at brewhardware.com for the purchasing of my gadgetry, but mainly for the SS tubing bent w/fittings welded on. Very good price on such custom things is rare, and he ships fast!

I think I have one more project in me, my chest freezer fermentation chamber compressor broke, so I bought a window unit for it and love it better. Write up and pics COMING SOON!

I love projects, and I have been racking my brain for years watching and wondering about e-brewing. Now almost everywhere I look, it seems to me people have turned to electric mashing/brewing/biab-ish combo-type setups for convenience and control. Well, I have evolved! I will still do single infusion brews on my new setup, but now I will have the ability of "hopefully" 100% controlling step infusion mashes. (I haven't bet it all on that horse, as there are many variables for external wort heating devices. Mine I would think is no different, but now...I get to have fun experimenting and trying it out numerous ways to see how capable it is.) However, the intention of this build is to control finer tuned temperature ramps with near boiling water infusions. I'm 99% confident it can handle this task. There are multiple reasons I want to brew step infusions now, but I couldn't see the point doing the whole ramp with a 120vac element in a rims tube, or recirculating through a herms tube. Reading about them only mind you, they all took too long IMHO and so, for my brewery I chose manually adding boiling additions and focused on "over-doing" control. I'll layout some pics and hopefully explain how my hybrid setup works.

The upper vessel is my old HLT. It is controlled by Ranco controller attached to the vessel, it's an old custom job I did years ago (notice the pipework going through it, lol I used to think stuff like that was cool... but what happens when the Ranco breaks you supercool idiot????) From HLT drain, water goes into the "Super-Badassed-THANK YOU-Bobby_M-RIMS tube" pulling almost it's max current @120vac if it needs to. Essentially boosting incoming water temperature "if needed" on its way to the HERMS coil, before returning to the HLT. The RIMS tube element is controlled by the PID in the black box on the left of the 2nd vessel down (Mash Tun). More on the box in a minute. The temperature sensor (I chose a PT100) for the box PID is located at the top of the MT, on the left side of the converted three-way ball valve so it "receives" what the mash is receiving. That is the whole RIMS-HERMS control I was after with a ZERO% chance of scorching...EVER! Overkill... yes! It will do as it is told, and it will put the lotion on the skin when told to, so I don't care what it cost to relieve any variables. The three-way valves on the HERMS coil change it into my counterflow wort chiller when the time comes, so I get double duty out of it.

As for the wort side, that's easy to explain. Bottom of MT to wort pump (furthest left in picture), then through the coils from top to bottom (anti RIMS-HERMS water direction) before being filtered inline with a wort strainer on its way to the temperate sensor and MT. The strainer is bypassed initially to allow for debris to return to the MT before a filter bed is set. Nothing special, just custom for what I want to do.

After knock out from the MT and transfer, there is going to be a ton of stuff left in the lines.

That's where this little guy comes in. I'm going to hook CO2 up to my brewery to push lines clear, or unstick a stuck sparge, at low pressure of course. When I'm in the kettle, I'll clean the wort lines and get everything ready for whirlpool and chilling. Here's where the OVER-SIZED wort strainer comes in. I'm hopeful it will take 100% of the kettle hop bill during whirlpool, as well as break material. It's 4" and girthy, we will see. This CO2 valve with ball lock fitting will allow me to push almost 100% of my product to the fermenter. With this valve I will also have the ability to flood my MT with CO2 for low oxygen experimenting. I want to try lots of things!

Here some up close pics of the control box. It is wired with input from two separate legs of power from the breaker for each circuit. Circuit 1 powers lower red receptacle for RIMS element. It will not come on unless Circuit 2 RIMS pump is on, the key is turned, and the RIMS element button is on. Safety third! The volt meter comes on with RIMS element to tell me what it is pulling as a reference. Everything else on the box is powered by Circuit 2. Buttons are top left Wort Pump, bottom left RIMS Pump, bottom right RIMS Element, top right HLT Ranco ETC.

Here's a top and side view of the heat exchanger and pumps.

I attached this to the top of the RIMS tube to allow air to escape.

I have thought about this for a very long time, of how I wanted some things changed (in my brewing setup) for ease or just ease of mind. Hope you guys enjoy! I can't wait to try it out very soon. Questions, comments, I take them all. I would like to thank Bobby_M at brewhardware.com for the purchasing of my gadgetry, but mainly for the SS tubing bent w/fittings welded on. Very good price on such custom things is rare, and he ships fast!

I think I have one more project in me, my chest freezer fermentation chamber compressor broke, so I bought a window unit for it and love it better. Write up and pics COMING SOON!

Last edited: