Frozen Yeast Bank SOP

In another thread, I was asked by a member to write down my process for creating a frozen yeast bank.

This is the SOP I have established through my own research and experience. I'm definitely not promoting this as the only way or best way, but it works for me. With cleanliness and sanitization being of utmost importance in every step, I have had excellnt results and no infections.

Equipment, items required

Ingredients

SOP

This process takes 2-3 hours over the course of 5-6 days.

Day 1

I usually brew on Friday night or Saturday morning, so I start this process on Monday or Tuesday night. If making starter from frozen vial, see note at end.

Day 2

Cryo preservative. This is used to prevent ice crystals from forming and destroying yeast cell walls durring freezing.

Day 3

Move flask to refrigerator to crash.

Day 4

Day 5/6

*Making a starter from frozen vial

Ive found that it definitely takes 48hrs to fully propogate enough yeast from the small amount in a vial. I make a 1L ( 101g DME) starter for Kveik yeast, a 1.5L starter for standard ale yeasts and haven't yet tried a lager yeast, but would plan on either a 2L ( 202g DME) starter or 2 step starter for that.

I pour the entire starter into my 5-6 gallon batch of wort.

In another thread, I was asked by a member to write down my process for creating a frozen yeast bank.

This is the SOP I have established through my own research and experience. I'm definitely not promoting this as the only way or best way, but it works for me. With cleanliness and sanitization being of utmost importance in every step, I have had excellnt results and no infections.

Equipment, items required

- 2-5 Liter Erlenmeyer flask Borosilicate or Pyrex

- Stir plate. Optional but recommended. About $20 on Amazon

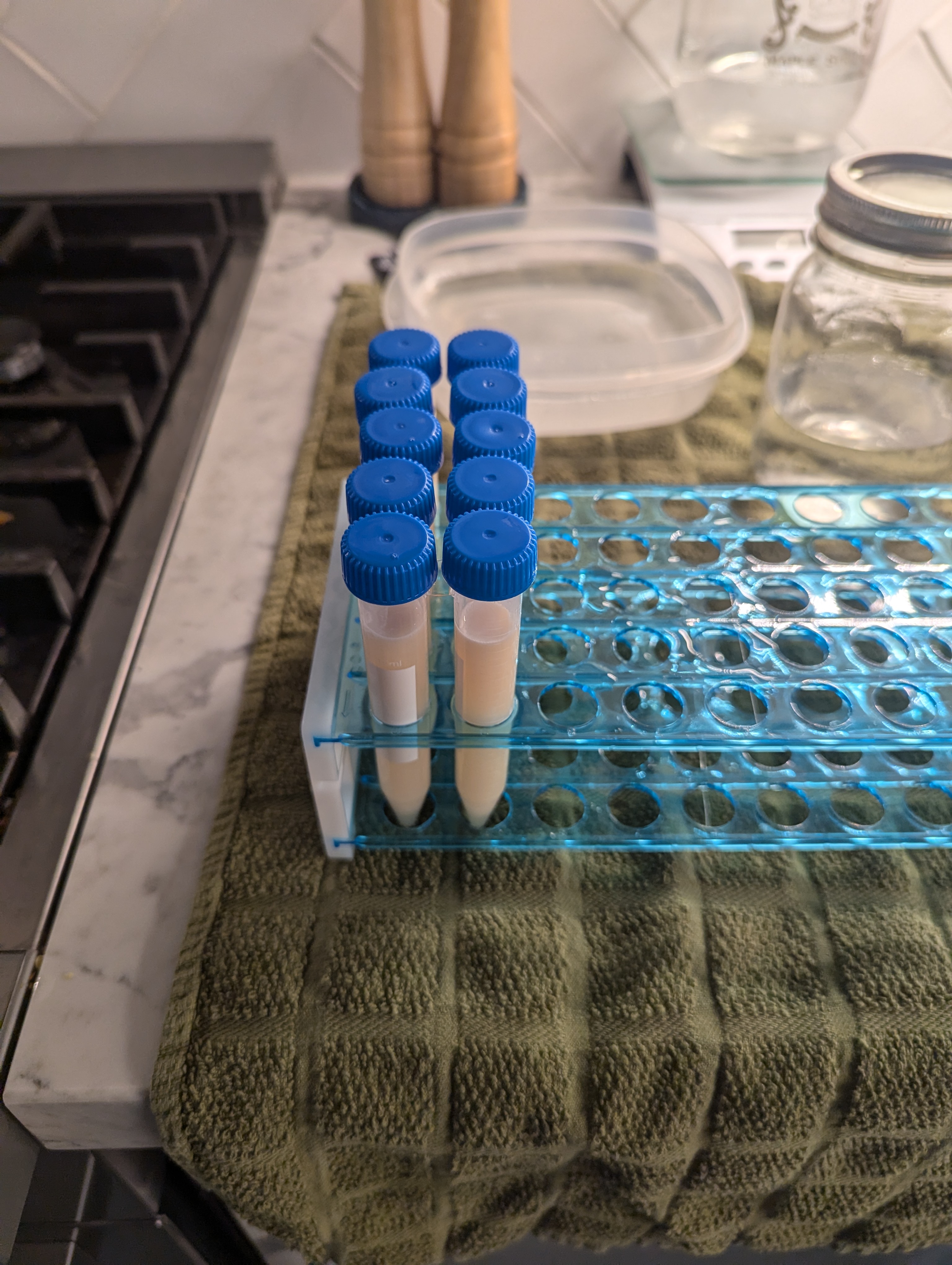

- 10+ 15ml plastic vials. Test tubes or centrifuge. Screw top recommended. About $13 on amazon depending on quantity.

- Stock pot

- Accurate scale

- 1 qrt freezer bags

- Sealable container large enough to fit 10 vials +

- Aluminum foil

- Small mason jar

- Bottle isopropyl alcohol

- 10 ml Syringes. Sterile

- Starsan

- Spray Bottle

- Thermometer

- Funnel. Optional

- Heat resistant gloves or pads.

Ingredients

- Yeast pack. Liquid or dry

- DME.

- Yeast nutrient

- Olive oil. Optional

- Glycerin

- Water

SOP

This process takes 2-3 hours over the course of 5-6 days.

Day 1

I usually brew on Friday night or Saturday morning, so I start this process on Monday or Tuesday night. If making starter from frozen vial, see note at end.

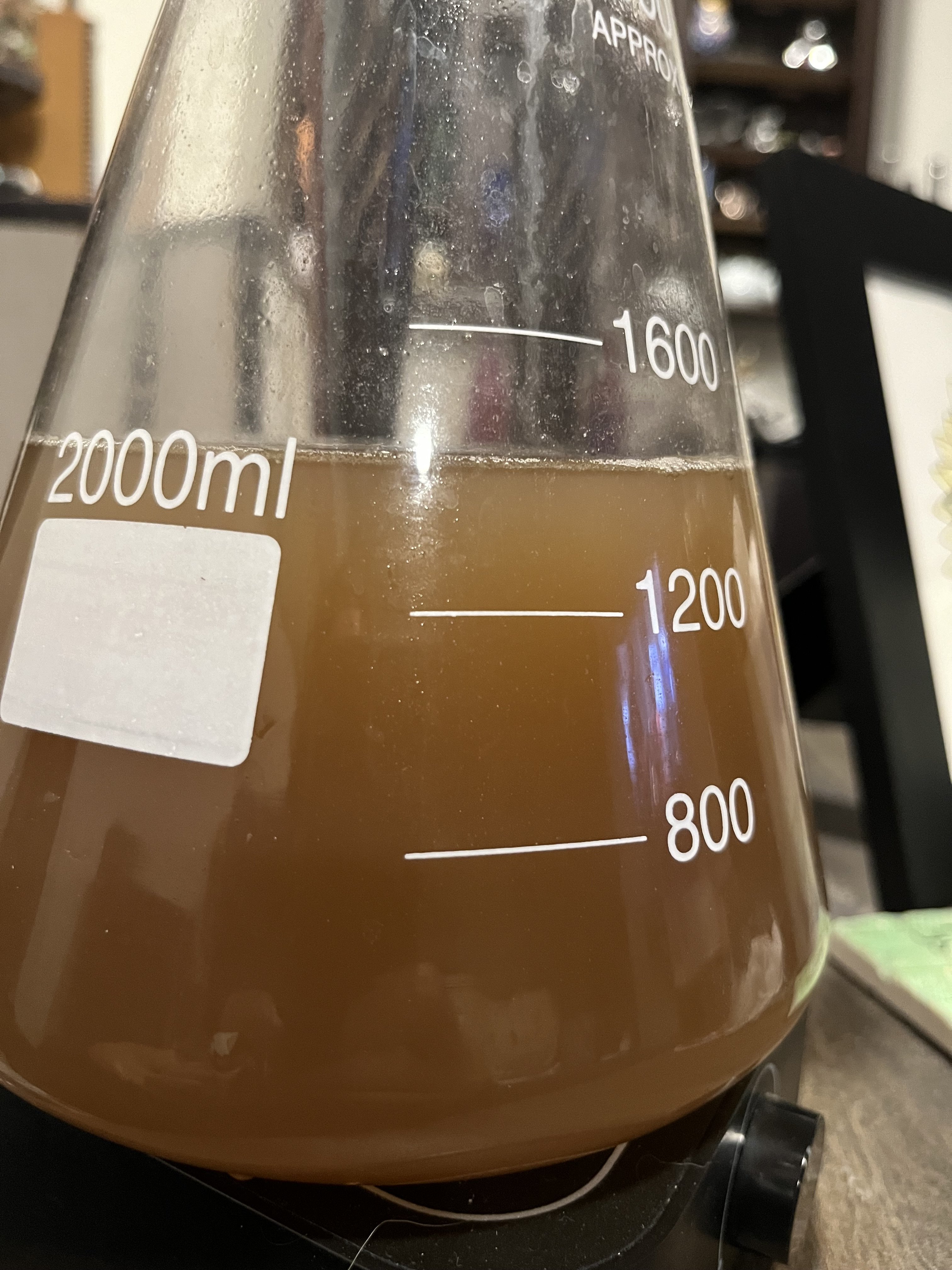

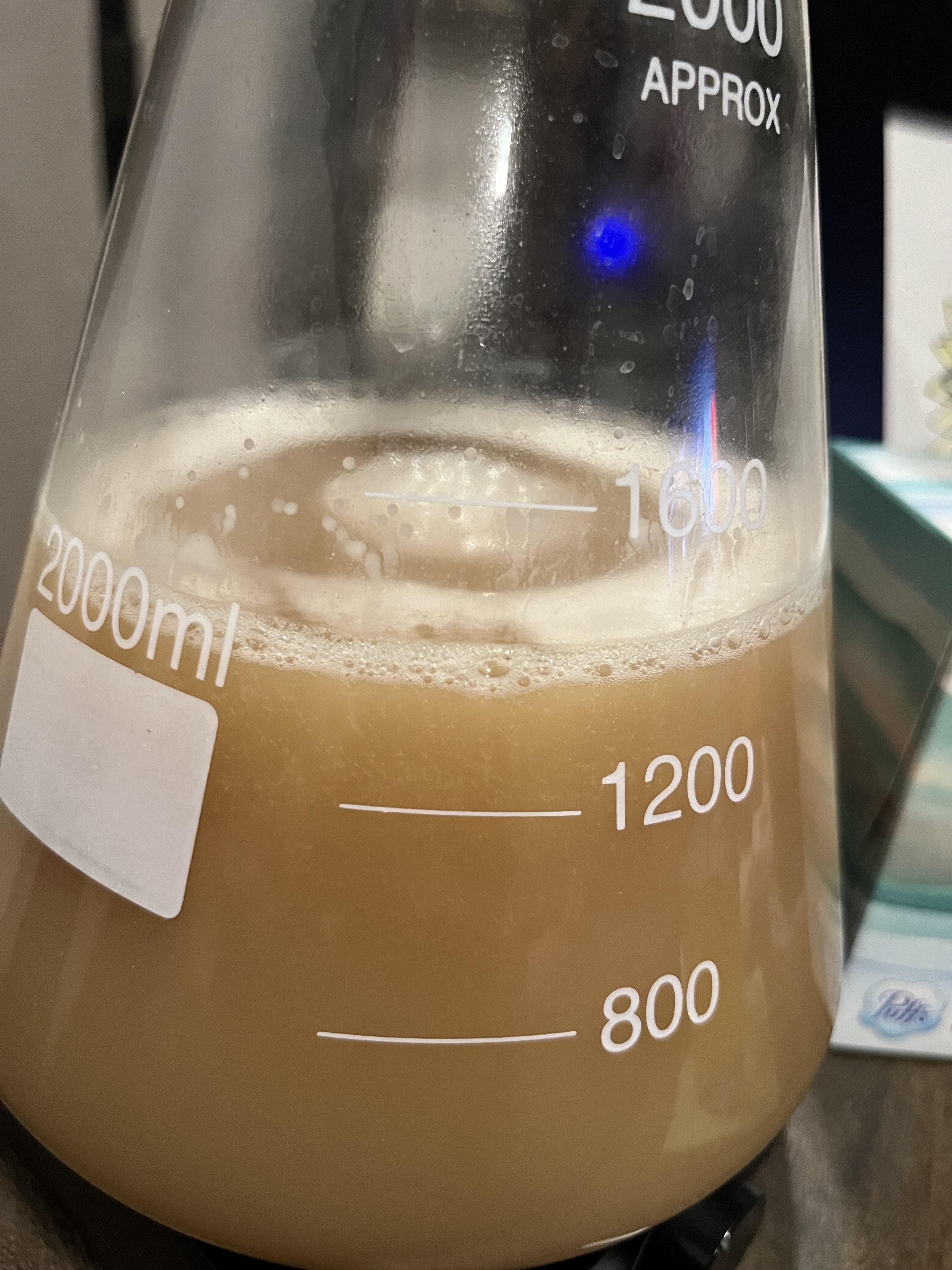

- Make a 1.5L, 1.037ish starter with lab packaged yeast. I use 151g of DME and with boil off, end up with about 1.5L of 1.037 wort.

- Remove yeast from fridge.

- Collect about 1.7L water in Flask. Pour 3/4 of the water into stock pot and leave remainder in flask. Drop stir bar into flask if using stir plate. Loosely cover top of flask with starsan sprayed foil. Set flask and stock pot on separate burners. Heat flask at medium low and pot at medium high. Add 151g DME to pot while water is still cool and stir until dissolved. Stir well while heating and during boil.

- At start of boil add 1/8 tsp yeast nutrient and 1-2 drops of olive oil to pot.

- Boil pot and flask 10 minutes.

- After boil is complete, carefully pour wort from pot into flask. I use a sanitized funnel here. Use gloves or pads with hot containers.

- Set pot in sink and fill about 1/3 with cold water.

- Set flask in pot. Add ice to pot just above wort volume in flask. Don’t let flask float.

- Cool wort in flask to room temp, swirling flask to speed up cooling. I usually use my judgment as to when it’s cool, but a sanitized thermometer could help with this.

- At room temp, with sanitization in mind, remove foil from flask and pitch yeast into flask.

- Replace foil. Secure but not crimped too tight.

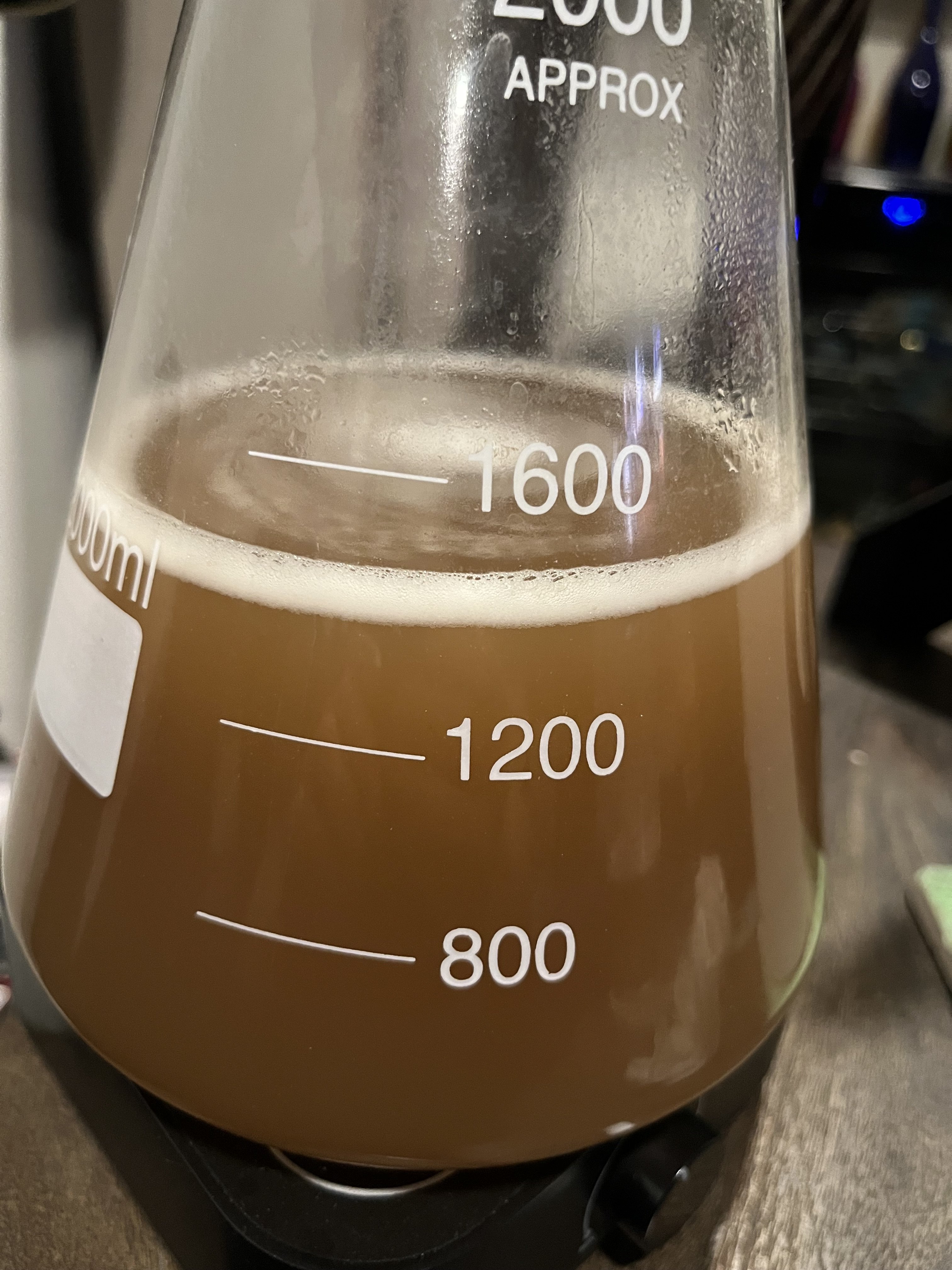

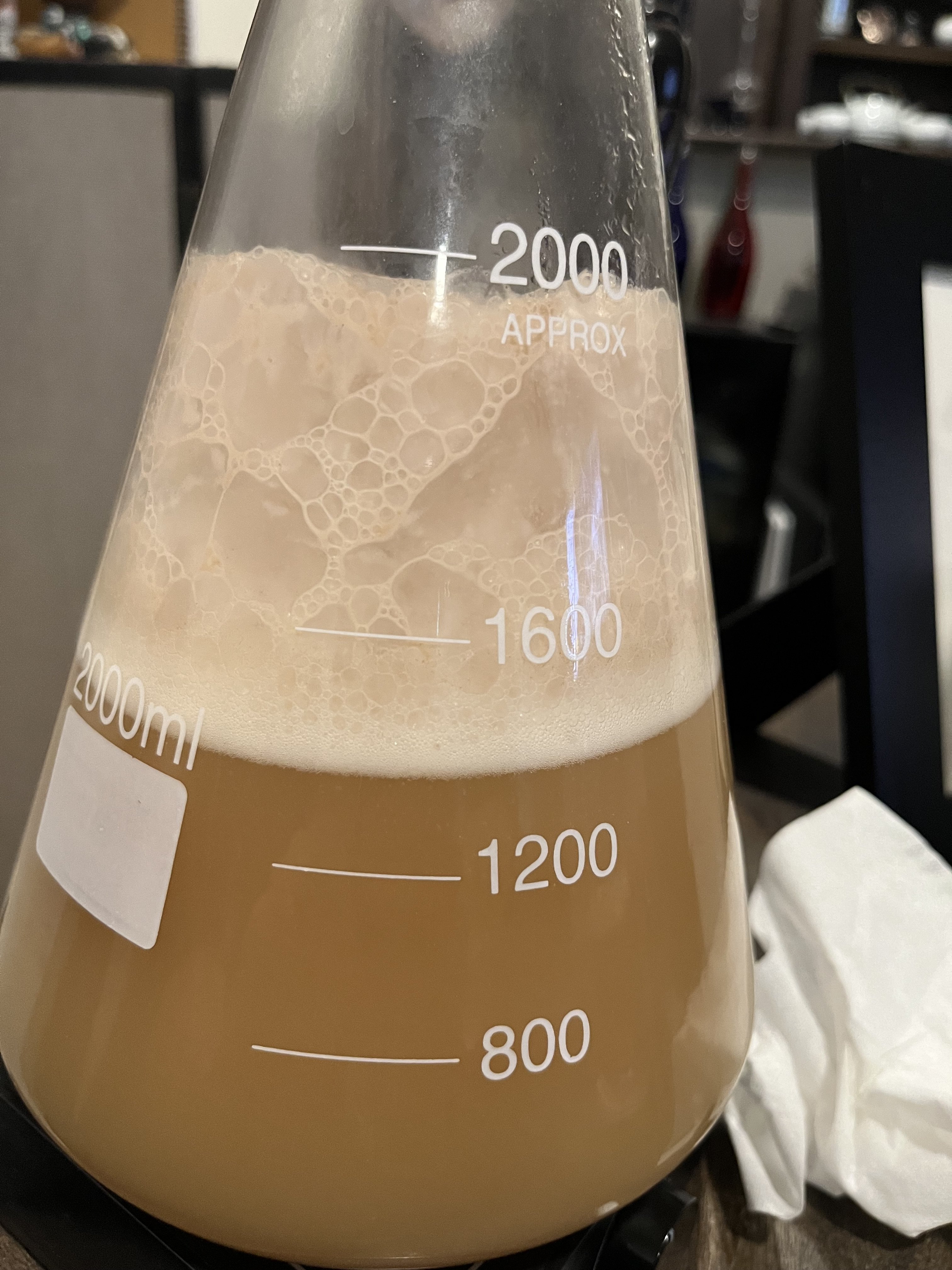

- Set flask on stir plate. Use lowest speed to maintain vortex. This will allow CO2 to escape. If not using stir plate, swirl vigorously and often over sink.

- Allow yeast to propagate for about 48 hours.

Day 2

Cryo preservative. This is used to prevent ice crystals from forming and destroying yeast cell walls durring freezing.

- Zero scale with small mason jar.

- To jar add about 100 ml water. Note weight. Add 25% of water weight in glycerin.

- Seal jar and set in stock pot with enough water to about half height of jar. Don’t let jar float.

- Put lid on pot and bring to a boil and boil for 10 minutes.

- Turn heat off and leave to cool until next day.

Day 3

Move flask to refrigerator to crash.

Day 4

- Ready all necessary supplies and equipment.

- Will need a bowl or open container to fill with Starsan solution. Spray bottle of Starsan solution. Small bowl or measuring cup. Vials. Vial holder. Syringe. Small flask or jar. Isopropyl alcohol. Sealable container that holds 10+ vials+ .

- Remove flask from fridge and gently pour off (decant) 95% of liquid. Try to pour off as much as you can without losing yeast.

- Swirl flask to put remaining liquid and yeast into a slurry.

- If vials are not sterile, fill a container with Starsan solution and sanitize vials and caps/ lids.

- Set 10+ vials in rack/holder for filling.

- Shake up cryo-preservative.

- Open sterile syringe and jar of cryo-preservative.

- Add about 75ml yeast slurry to small, sanitized bowl or measuring cup.

- Keep remaining slurry in flask or in separate, sanitized container for next batch and return to fridge.

- Use graduated syringe to add 6ml yeast slurry to each vial and top with 6ml cryo-preservative. Seal each vial with sanitized lids/ caps.

- Gently shake vials to mix slurry with cryo-preservative.

- Fill sealable container with sealed vials and isopropyl alcohol. Seal lid and place in freezer. Save alcohol container. The alcohol helps to ensure a slow and even freezing of the vials.

- Freeze for 24-48 hours.

- Discard remaing yeast slurry and cryo-preservative.

Day 5/6

- Remove container of vials/ isopropyl alcohol from freezer.

- Use sharpie to label 1 qt ziplock bag with strain type/ information.

- Pull vials from alcohol and dry with paper towel. Add vials to ziplock bag.

- Place bag with vials in freezer.

- Return alcohol to original container for later use. Funnel helps here.

*Making a starter from frozen vial

- Revome vial from freezer

- Follow day 1, starter method.

- When wort is cooled, vial should be thawed. Gently shake to ensure good mix and pitch into flask.

Ive found that it definitely takes 48hrs to fully propogate enough yeast from the small amount in a vial. I make a 1L ( 101g DME) starter for Kveik yeast, a 1.5L starter for standard ale yeasts and haven't yet tried a lager yeast, but would plan on either a 2L ( 202g DME) starter or 2 step starter for that.

I pour the entire starter into my 5-6 gallon batch of wort.

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)