Hi all,

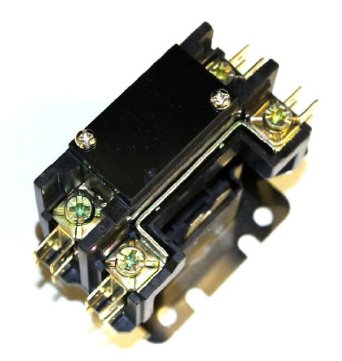

I have set up an electric keggle in the style of thelectricbrewery.com. I have a 240v 5500 watt low density heater element plugged into my Inkbird PID with 40A SSR relay with heatsink and the included Type K thermocouple (all purchased as a kit from Amazon. Between the controller and the keggle is a manual shutoff switch.

Pictures of setup and wiring diagram

View attachment diagram.pdf

The PID kicks the SSR and heating element on at the right temperature, my set variable, but it will continue to heat well above the set variable. The element continues to fire even after the little LED labeled OUT (on the Inkbird PID) goes off. If I toggle my manual switch to OFF, of course the element goes off. When the process variable drops below my set variable the element comes on and again and will continue to heat until i turn the manual switch off again.

I ran the auto-tune function and it still continued to heat. I eventually just cancelled the auto-tune

Any suggestions? is my relay junk? If it was faulted, wouldn't the relay always be on regardless of whether the PID is signaling to do so?

I would also appreciate any tips on configuring the Inkbird PID. I will post back with how I have it at the moment.

Thank you

I have set up an electric keggle in the style of thelectricbrewery.com. I have a 240v 5500 watt low density heater element plugged into my Inkbird PID with 40A SSR relay with heatsink and the included Type K thermocouple (all purchased as a kit from Amazon. Between the controller and the keggle is a manual shutoff switch.

Pictures of setup and wiring diagram

View attachment diagram.pdf

The PID kicks the SSR and heating element on at the right temperature, my set variable, but it will continue to heat well above the set variable. The element continues to fire even after the little LED labeled OUT (on the Inkbird PID) goes off. If I toggle my manual switch to OFF, of course the element goes off. When the process variable drops below my set variable the element comes on and again and will continue to heat until i turn the manual switch off again.

I ran the auto-tune function and it still continued to heat. I eventually just cancelled the auto-tune

Any suggestions? is my relay junk? If it was faulted, wouldn't the relay always be on regardless of whether the PID is signaling to do so?

I would also appreciate any tips on configuring the Inkbird PID. I will post back with how I have it at the moment.

Thank you

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)