Prateek Garg

Member

- Joined

- Jul 31, 2019

- Messages

- 11

- Reaction score

- 1

Hi, people!

I'm a homebrewer in India. But I've been brewing Kombucha (a fermented tea) instead of beer for now. I retrofitted an old fridge with a beer tap to make a kegerator of sorts.

I brew my Kombucha in glass jars, and then pour it in a used pin lock corny keg I picked up from a store. I then try to force carbonate my Kombucha by adding CO2 from a pressurized CO2 cylinder.

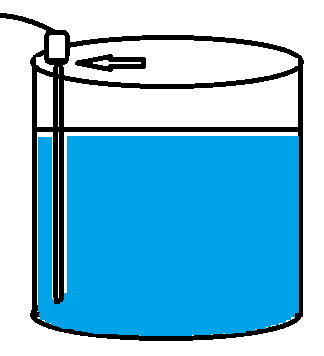

Here is how my system looks like during the dispensing. And there's a head of 90+%; basically only foam seems to come out of my tap and the liquid beneath is super flat after the foam settles.

Apologies for a long, long post ahead but I've mentioned all the troubleshooting I've tried to do by reading this forum and watching youtube and nothing has worked so far:

1. I've tried slow and fast carbonation both (fast = adding about 30psi of pressure and rocking the keg for 5-10 minutes; slow = keeping the keg at 16-18psi for a 10 days). Both of these give the exact same result with the same amount of foam dispensed and flat liquid.

2. I've read almost everything there is about pressure balancing the kegerator. I have mostly used this source: http://www.mikesoltys.com/2012/09/17/determining-proper-hose-length-for-your-kegerator/ (recommended by Draft System Balancing or How To Fix Foamy Beer)

to make all sorts of calculations about my hose length. Tried with different hose inner diameters and dispensing pressures and no matter what, there is **** load of foam from the tap, even when I use like 2 psi dispensing pressure at a 8 feet length of 4mm hose (which, according to the calculations should balance about 14 psi of pressure). As you might see from the pictures, I have two connectors in the middle; that's because my disconnectors are made for the 1/4'' beer lines but 1/4'' lines would need about 35+ feet of hose length for 14 psi (very long even for 10psi). So, I've used 4mm lines (about 0.15'') and 8 feet of those but no positive result whatsoever. At some point I troubleshooted for the multiple connectors in the line, and I used the same single 1/4'' line, 8 feet of it, but a dispensing pressure of 1.5 psi, but still that same **** load of foam with super flat liquid after the foam disappears.

3. When I open my keg after I try and fail at dispensing any decent liquid out and just dip my glass in the keg to get some liquid out, that liquid is super tasty and very well carbonated, but no matter what dispensing pressure or hose length I use I don't get a decent pour out (same too much froth but no carbonation in the liquid)

4. This might be an obvious point but I'll state it anyway. When I only put the Kombucha in the keg and dispense it out, it's just good pure liquid out, but as soon as I carbonate the liquid in the keg, I don't get almost any liquid out.

5. I do manage to get only liquid out in just one way: When I put the dispensing pressure like super, super low like barely just putting enough CO2 in to just get the liquid out. This pressure might be equivalent to maybe 0.1 psi or something; no way of knowing; the least count of my regulator is 1 psi. However, when this way only liquid comes out, the liquid is still flat (no carbonation retained) but when I immediately after open the keg and dip my glass in, the liquid inside is properly carbonated; it's just not retained when it comes out.

6. I've checked the temperature and it's super low; like 4-5 degree celsius (39-42 degree fahrenheit), no issues there I believe.

7. I've also tried doing the same thing with a store bought bottled beer; made it flat by leaving it open for a while, poured it in the keg, carbonated it. Same result. So I don't think it's about Kombucha per se (or its ability or inability to retain carbonation; this is also refuted by the fact that the Kombucha liquid inside in indeed properly carbonated)

8. I've tried with two different kegs. Two different taps. Two different sets of disconnectors. Same result. It's possible that all are bad for some reason. But unlikely, I guess.

Thanks for reading this long article; please let me know what you think might be going wrong.

I'm a homebrewer in India. But I've been brewing Kombucha (a fermented tea) instead of beer for now. I retrofitted an old fridge with a beer tap to make a kegerator of sorts.

I brew my Kombucha in glass jars, and then pour it in a used pin lock corny keg I picked up from a store. I then try to force carbonate my Kombucha by adding CO2 from a pressurized CO2 cylinder.

Here is how my system looks like during the dispensing. And there's a head of 90+%; basically only foam seems to come out of my tap and the liquid beneath is super flat after the foam settles.

Apologies for a long, long post ahead but I've mentioned all the troubleshooting I've tried to do by reading this forum and watching youtube and nothing has worked so far:

1. I've tried slow and fast carbonation both (fast = adding about 30psi of pressure and rocking the keg for 5-10 minutes; slow = keeping the keg at 16-18psi for a 10 days). Both of these give the exact same result with the same amount of foam dispensed and flat liquid.

2. I've read almost everything there is about pressure balancing the kegerator. I have mostly used this source: http://www.mikesoltys.com/2012/09/17/determining-proper-hose-length-for-your-kegerator/ (recommended by Draft System Balancing or How To Fix Foamy Beer)

to make all sorts of calculations about my hose length. Tried with different hose inner diameters and dispensing pressures and no matter what, there is **** load of foam from the tap, even when I use like 2 psi dispensing pressure at a 8 feet length of 4mm hose (which, according to the calculations should balance about 14 psi of pressure). As you might see from the pictures, I have two connectors in the middle; that's because my disconnectors are made for the 1/4'' beer lines but 1/4'' lines would need about 35+ feet of hose length for 14 psi (very long even for 10psi). So, I've used 4mm lines (about 0.15'') and 8 feet of those but no positive result whatsoever. At some point I troubleshooted for the multiple connectors in the line, and I used the same single 1/4'' line, 8 feet of it, but a dispensing pressure of 1.5 psi, but still that same **** load of foam with super flat liquid after the foam disappears.

3. When I open my keg after I try and fail at dispensing any decent liquid out and just dip my glass in the keg to get some liquid out, that liquid is super tasty and very well carbonated, but no matter what dispensing pressure or hose length I use I don't get a decent pour out (same too much froth but no carbonation in the liquid)

4. This might be an obvious point but I'll state it anyway. When I only put the Kombucha in the keg and dispense it out, it's just good pure liquid out, but as soon as I carbonate the liquid in the keg, I don't get almost any liquid out.

5. I do manage to get only liquid out in just one way: When I put the dispensing pressure like super, super low like barely just putting enough CO2 in to just get the liquid out. This pressure might be equivalent to maybe 0.1 psi or something; no way of knowing; the least count of my regulator is 1 psi. However, when this way only liquid comes out, the liquid is still flat (no carbonation retained) but when I immediately after open the keg and dip my glass in, the liquid inside is properly carbonated; it's just not retained when it comes out.

6. I've checked the temperature and it's super low; like 4-5 degree celsius (39-42 degree fahrenheit), no issues there I believe.

7. I've also tried doing the same thing with a store bought bottled beer; made it flat by leaving it open for a while, poured it in the keg, carbonated it. Same result. So I don't think it's about Kombucha per se (or its ability or inability to retain carbonation; this is also refuted by the fact that the Kombucha liquid inside in indeed properly carbonated)

8. I've tried with two different kegs. Two different taps. Two different sets of disconnectors. Same result. It's possible that all are bad for some reason. But unlikely, I guess.

Thanks for reading this long article; please let me know what you think might be going wrong.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)