The Pol

Well-Known Member

- Joined

- Feb 12, 2007

- Messages

- 11,390

- Reaction score

- 120

I have a question for you guys doing the no-chill method. Would something like this work at all?

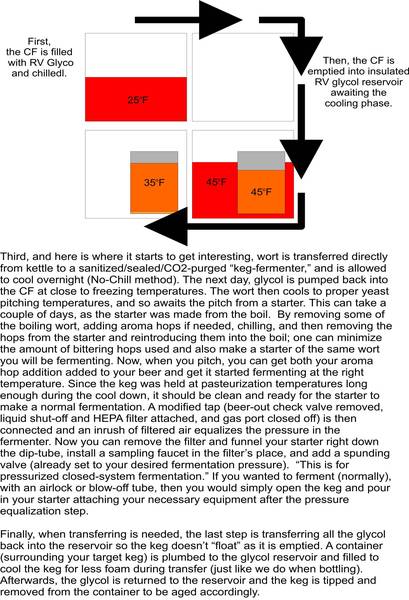

EDIT: CF is a chest freezer in case you are wondering, lol.

I use a different fermentation technique, but would this no-chill-then-chill method work at all? I just had the idea after all the talk about no-chill and wondered. Pol, can you chime in on this?

I am a simpleton, what is the no chill and then chill method? I dont understand the flow chart at all.

and woke up :smack: !!!

and woke up :smack: !!!