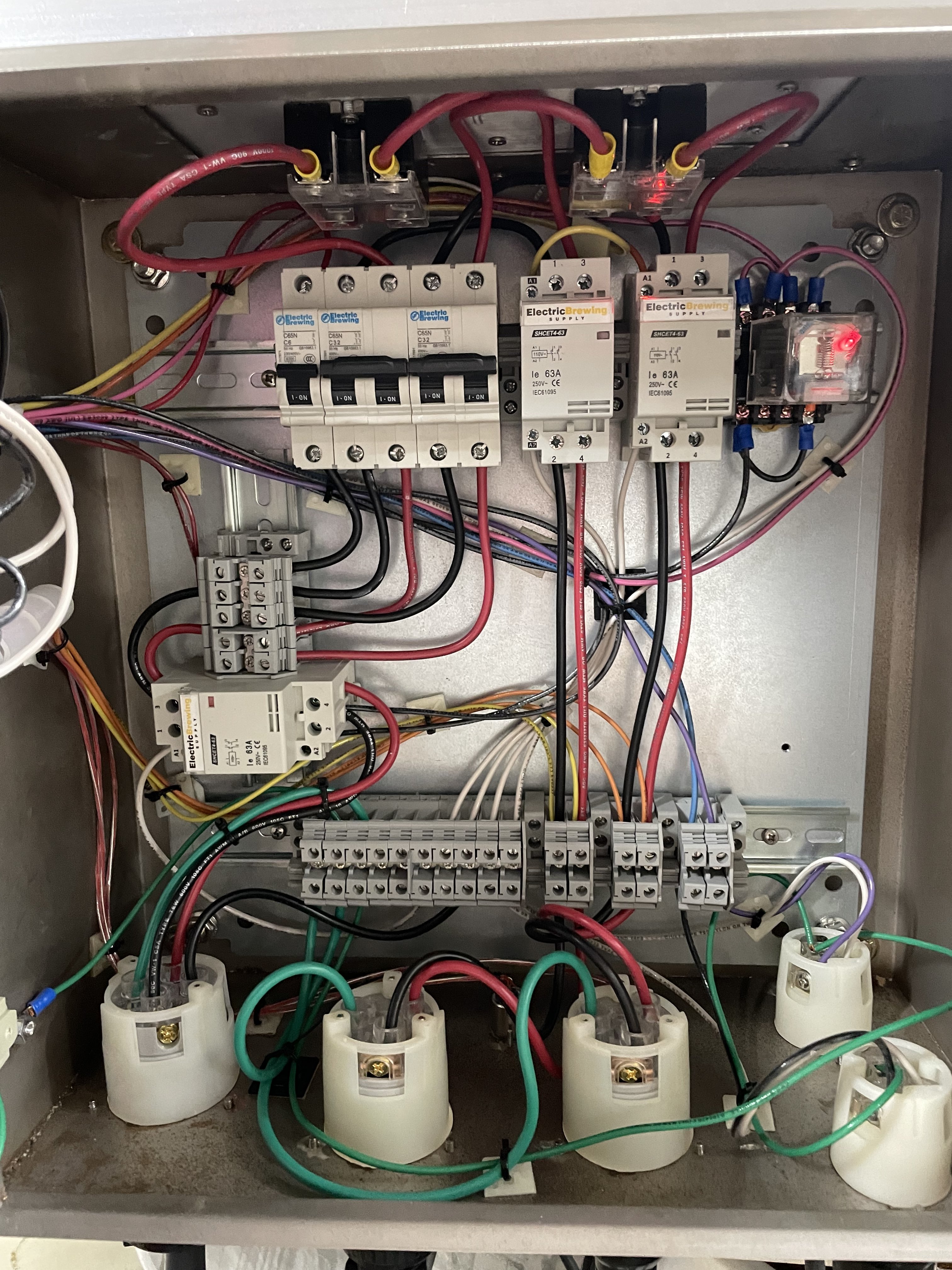

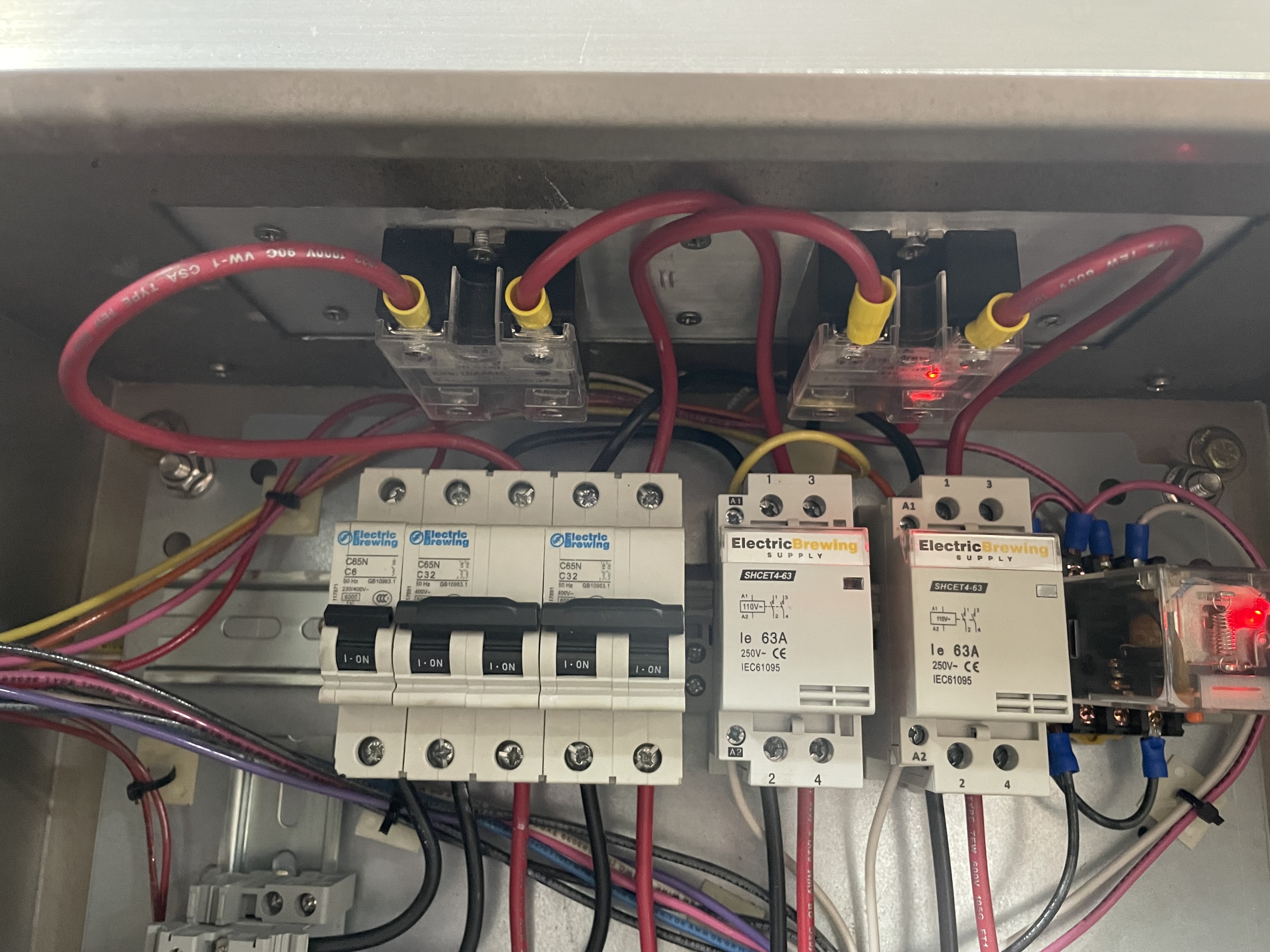

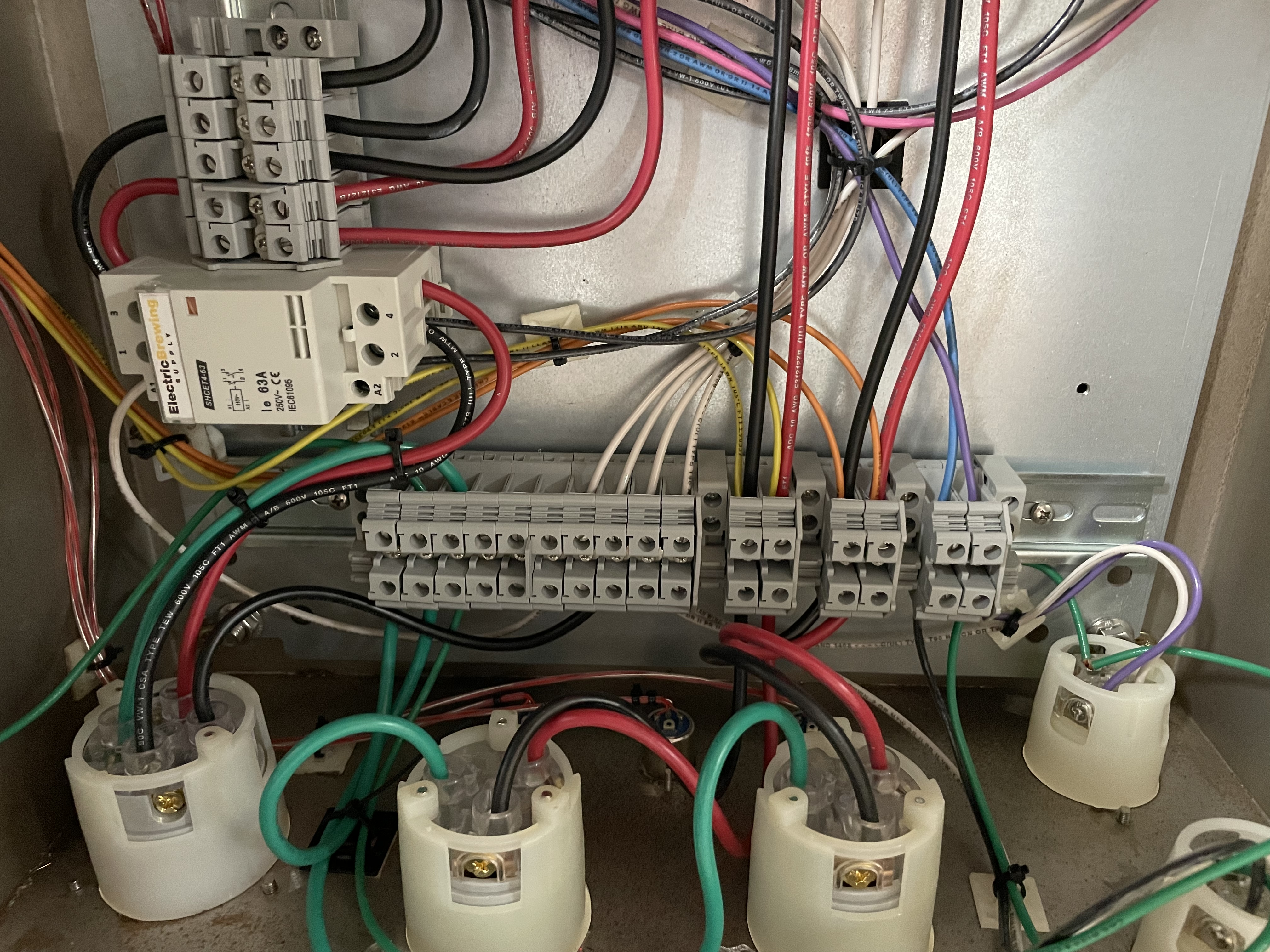

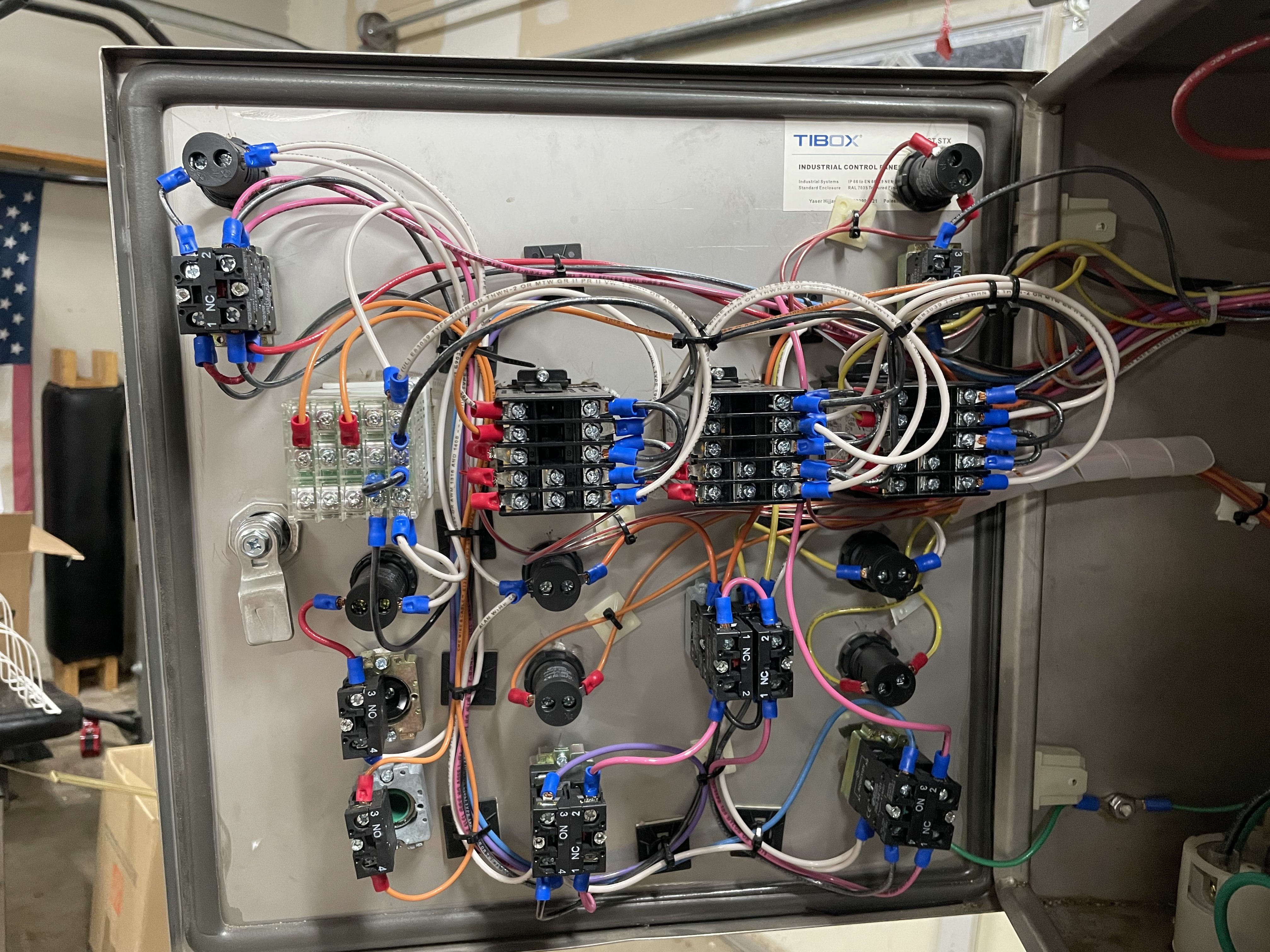

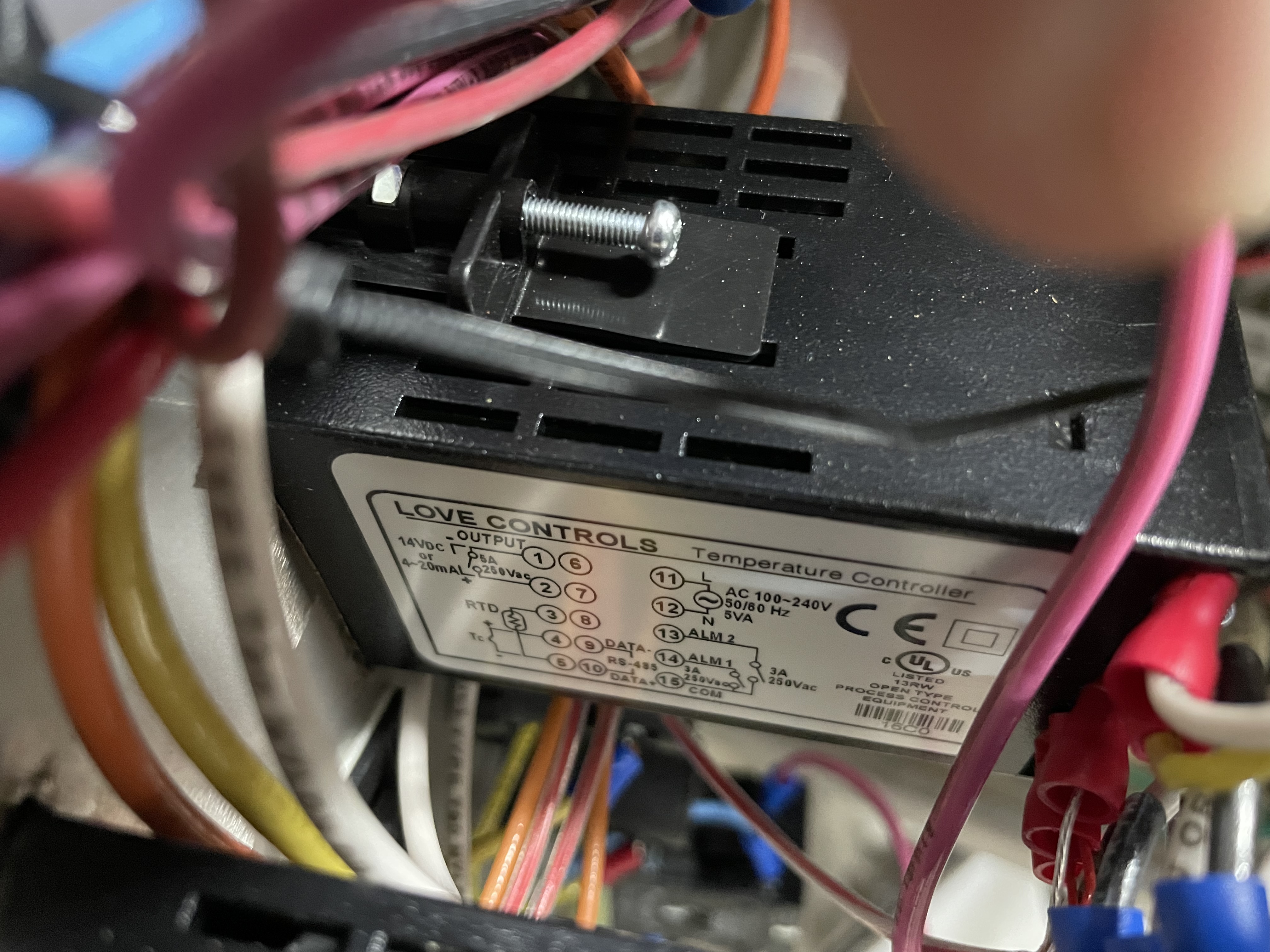

I recently purchased a second hand electric brewing supply 30amp panel and Im having issues with the Love Controls PID’s. Curious if anyone has any advice for the issues below.

1) RTD probe temps fluctuate constantly. I’ve tried adjusting the deviations in settings, but when checking against accurate thermometers the PID readings consistently overshoot on heat up and undershoot when liquids are cooled.

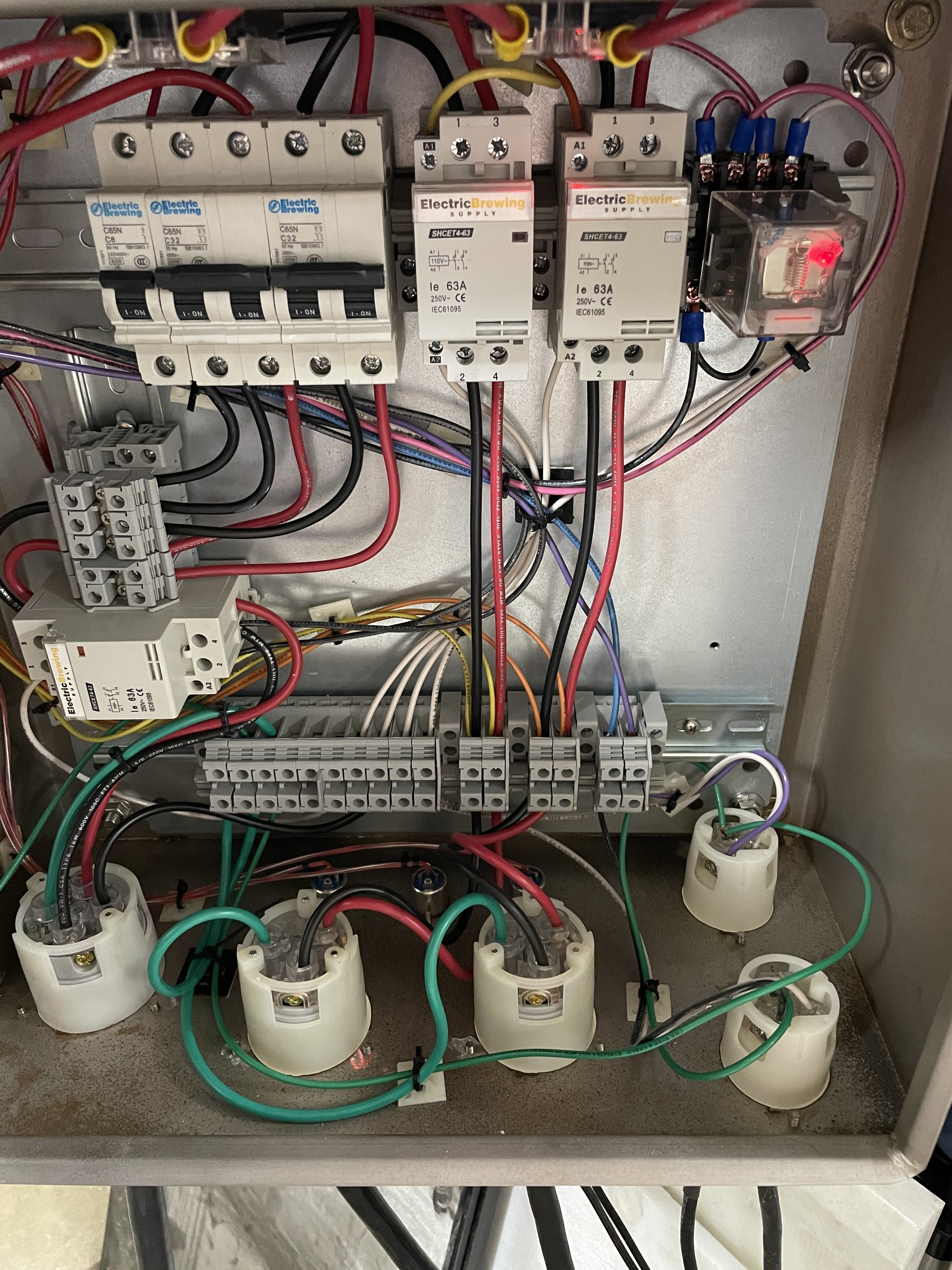

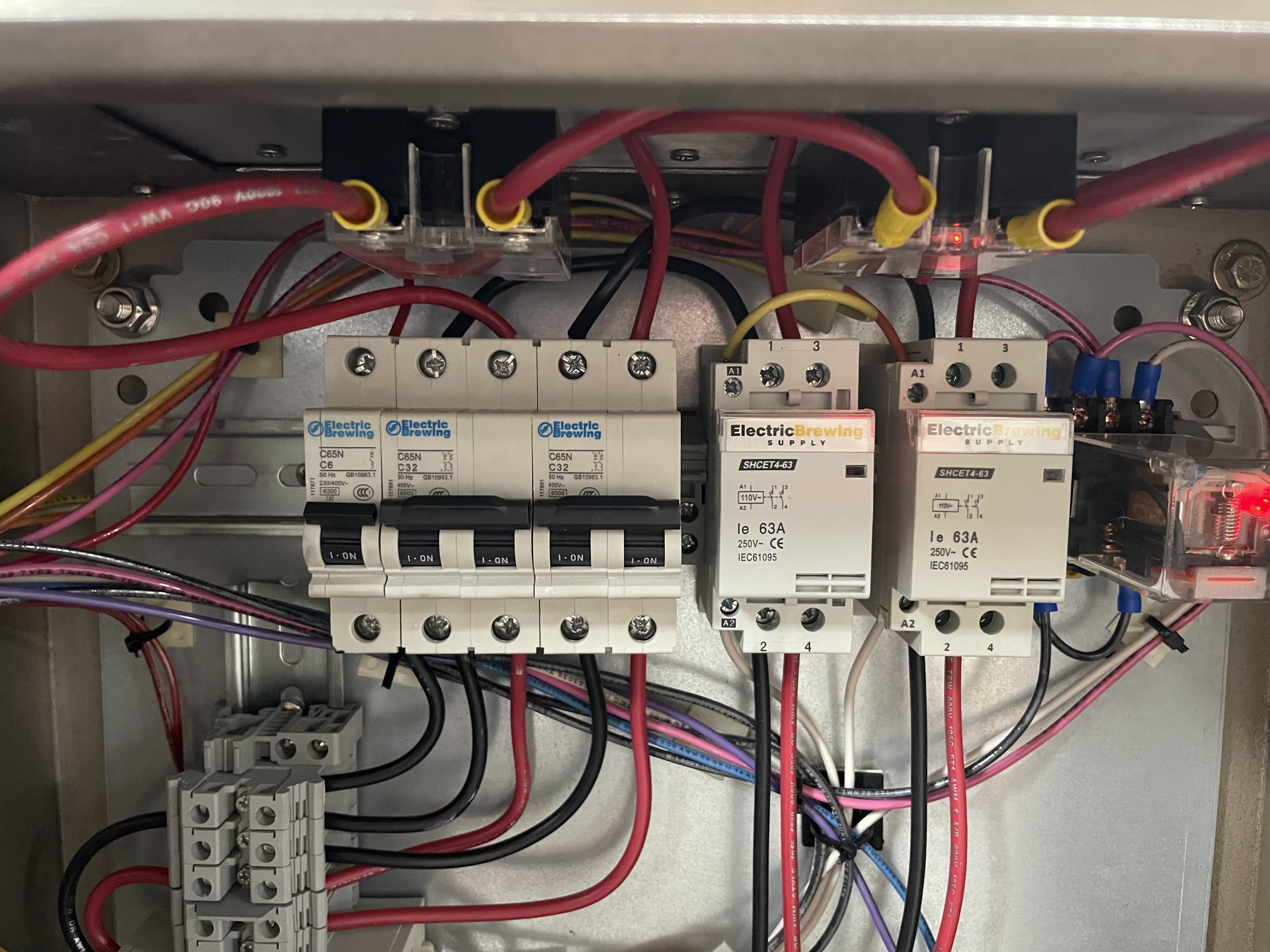

2) The boil controller will not reduce output percentage when set in manual mode. I’ve set the controller in manual mode within settings, but when temp hits set point and I adjust output percentage, the element continues to fire at 100%.

3) Again with the boil controller, I’ve tried testing the “stop” mode when operating in manual, but the element continues to fire. The output LED on the controller turns off, but the element continues to fire.

I’ve been adjusting about every setting available with no success in remedying the issues above. Any advice would be appreciated before I spend another few hundred to upgrade to auber EZ boil controllers….

Thanks in advance.

1) RTD probe temps fluctuate constantly. I’ve tried adjusting the deviations in settings, but when checking against accurate thermometers the PID readings consistently overshoot on heat up and undershoot when liquids are cooled.

2) The boil controller will not reduce output percentage when set in manual mode. I’ve set the controller in manual mode within settings, but when temp hits set point and I adjust output percentage, the element continues to fire at 100%.

3) Again with the boil controller, I’ve tried testing the “stop” mode when operating in manual, but the element continues to fire. The output LED on the controller turns off, but the element continues to fire.

I’ve been adjusting about every setting available with no success in remedying the issues above. Any advice would be appreciated before I spend another few hundred to upgrade to auber EZ boil controllers….

Thanks in advance.