Yes, you could check every two days, just try to be patient. Eventually, you’ll get a better feel for the process.

It’s not a bad idea to have extra bottles on hand to help with the impatience. I have several cases from before I started kegging so that I would always have beer on hand while waiting for others to finish.

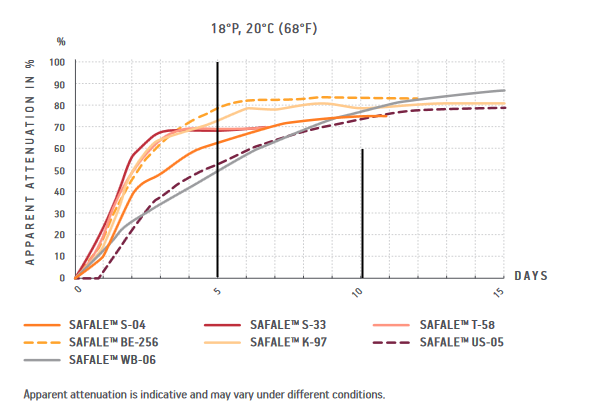

While it is definitely beneficial to give it that extra time, you will find that some beers can absolutely be done in 4 or 5 weeks. Most of my ales are done fermenting in 10 days. If I bottle, some can be carbed in a week. They may taste ok by this time, but if I wait another week they are even better. Depending on the beer, another week even makes them better. Same with when I keg. Most times for me, three weeks carbing and conditioning is the sweet spot. But again, a lot of beers benefit from more time.

In the end, it’s your beer and you are the one who needs to like it. Bottle it up, chill one after a week and try it. Chill another one a week later and try it. If it’s good, chill a few more and enjoy them. Then repeat after another week. You should notice an improvement in both quality and clarity over that time. It took me close to a year of brewing to get this. I often noticed that I could still taste the grain and/or the yeast. Extra time cleans that up.

Don’t get caught up in the whole “grain to glass in 7 days” thing. That mostly comes from keggers who use fast yeast and then burst carb. It may work for them and their beer may taste good to them, but it was never my cup of tea. The beer never tasted great…at least not to me.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)