wongjau

Well-Known Member

He said "a little alcohol" because that's the beginning of fermentation vs what had been up to that point merely saccharification.

Fridge is less likely to work since the mold needs higher temps to produce sugar unless you get 100% conversion at high temp as a 1st step (I drew a diagram of how you could do this earlier in the thread, but haven't done the setup yet).

His process is similar to mine, but I go higher in temps the first 24-48 hours. Koji A. oryzae wants 96 ideally for max sugar production. The lower you are below that, the higher your protein:sugar ratio will be.

Yep!

I suspect the temps were too cold for his yeast to get past the lag/log phase of growth.

Not necessary to have 100% conversion for rice wine. It is different than typical beer/wine/cider fermentation.

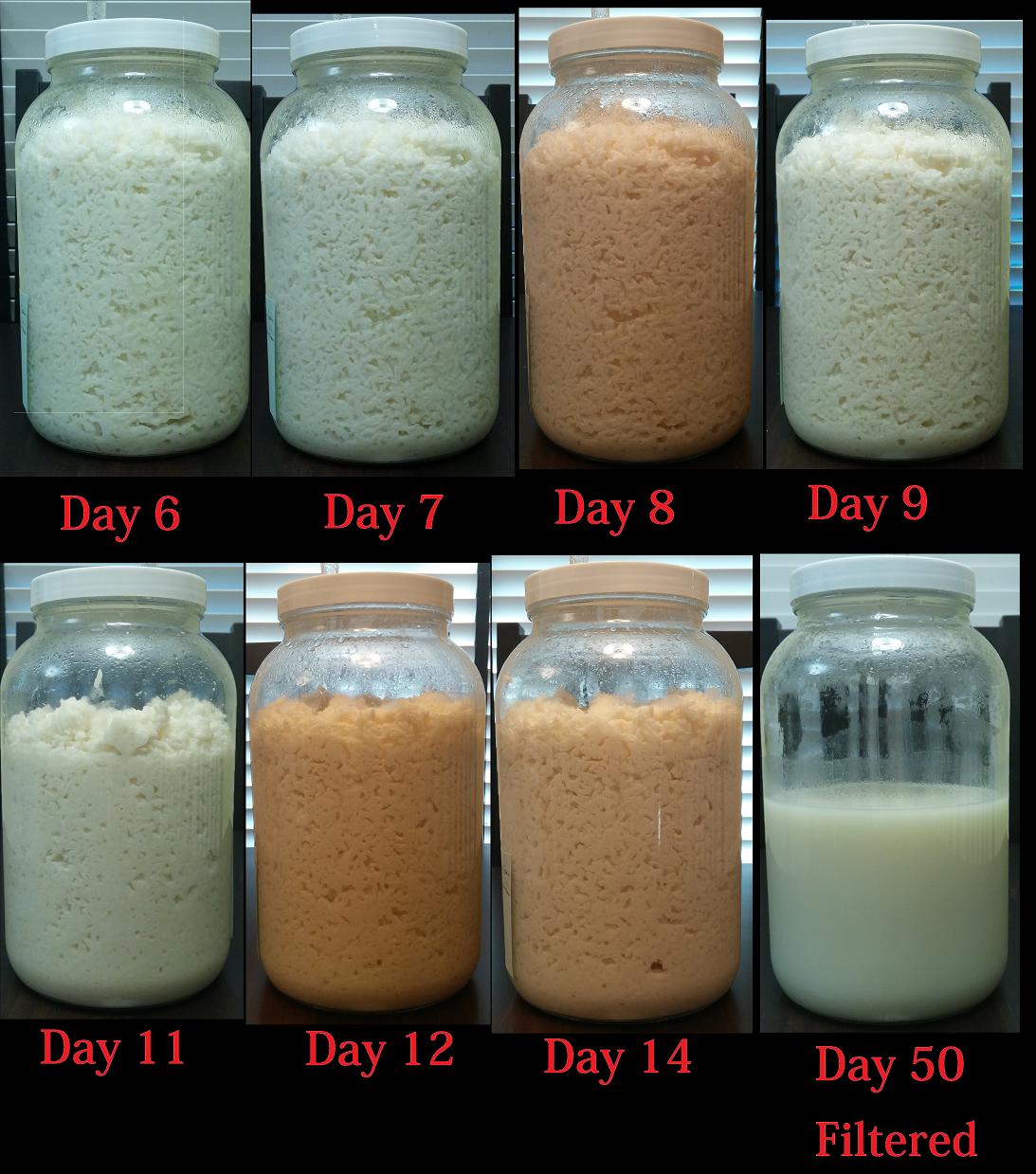

It is a parallel fermentation, solid state initially. The yeast converts the sugars as they are produced by the Rhizo. The gradual fermentation allows a higher final alcohol level.

There has to be enough sugar, oxygen, and heat for yeast to take off. This is like building a starter when brewing beer.

Then the large yeast population can continue with the fermentation as the rice gets slowly converted to sugar. This is like syruped ferment for wines.

That's why traditionally, the rice steaming process is important for creating separate grains that facilitate access to the Rhizo mycelia and amylase.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)