kryolla

Well-Known Member

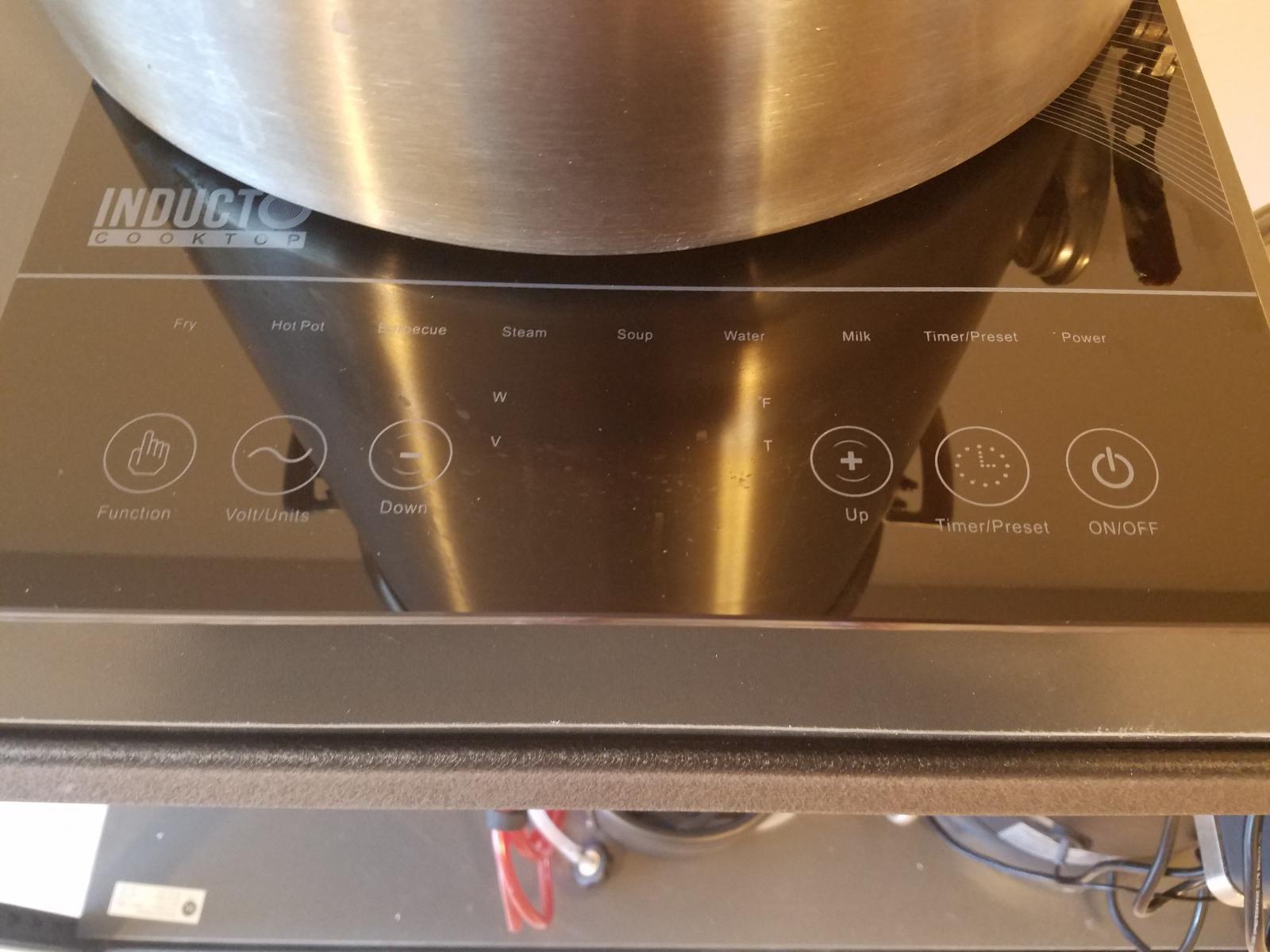

my plan was to mash at 1.75 q/lb of grain then let it sit at 152 for 30 min then start recirc..It didnt work out I was loosing too much heat so I started to recirc once it got to 149...I missed my pre boil gravity and had to add a lb of DME to make up for it..I guess next time I'll try a thicker mash..Other than that my brew day is going good Im digging the GF

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)