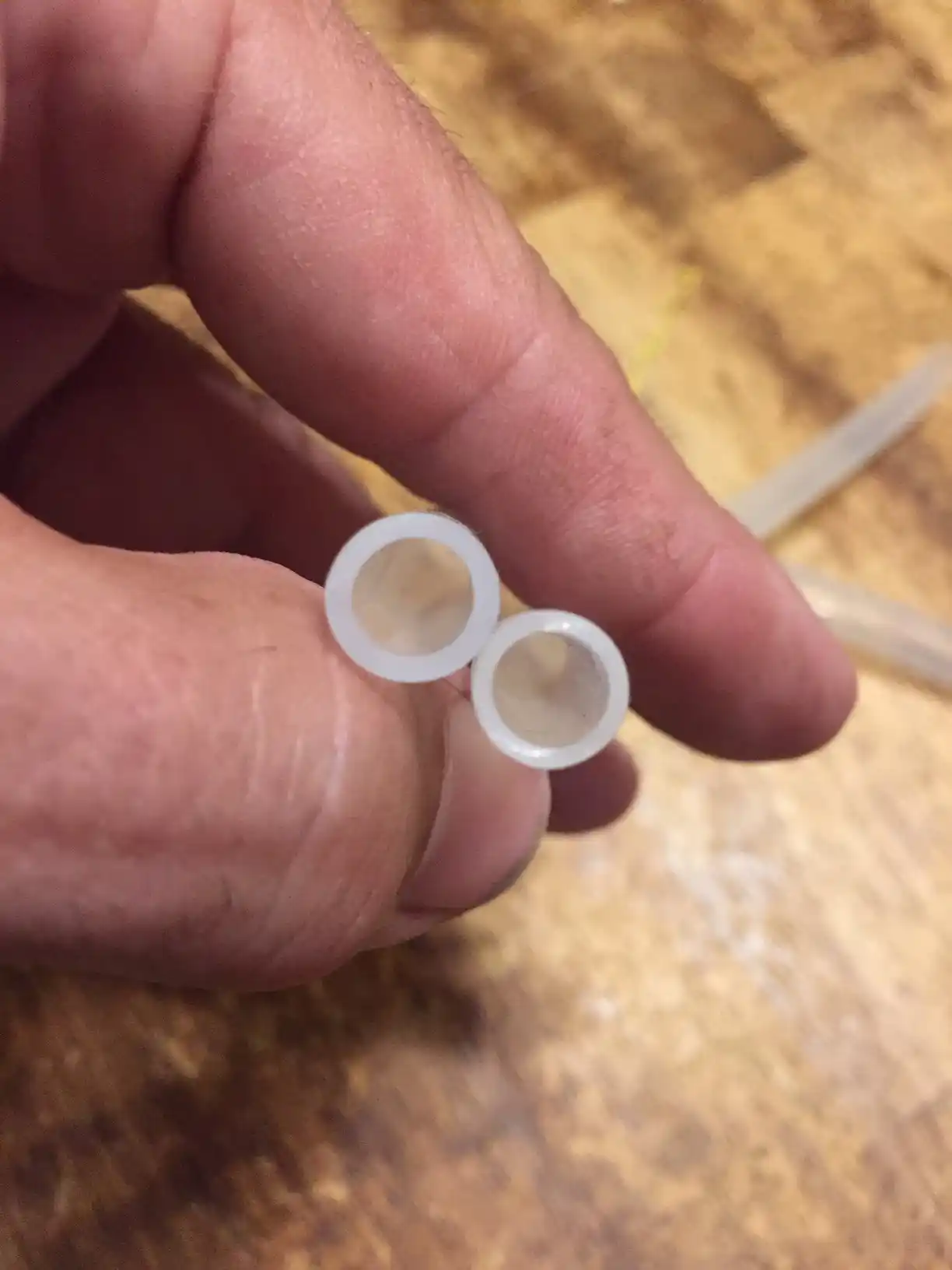

I'm running the ones with the round SS float, about the size of a ping pong ball. Has a short 1" SS pickup tube to attach the tubing, silicone in my case. The pickup is attached the float with a small SS split ring. As you can see in the photo, the pickup tube is about 1-1/2" to 2" below the surface. This "should" be ideal. Not so.

View attachment 757223

I opened a couple kegs that suddenly stopped flowing beer. What I found was that the float was on it's "side". Yes it's a round float but there is a horizontal seam that somehow rotated vertical and thus pulled/lifted the pickup to the surface, allowing air into the tubing and floating everything to the surface. Why this happened I'm not sure but I have some theory...

I supposed if you are pouring too much beer too fast, like a growler fill, it's possible the headspace pressure will drop and CO2 break out of the beer and fill that headspace with foam. I guess the beer is flowing out faster than the regulator can replace CO2? The problem seems to occur mostly with Hefes and other higher carbed beers. But it recently happened with a lower carbed English style beer too. I theorize that this foam lifts the float, thus lifting the pickup above the beer and the whole thing sucks air and then the entire tubing floats to the top. You don't realize it's happening until the tap stops flowing beer and all you get is CO2 and some foam coming out. By this time the entire silicone hose inside the keg has filled with CO2 and is now floating, pushing the pickup even higher. As you can see in the picture, bubbles easily stick to SS float and pickup tube.

Sometimes I've been able to wait it out and I guess the foam dissipates and the pickup/tubing drop below the surface and fill with beer again. Sometimes I've had to pull the keg, flip it upside down so the float can "rise to the bottom" so to speak, extending the silicone tubing and expel the CO2 and fill with beer again. Sometimes nothing, not filling the keg, not laying it on it's side, rocking it, rolling it, not shaking the keg, nothing will get the tubing and pickup to drop below the surface to expel the gas and let beer back in.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)