If the DC power supply is rated for something like 85 - 250VAC input, just connect the two hots to the power supply. If one of the inputs is labeled "Neutral" connect a hot to it. Do not mix up ground and neutral as doing so will cause your GFCI to trip.The split phase (2 hot, 1 ground) complicates things in my head. I'm pretty sure I can use a normal 110-220v ac/dc powersupply to get 5v and hook up hot1 and hot2 to hot and neutral on the ac/dc powersupply. I'm a bit confused on the SSR setup, would I just hook up 1 hot to the SSR and treat the other one as neutral? Then each half phase the SSR is alternating between switching hot and neutral?

Maybe a contactor is more appropriate? What about using 2 SSR, 1 for each half phase, that would also help distribute heat.

With an SSR, you only want one hot going thru an SSR, as using two SSRs will double the power "wasted" in the SSRs (25 - 35W in each one.) An SSR is not a perfect, or galvanically isolating switch (doesn't remove voltage). Think of an SSR as a current modulator with high current and very low current conduction states. Here's an equivalent circuit model for an SSR that will help you understand what an SSR looks like electrically:

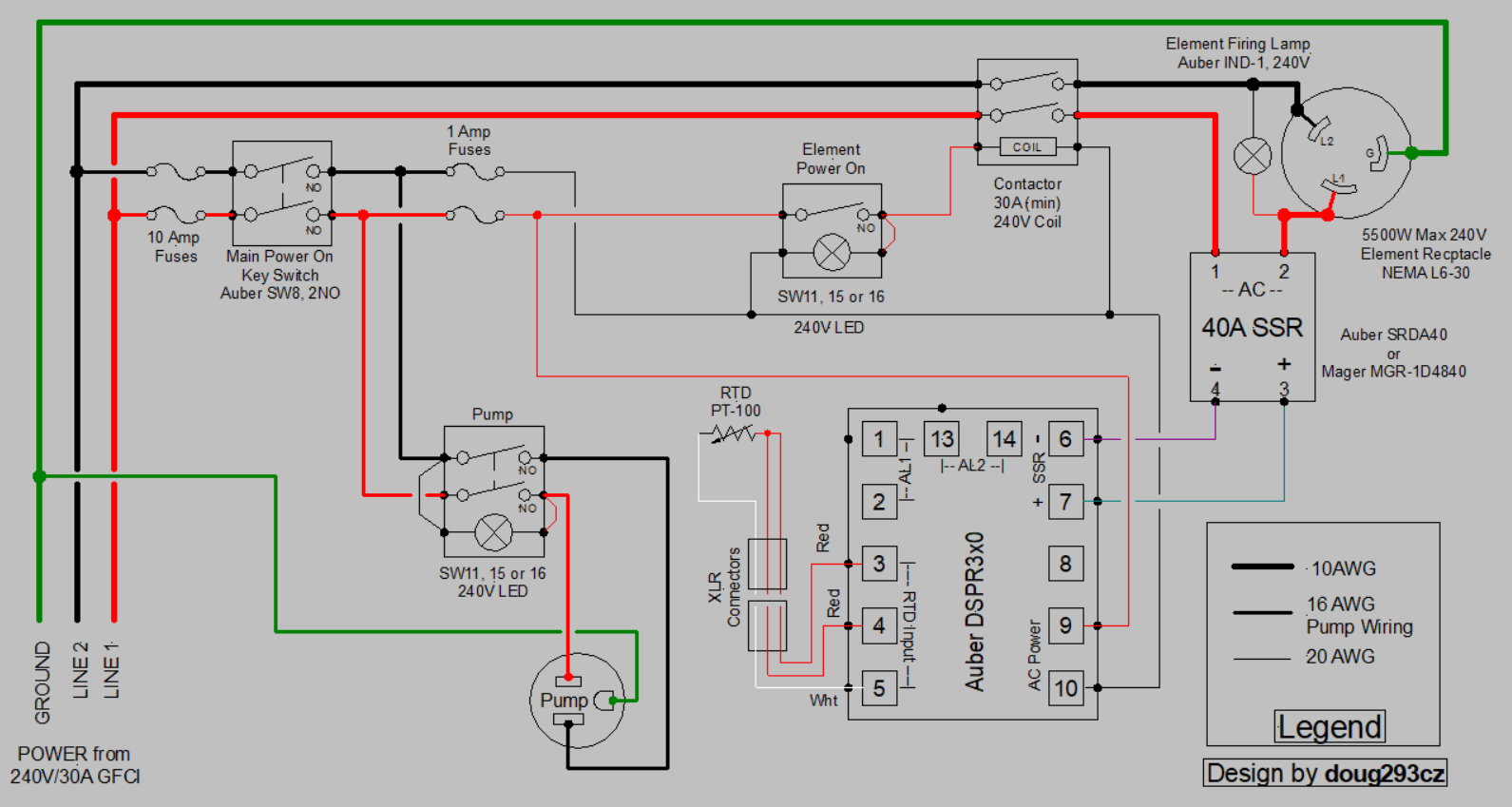

Here's a simple design that shows how an SSR and contactor can be used:

The contactor provides galvanic isolation of the element from the input power. This can be advantageous, as the most common failure mode for SSRs is latched in the "ON" state. Without the galvanic isolator, you would have to unplug a live 240V circuit from the wall while it is pulling ~23A, which will give you some startling arcing when you do it.

You would substitute your microcontroller for the DSPR.

Brew on

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)